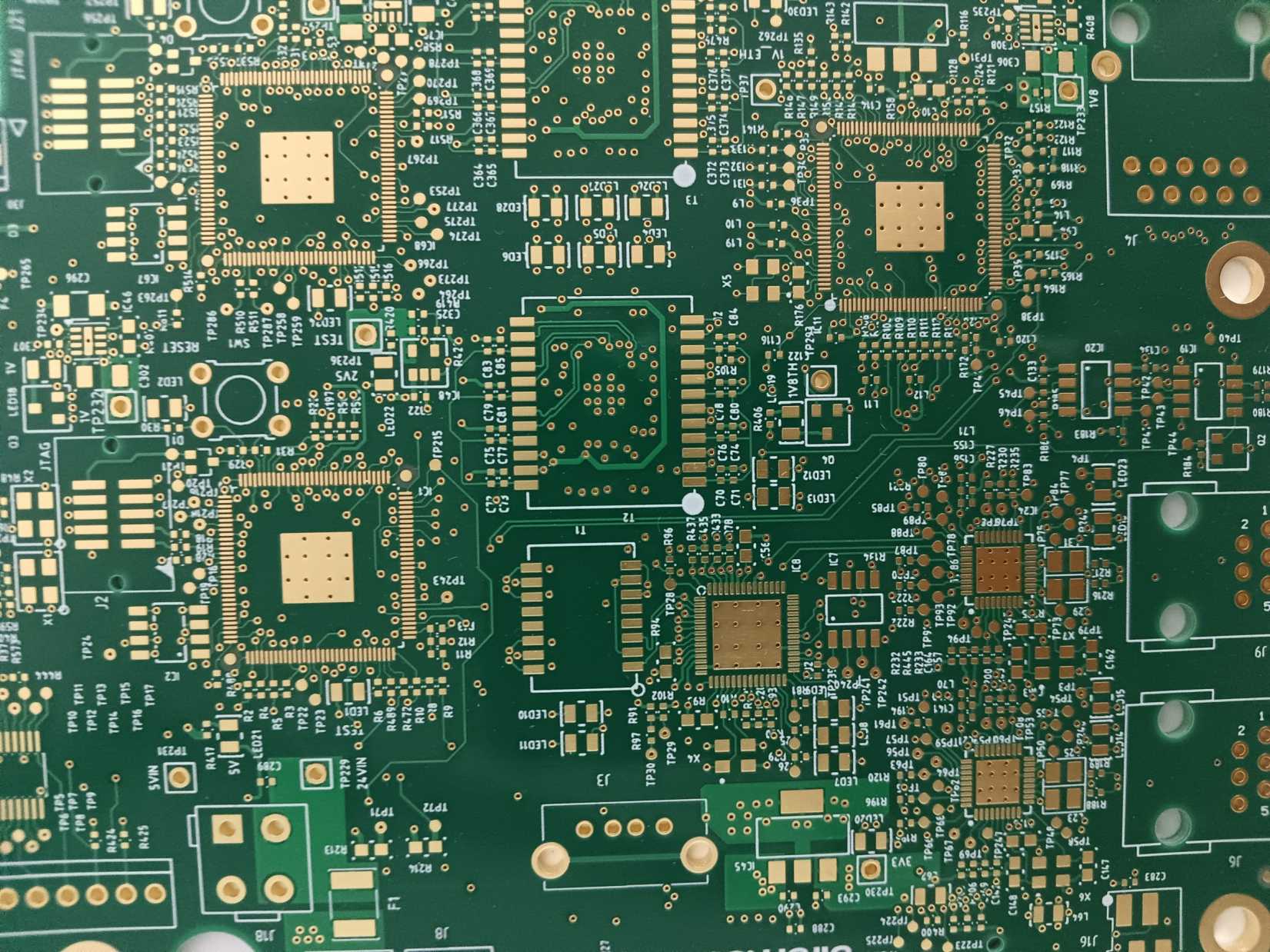

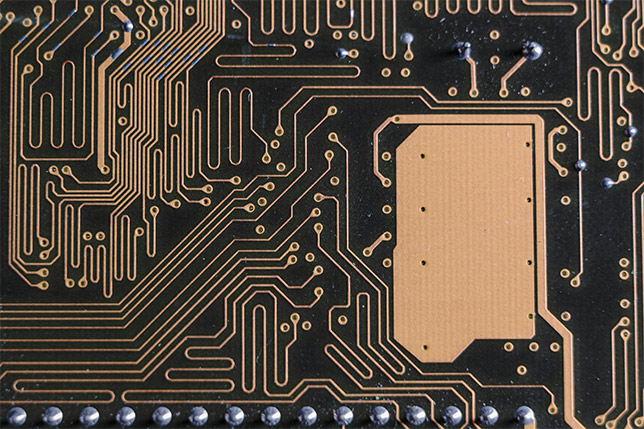

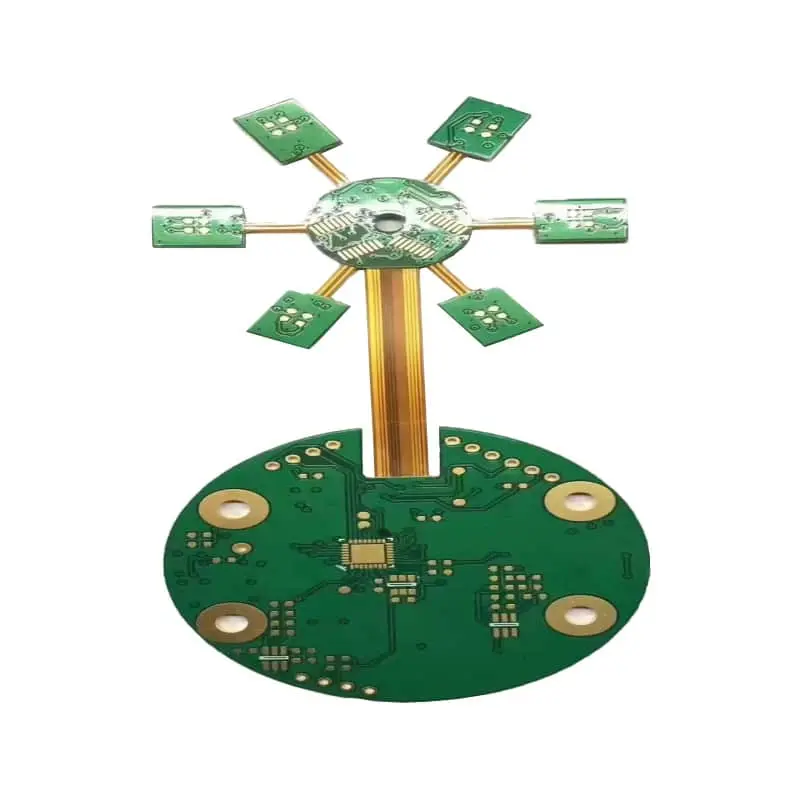

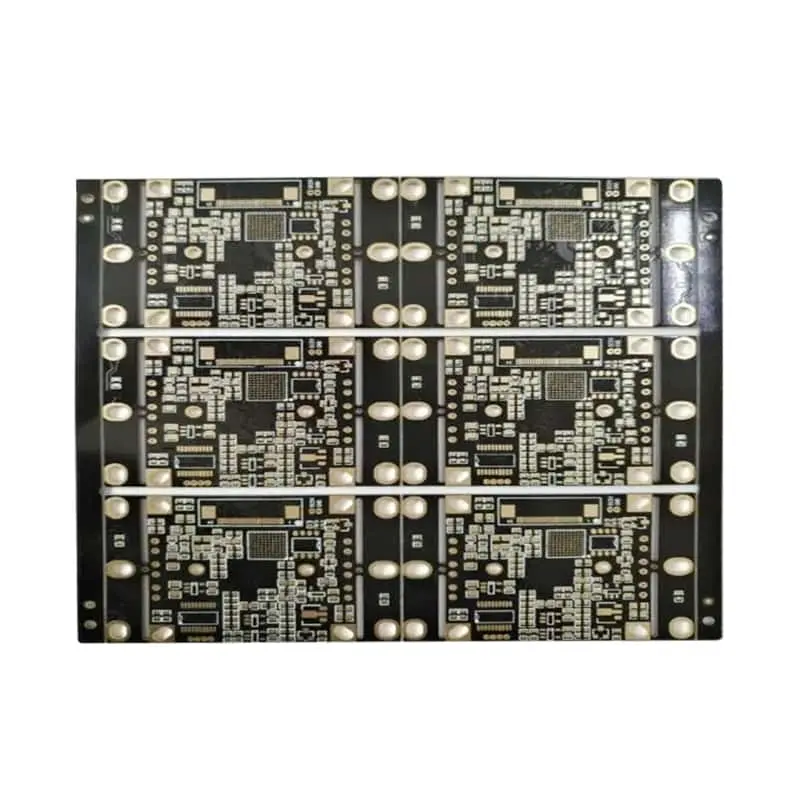

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices, from consumer gadgets to advanced industrial systems. The choice of materials used in a PCB greatly impacts its performance, durability, and application. One of the most popular materials for PCB substrates is the FR4 circuit board, especially for high-speed and high-performance designs.

In this article, we will explore the role of the FR4 circuit board, its applications, and why it’s an ideal PCB substrate for PCBComing and its uses.

What is an FR4 Circuit Board?

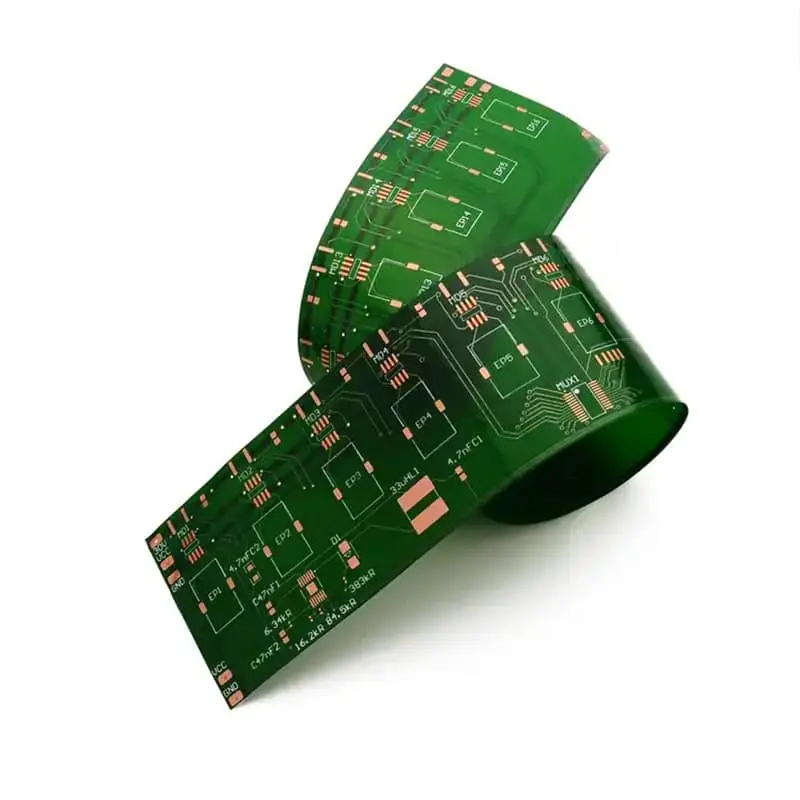

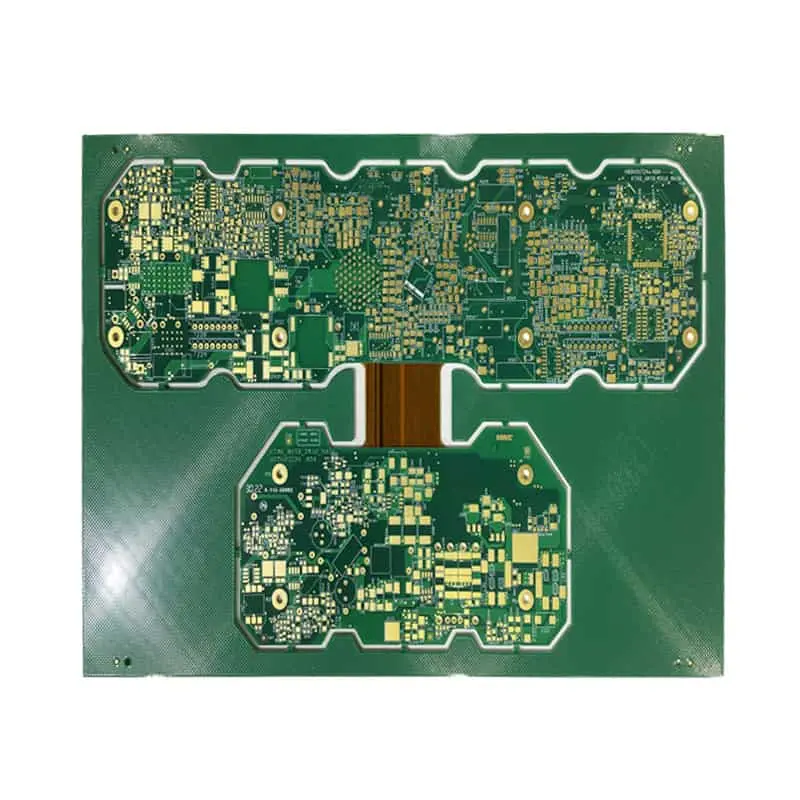

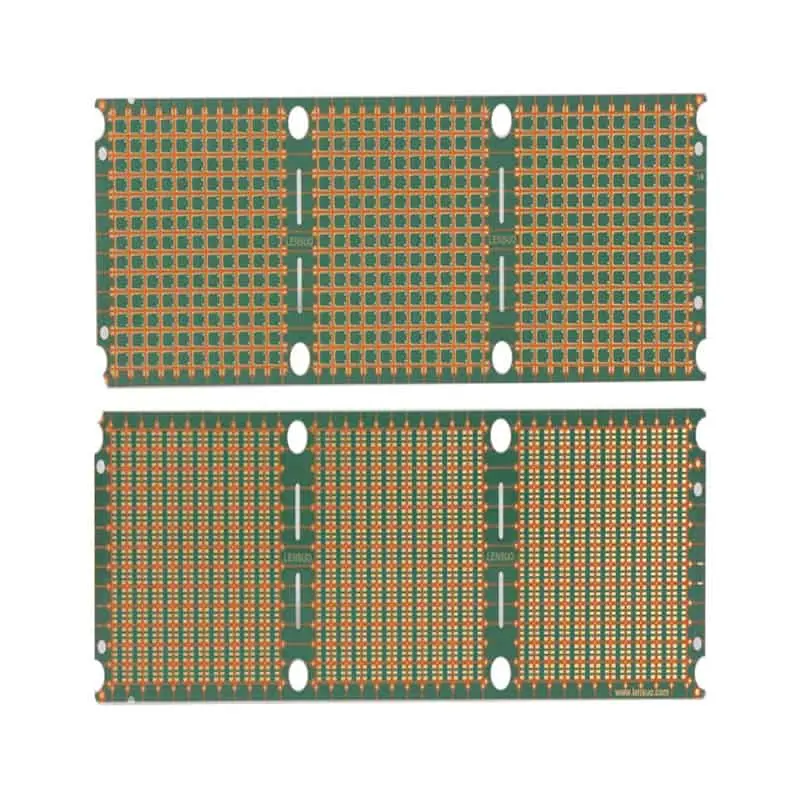

An FR4 circuit board refers to a PCB that uses FR4 as its primary substrate material. FR4 stands for “Flame Retardant,” and it is a type of glass-reinforced epoxy laminate. It offers excellent insulation and mechanical strength, which is essential for ensuring the stability and longevity of electrical circuits.

The FR4 material is widely chosen due to its thermal resistance, moisture absorption capabilities, and cost-effectiveness. With these properties, FR4 becomes a reliable choice for industries like telecommunications, aerospace, and consumer electronics, where long-lasting and stable PCBs are necessary.

Why Choose FR4 for PCB Substrates?

Thermal Stability: FR4 can withstand temperatures up to 140°C, making it an ideal PCB substrate for applications that generate heat during operation, such as high-speed processors or power circuits.

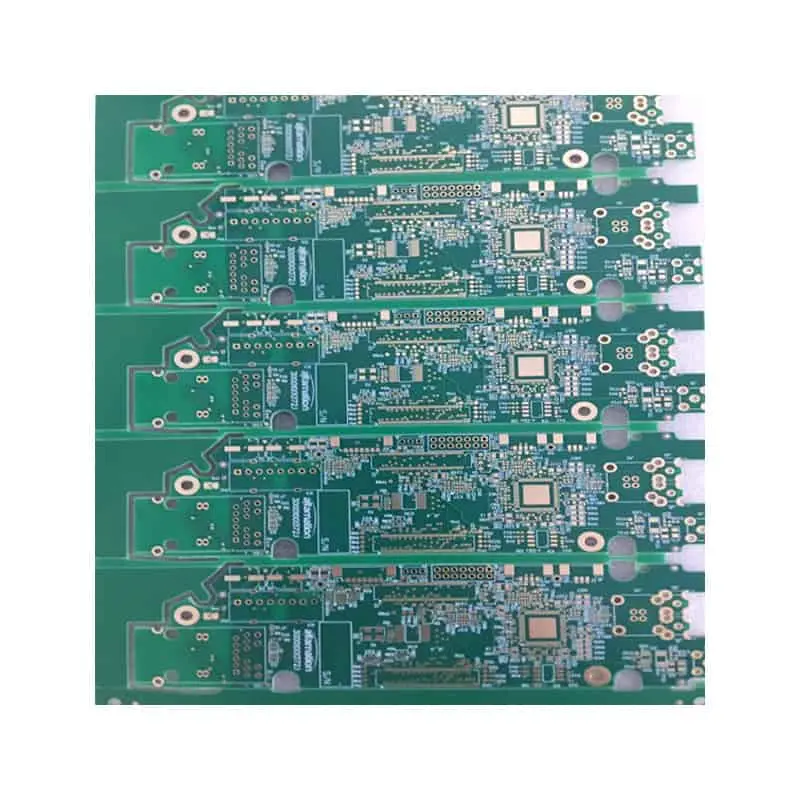

Cost-Effective: Compared to other materials like PTFE or ceramic substrates, FR4 offers an affordable PCB substrate without compromising performance. Its low cost makes it an attractive option for mass-produced electronics and projects that require large volumes of PCBs.

Excellent Insulation: FR4 provides excellent electrical insulation, which is critical in preventing short circuits and ensuring signal integrity. This makes it suitable for high-density circuits and high-frequency applications.

Moisture Resistance: In environments where humidity and moisture are a concern, the FR4 PCB substrate stands out for its low moisture absorption rate. This property ensures that PCBs remain functional even in challenging environmental conditions, which is especially crucial in outdoor or industrial settings.

Applications of FR4 Circuit Boards

Consumer Electronics: From smartphones to laptops, FR4 is a go-to material for creating reliable and efficient PCBs in consumer devices.

Telecommunications: High-speed communication systems require reliable PCBs that can handle fast data transfer rates. FR4 offers the necessary performance to support these demands.

Automotive Systems: With the rise of electric vehicles and advanced onboard systems, the need for durable PCBs has never been higher. FR4 is commonly used in automotive electronics due to its stability and resilience.

Aerospace and Defense: In aerospace and defense applications, PCBs must be able to withstand extreme conditions such as high heat, vibration, and pressure. The properties of FR4 make it a trusted choice for these critical systems.

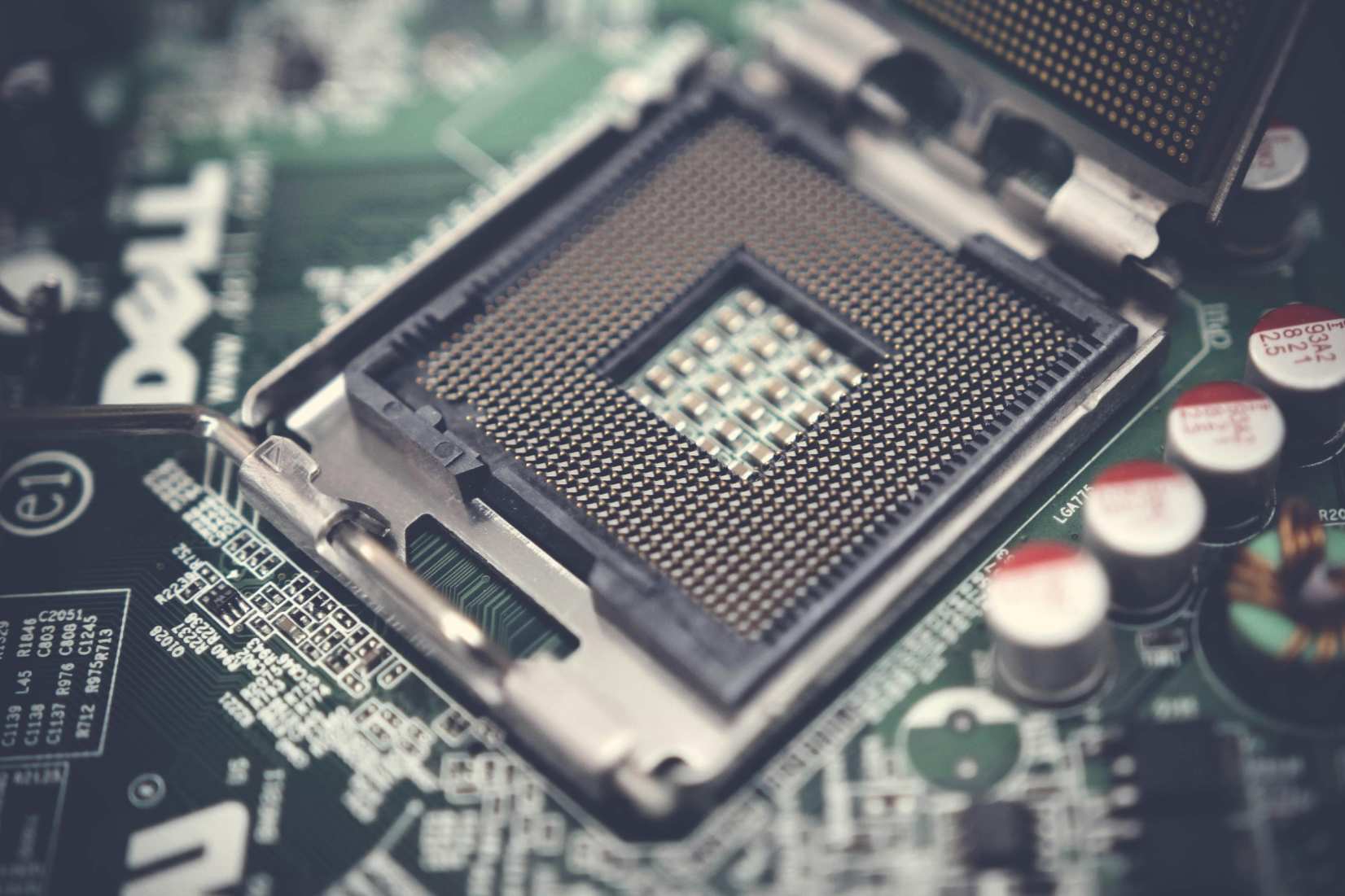

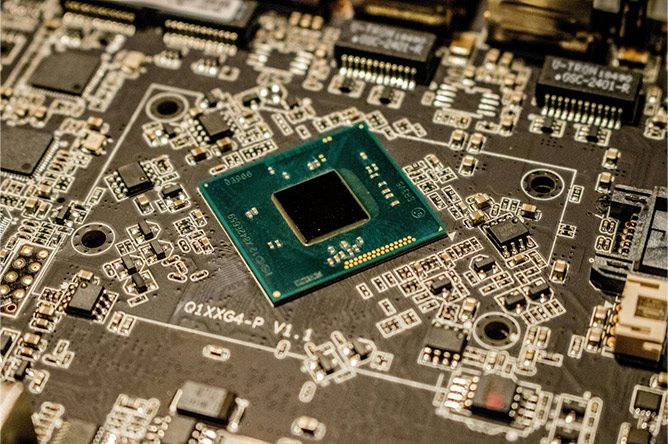

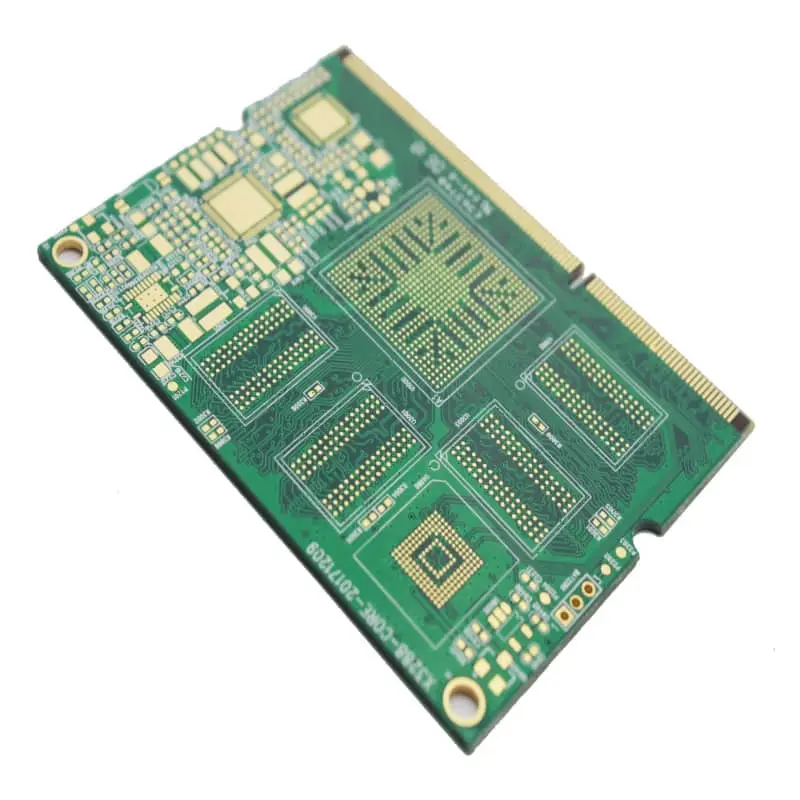

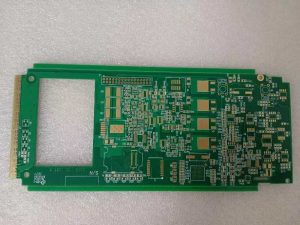

FPGA High-Speed PCB: The Role of FR4 Substrates

In the field of FPGA high-speed PCB design, the choice of substrate is crucial to achieving the necessary speed and signal integrity. Field-Programmable Gate Arrays (FPGAs) are used in high-performance computing systems and require fast data transmission and processing.

For an FPGA high-speed PCB, FR4 substrates provide the necessary insulation and structural support to maintain signal quality while minimizing interference. Additionally, FR4’s ability to withstand high-frequency operation without degradation makes it an ideal material for high-speed digital designs.

When designing a high-speed PCB for FPGA applications, factors like trace impedance, dielectric constant, and signal reflection must be carefully managed. FR4’s consistent dielectric properties ensure that high-speed signals are transmitted accurately, reducing the risk of data corruption or delays.

Limitations of FR4 Circuit Boards

While FR4 circuit boards offer several benefits, they are not without limitations. For applications that require extremely high thermal performance, such as RF and microwave circuits, other materials like PTFE or ceramic substrates may be more appropriate. Additionally, for ultra-high-speed applications where signal integrity is of utmost importance, more advanced PCB materials may be required to reduce signal loss and distortion.

Conclusion

FR4 circuit boards remain one of the most popular choices in the PCB industry due to their balance of performance, cost-effectiveness, and reliability. Whether designing high-speed PCBs or general-purpose electronics, FR4 PCB substrates provide a stable and durable foundation for a variety of applications.

For more details, please contact us!