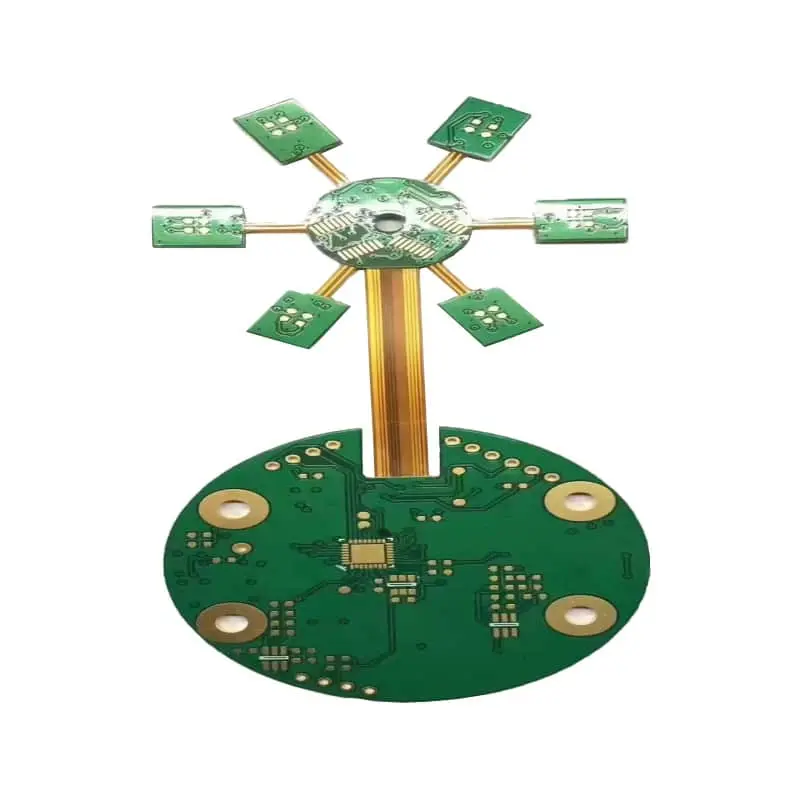

The Industrial Controller PCB can vary significantly in complexity, depending on the specific electronic accessories and application. Some may handle basic tasks like controlling a single motor, while others might orchestrate intricate motions for robotic arms or manage complex industrial processes. This variability necessitates a customized approach to design and standard assembly steps for each Industrial Controller PCB.

The assembly steps of an Industrial Controller PCB begin with a clear vision. Engineers translate user needs into detailed schematics, and meticulously mapped blueprints outlining the board’s functionality. These schematics dictate the specific electronic components required, including integrated circuits (ICS), resistors, capacitors, and other vital elements.

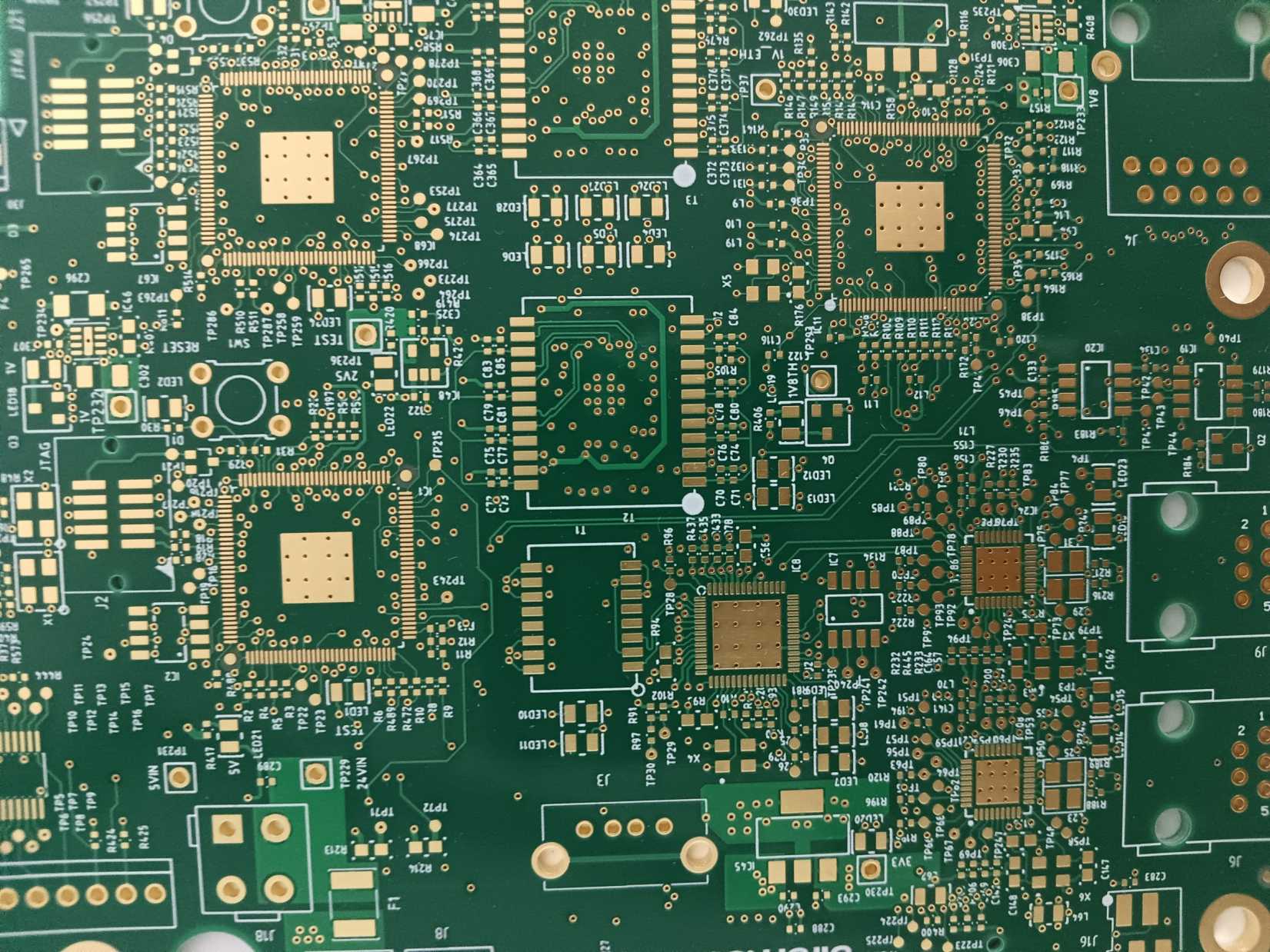

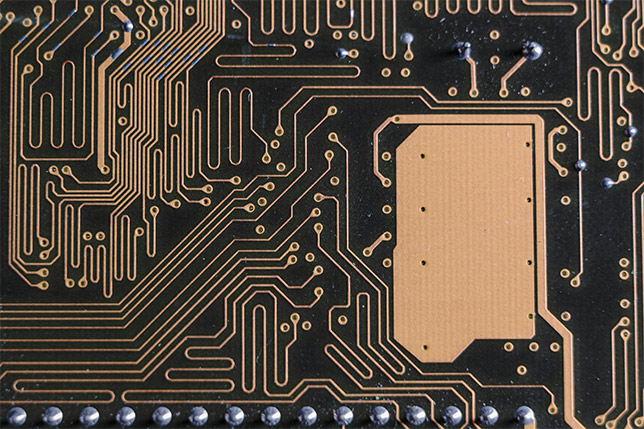

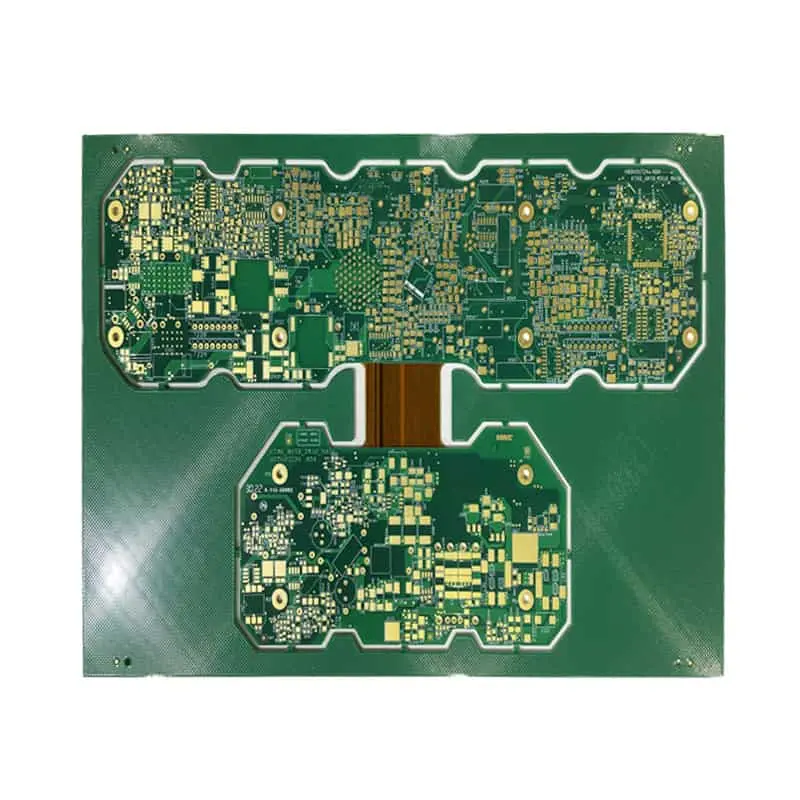

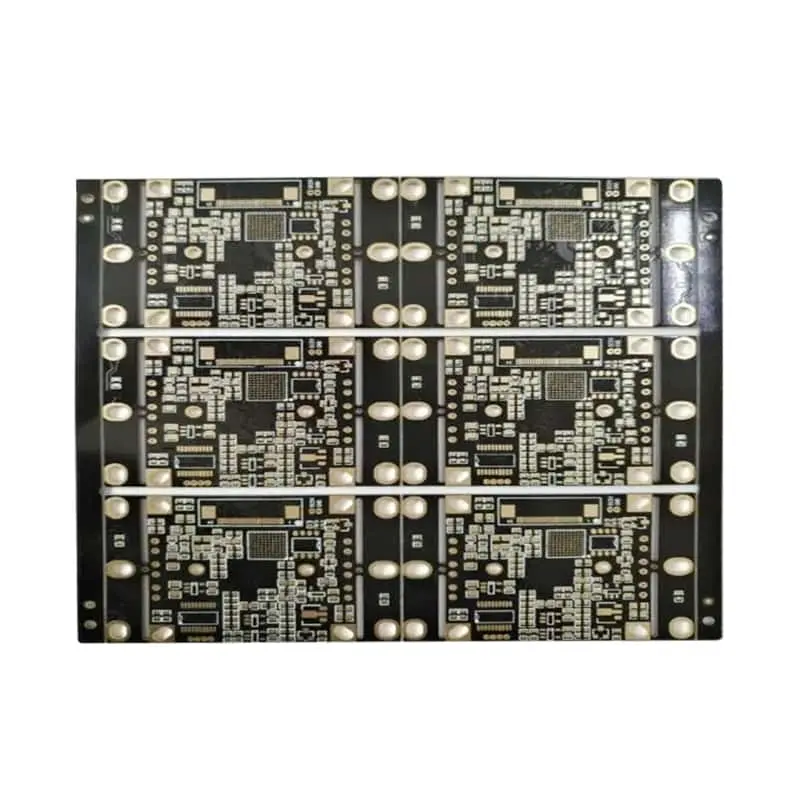

Step 1: PCB Design and Fabrication

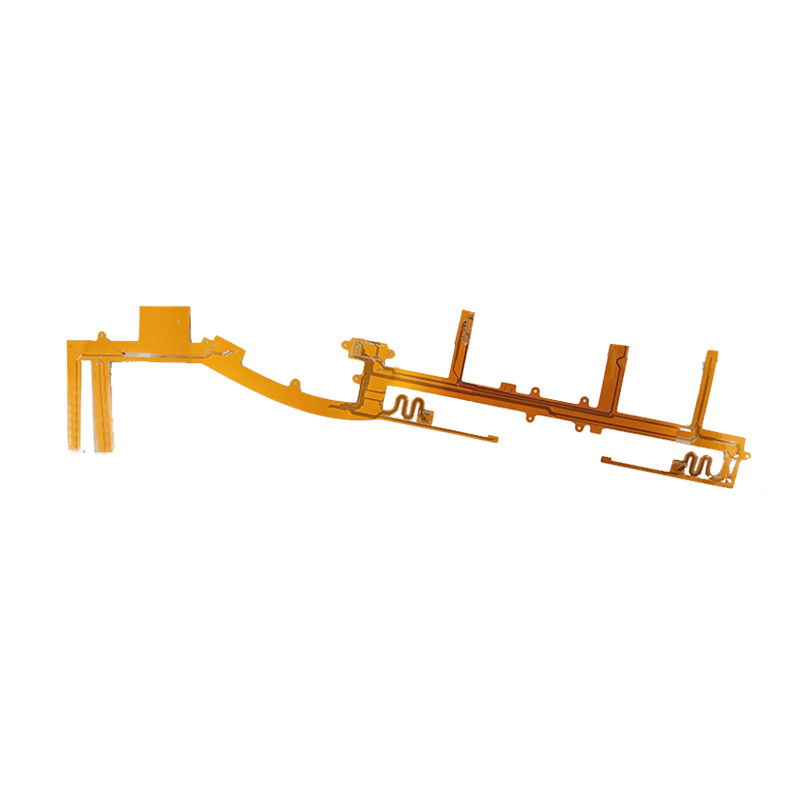

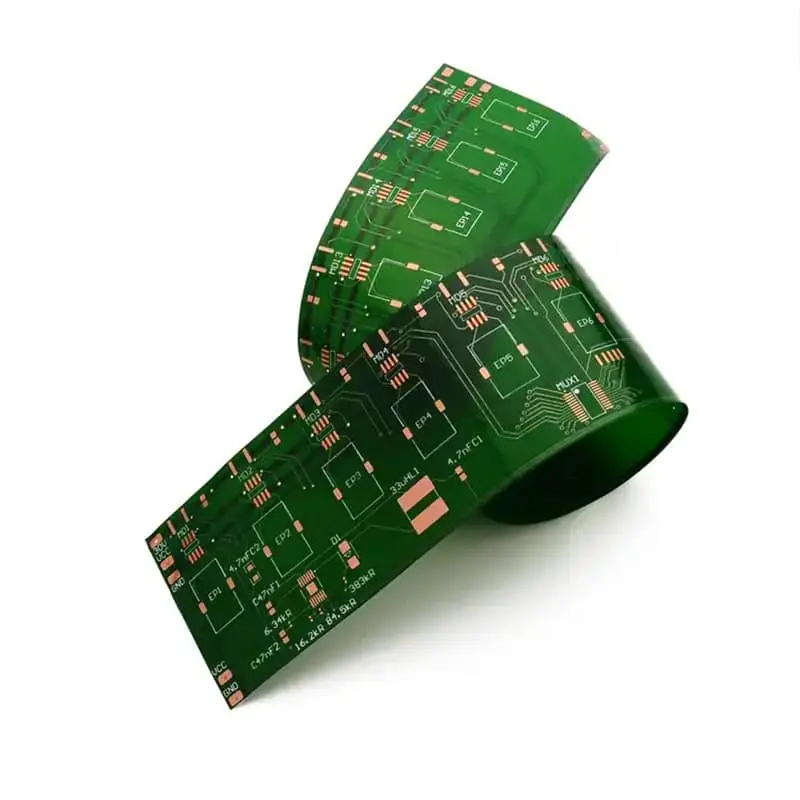

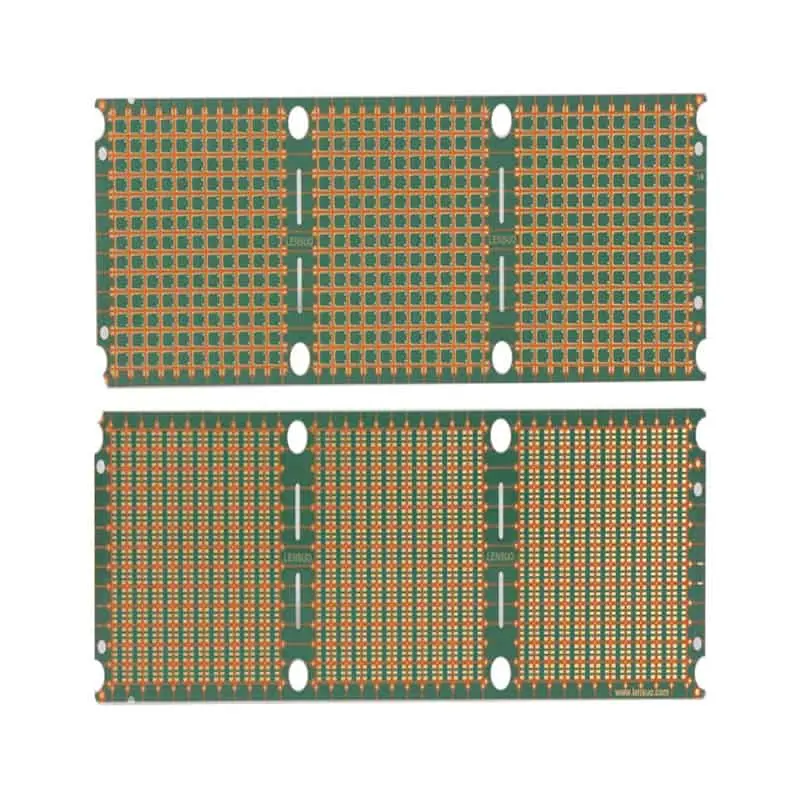

Specialized software allows designers to create a digital representation of the PCB, ensuring optimal component placement for functionality and efficient signal. Once the PCB design is approved, the manufacturing process begins. The first among the assembly steps typically involves photolithography, a precise technique that uses light-sensitive materials to etch copper traces onto a non-conductive base material. The number of copper layers on the PCB can vary depending on the complexity of the design, with multi-layer boards offering greater functionality and space optimization.

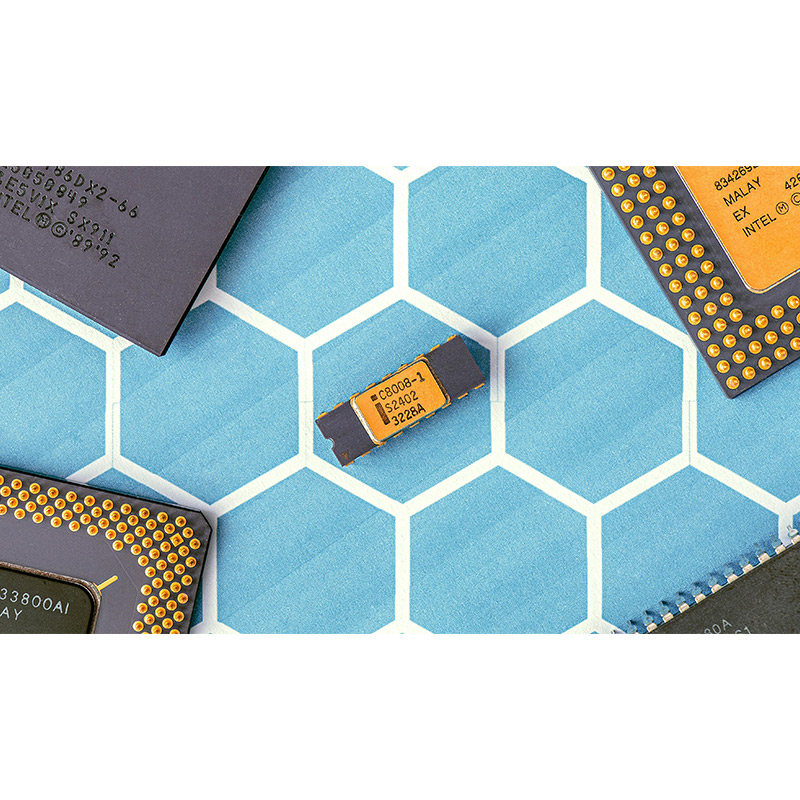

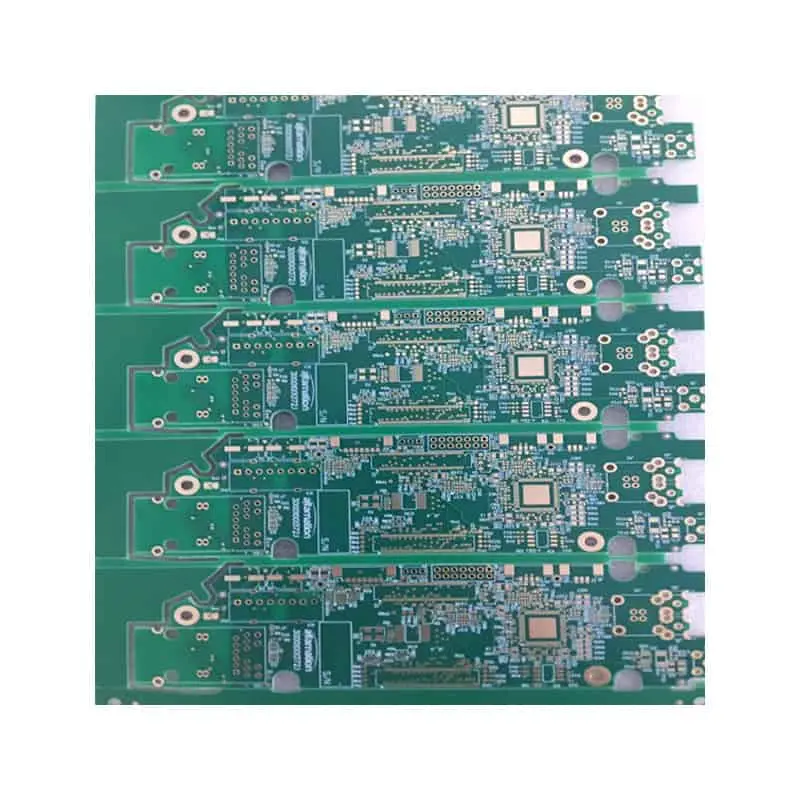

Step 2: Component Procurement and Quality Control

While the PCB itself is taking shape, another one of the crucial assembly steps unfolds: sourcing the electronic components. Reliable PCB assembly companies maintain strong relationships with trusted suppliers, ensuring access to high-quality electronic components. Rigorous quality control measures then come into play, meticulously inspecting every component for functionality and adherence to specifications. This meticulous approach ensures long-term reliability and optimal performance of the finished Industrial Controller PCB.

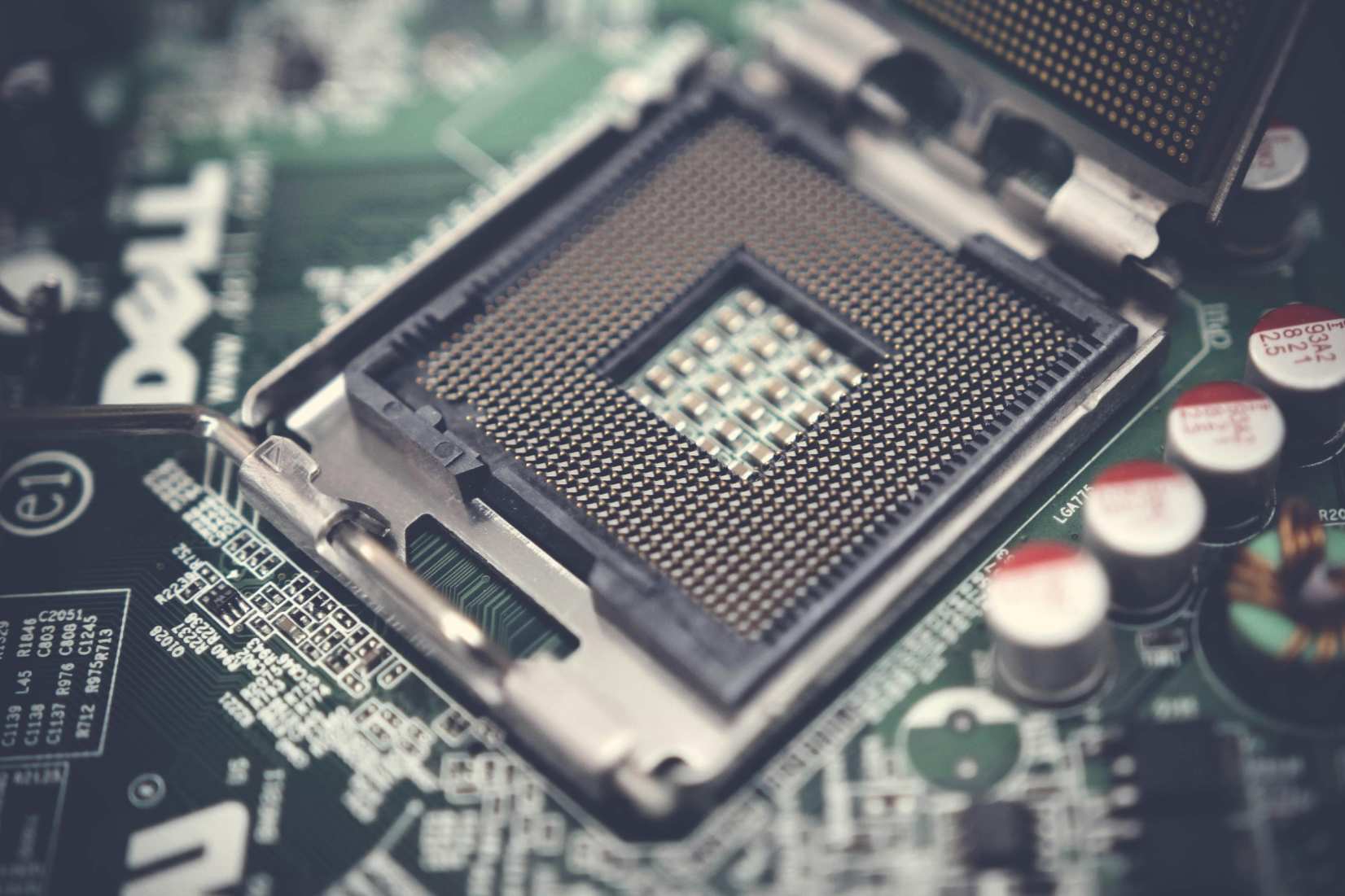

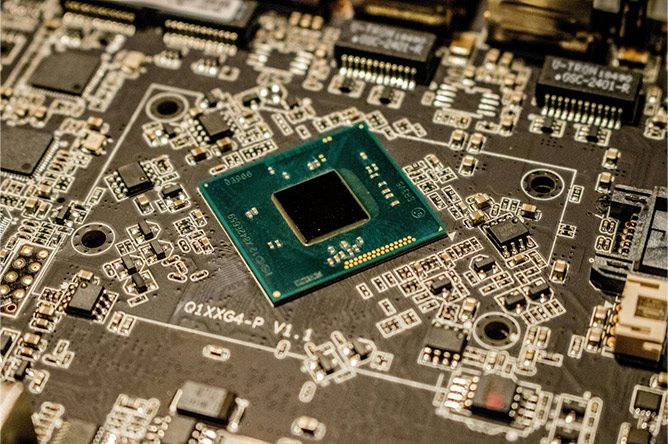

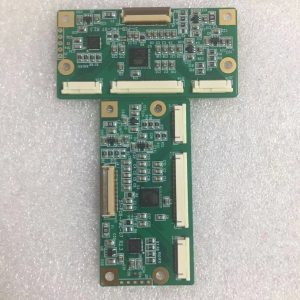

Step 3: Soldering and Assembly

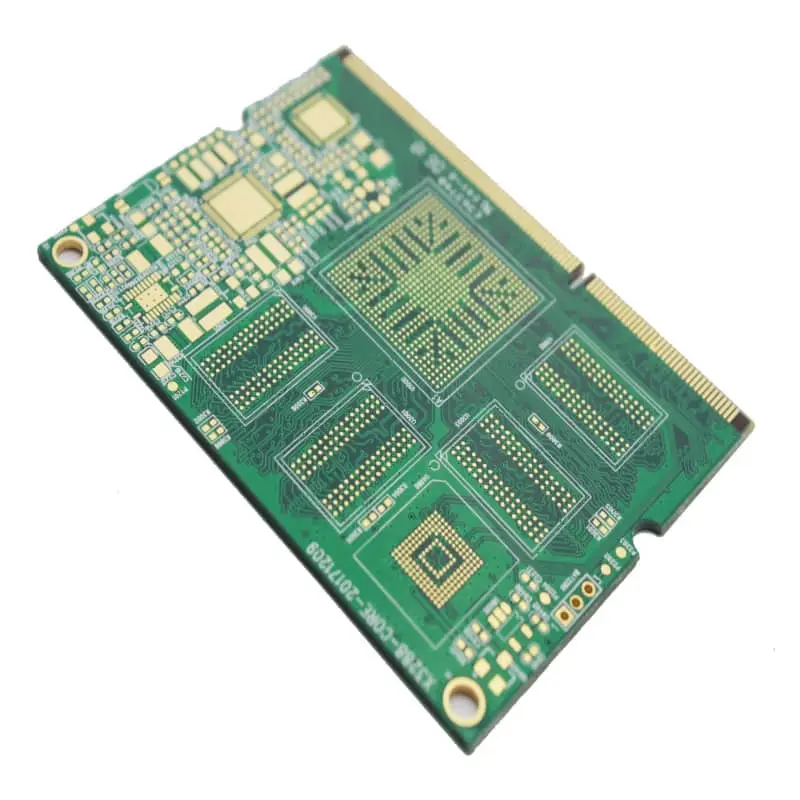

With the PCB fabricated and components quality-checked, the magic of assembly begins. Highly skilled technicians employ precise techniques to solder each component onto designated pads on the PCB. This process requires meticulous attention to detail, ensuring secure connections and optimal electrical performance. Many leading PCB assembly companies, utilize advanced automated soldering equipment and assembly steps for speed and accuracy. However, human expertise remains crucial for complex components or intricate assembly procedures.

Step 4: Inspection and Testing

Once assembled, the Industrial Controller PCB undergoes rigorous testing to ensure flawless functionality. Advanced electrical testing equipment meticulously verifies each connection and component, identifying any potential issues. This multi-stage testing process guarantees that the PCB meets all performance specifications and is ready to take on its role within the industrial environment.

Step 5: Programming and Final Touches

For many Industrial Controller PCBs, the final step involves programming. Specialized software programs the on-board micro-controllers, dictating the specific actions the PCB will take in response to external inputs. This programming process is crucial for ensuring the PCB seamlessly integrates with the electronic accessories broader industrial setup. Once all testing, programming, and assembly steps are complete, the Industrial Controller PCB is carefully packaged for safe transport.

Why Choose PCBCOMING for Industrial Controller PCB

The assembly of an Industrial Controller PCB is a complex and multifaceted process. Here are some of the reasons why you should choose PCBCOMING for your electronic accessories and components needs:

- Expertise: The team at PCBCOMING has extensive experience in designing and assembling industrial controller PCBs for various applications.

- Quality Commitment: PCBCOMING is committed to maintaining the highest standards throughout the process, from component selection to final testing.

- Technical Support: PCBCOMING’s team is ready to answer any questions or concerns you may have during the design and assembly process.

- Turnkey Solutions: PCBCOMING offers complete turnkey solutions, handling everything from initial design consultation to final PCB delivery.

- Advanced Capabilities: PCBCOMING possesses the latest technologies and equipment to ensure efficient and high-quality production of even the most intricate.

Please contact us anytime to learn more about our products and PCB solutions.