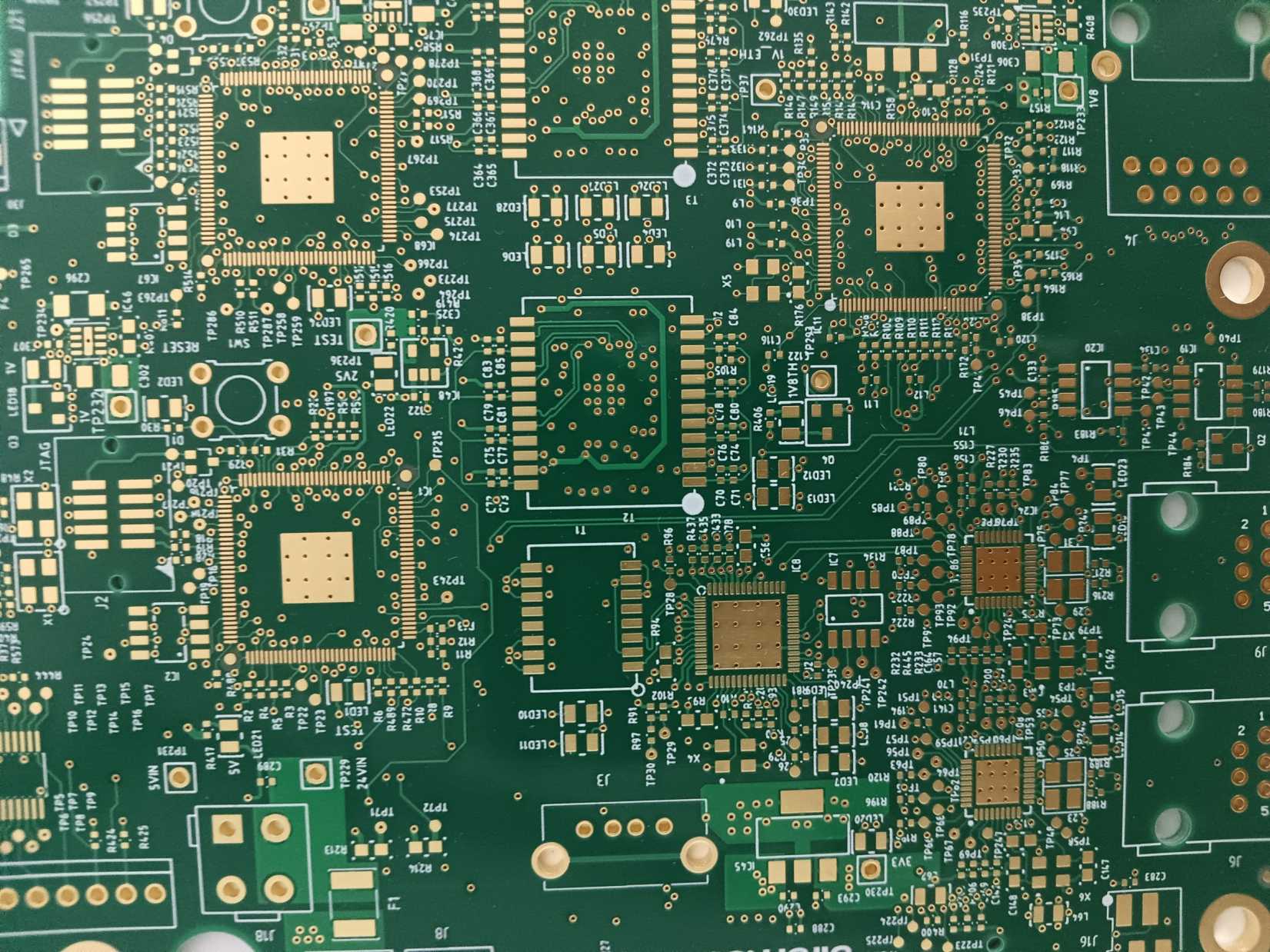

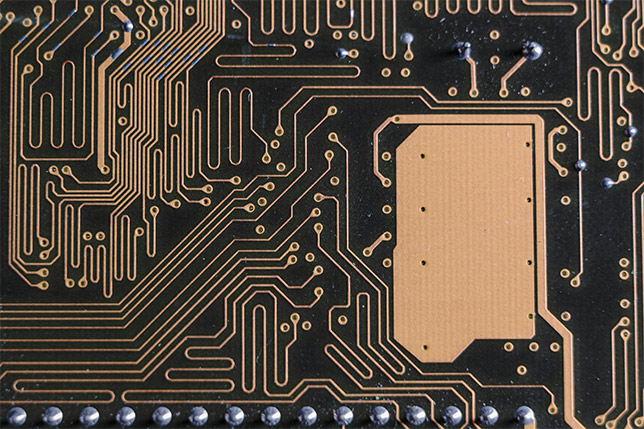

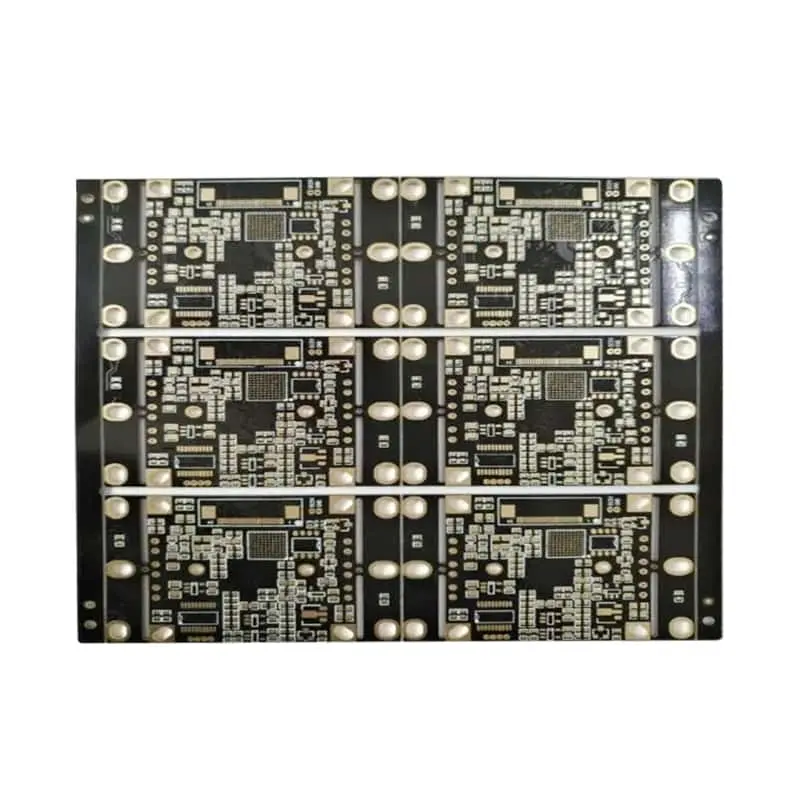

Importance of Vias in PCB Design

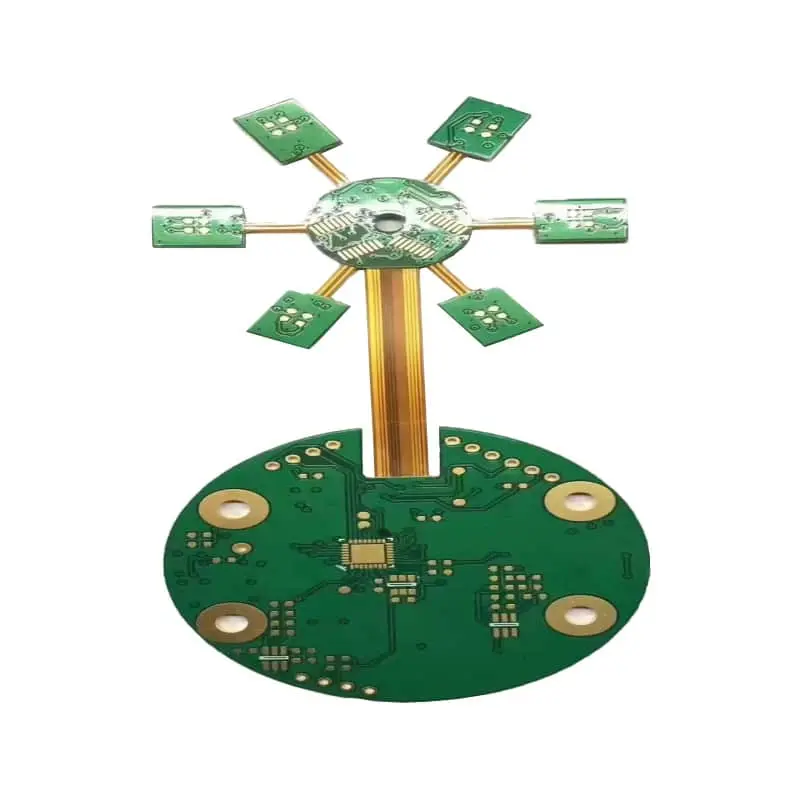

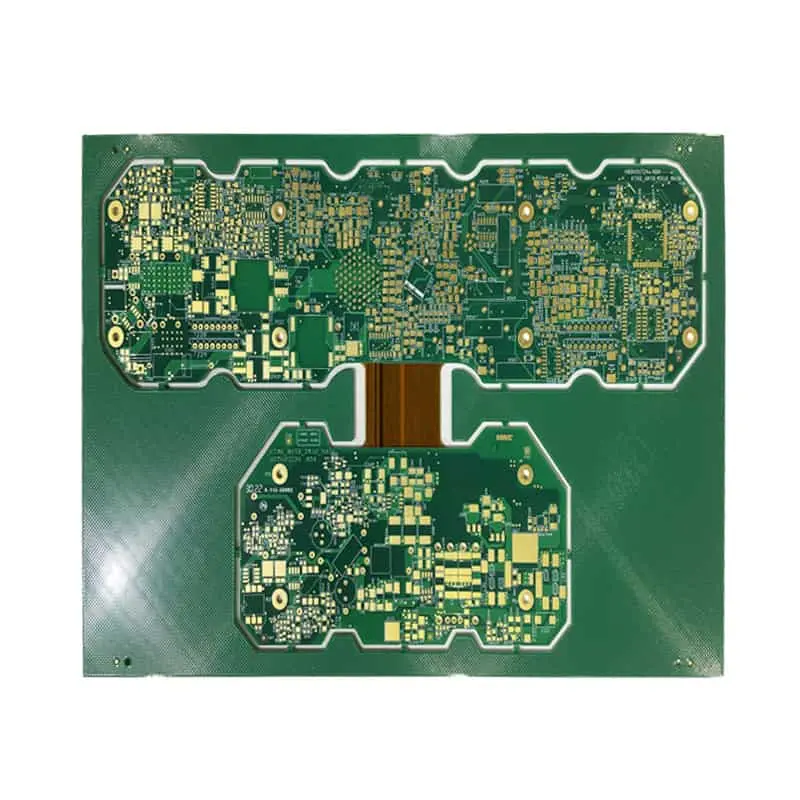

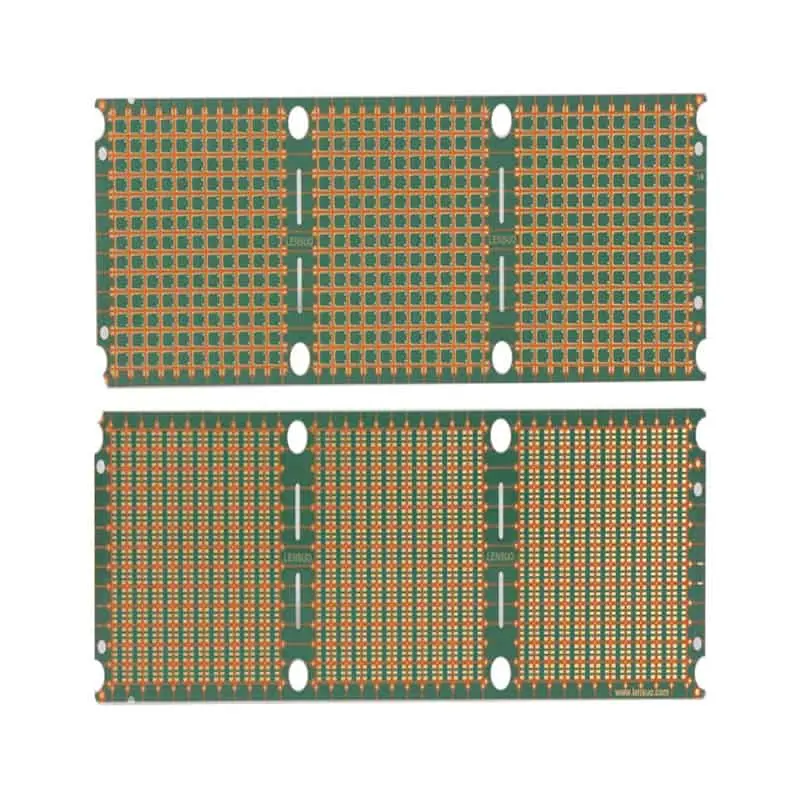

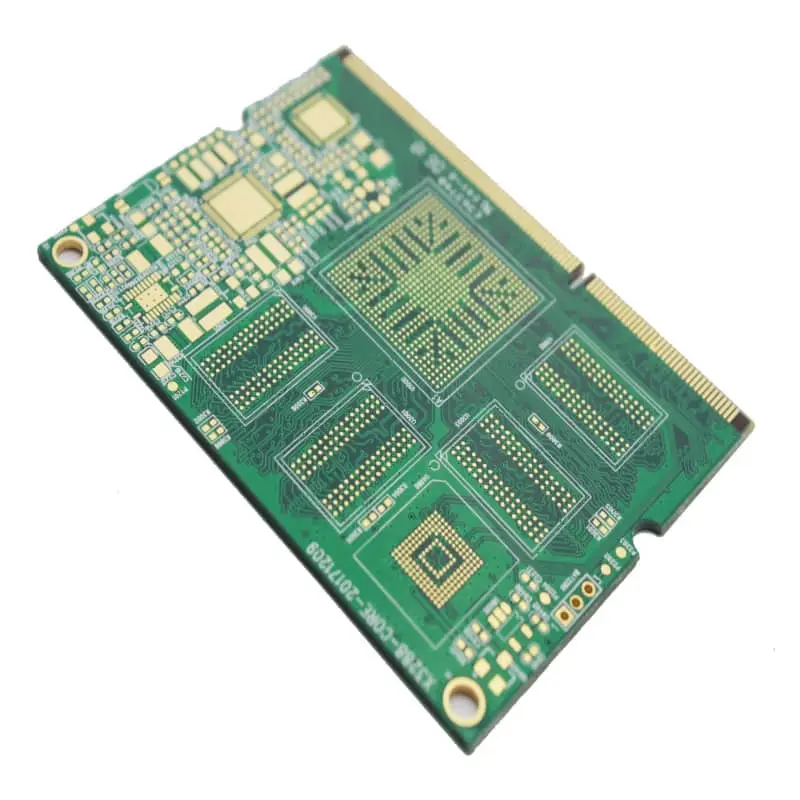

Vias play a pivotal role in multilayer PCBs, facilitating the complex routing required in modern electronic devices. They allow for compact and efficient designs by enabling connections across multiple layers. Proper design is critical for signal integrity and overall device performance.

PCB Via Plating Process

Preparation and Cleaning

Before the plating process begins, the PCB surface must be meticulously prepared and cleaned. This step involves techniques like mechanical brushing, chemical cleaning, and deoxidation to remove any contaminants. Surface preparation ensures that the plating adheres well to the substrate, which is vital for the integrity of the final product.

Plating Techniques

1. Electroless Plating

1. Electroless Plating

The process of electroless plating entails a chemical reaction that deposits a thin layer of metal, typically copper, onto a PCB’s surface without using an electric current. This method guarantees a uniform coating on non-conductive surfaces and through-holes. One of the key advantages of electroless plating lies in its ability to achieve a consistent deposition on intricate geometrical shapes.

2. Electroplating

This process builds on the electroless plating layer, thickening the copper layer and ensuring durability. Electroplating is essential for achieving the desired thickness and electrical properties of the vias.

Inspection and Quality Control

After plating, thorough inspection and quality control checks are performed to ensure the vias meet the required specifications. This includes visual inspections, electrical testing, and sometimes X-ray analysis to detect any internal defects. Maintaining high-quality standards is essential to prevent failures in the final product.

Applications and Future Trends

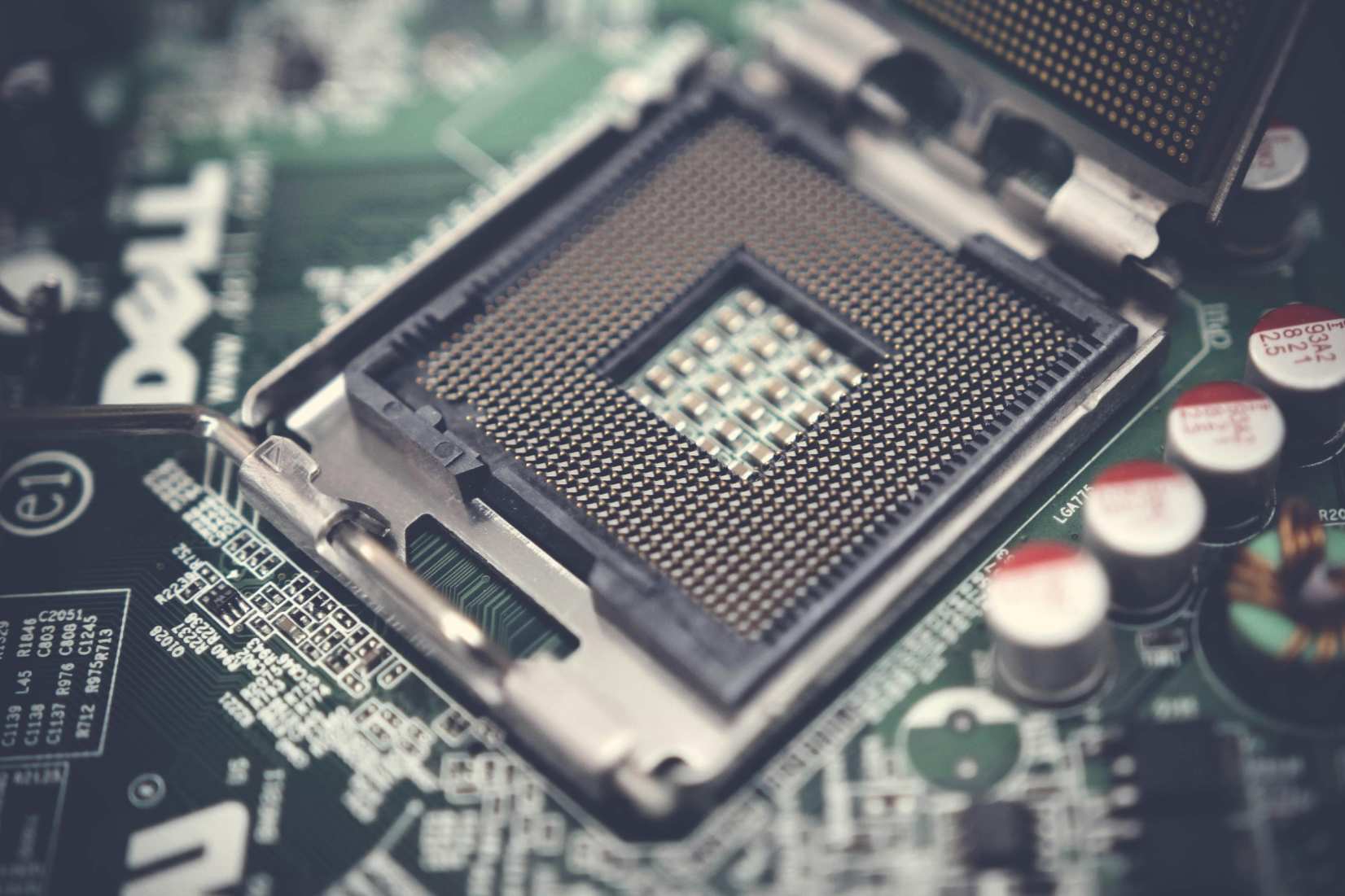

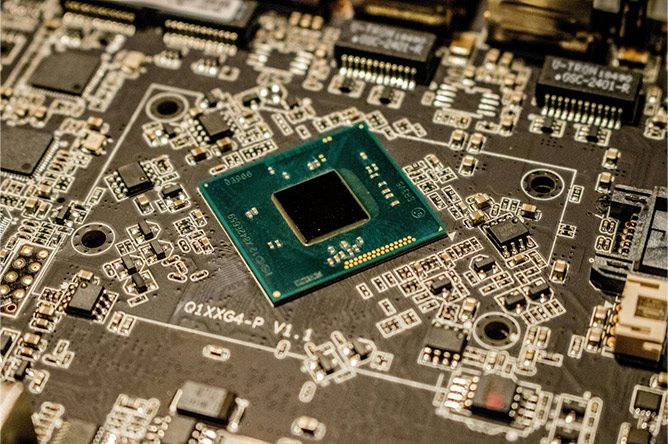

Applications in Various Industries

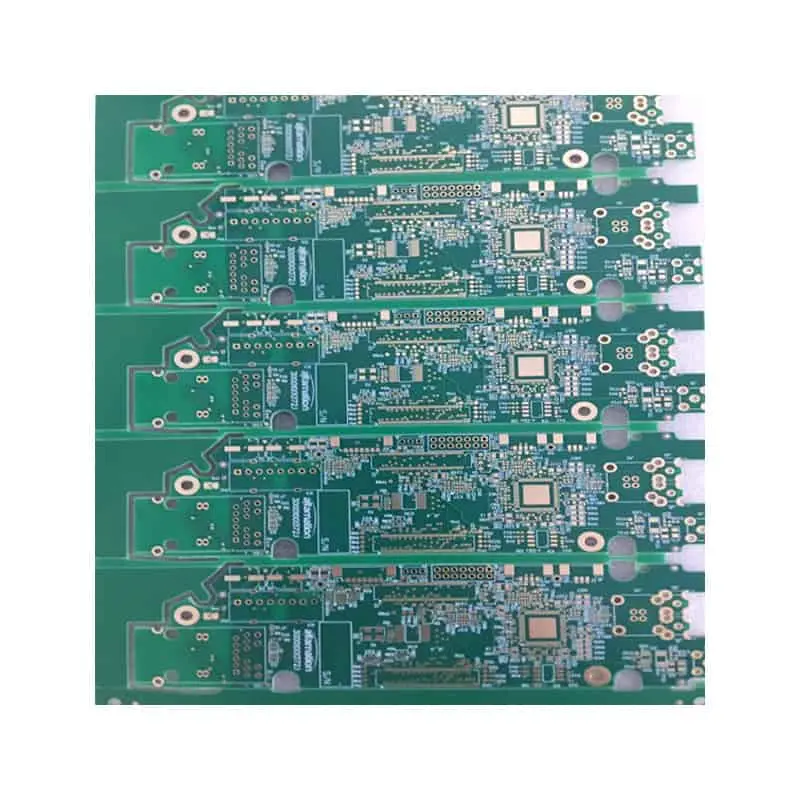

PCB via plating is utilized across numerous industries. In electronics, it supports high-density interconnections necessary for consumer electronics like smartphones and laptops. In aerospace, PCB reliability is critical for navigation and communication systems.

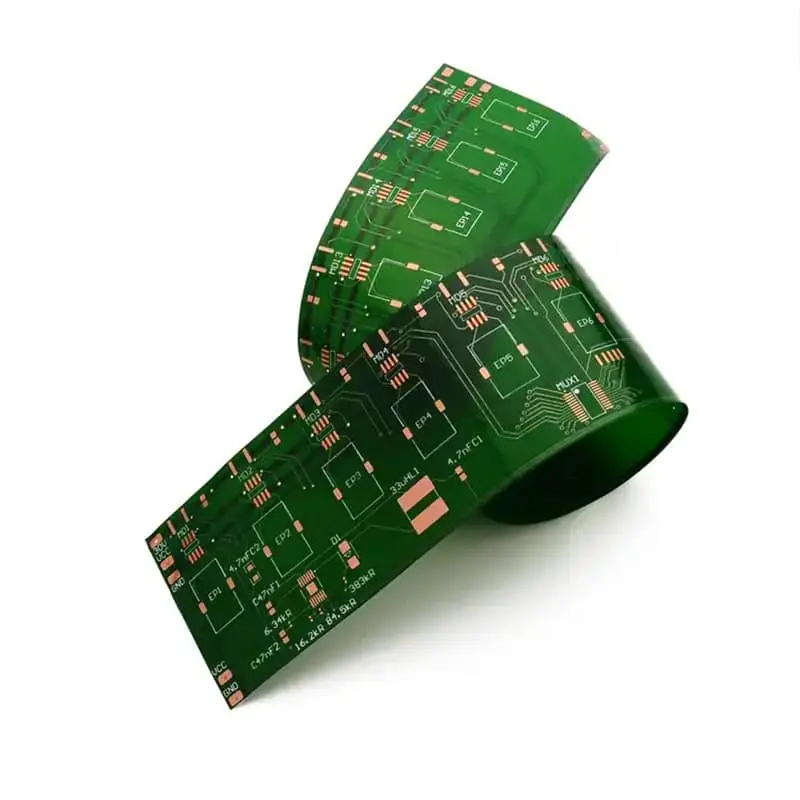

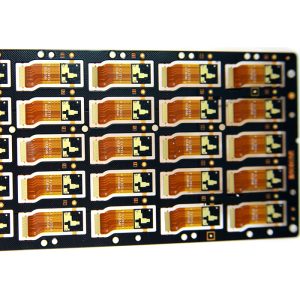

Innovations and Future Trends

The PCB industry is continuously evolving, with innovations aimed at improving efficiency and sustainability. Emerging technologies such as micro vias—smaller vias used for finer pitch components—are gaining popularity. Additionally, there is an increasing emphasis on environmental considerations, with industry leaders exploring eco-friendly materials and processes to reduce the environmental impact of PCB manufacturing.

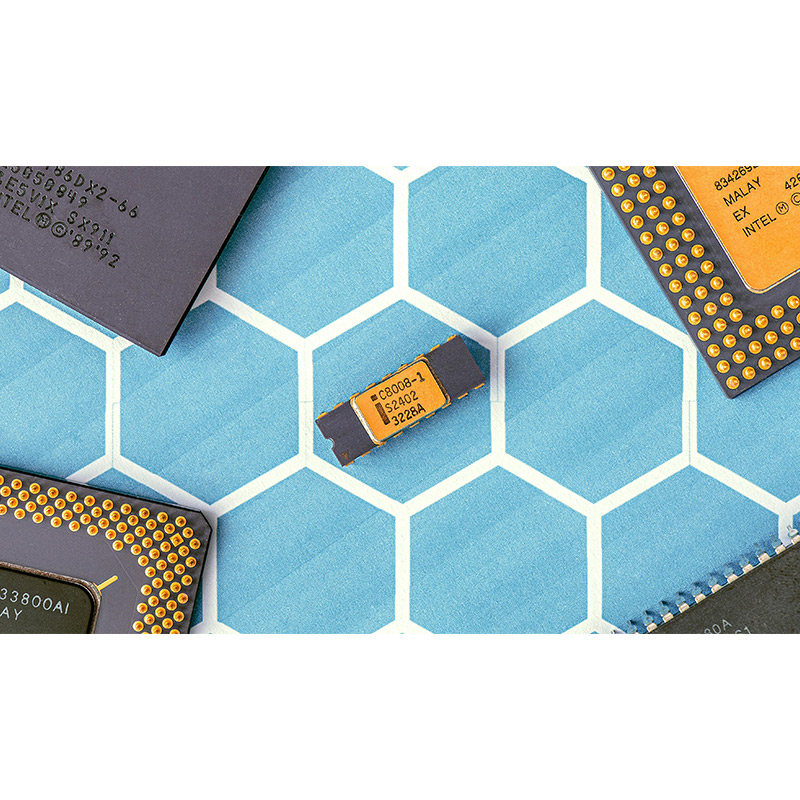

Personal Insights

From my perspective, having observed the industry’s evolution, the shift towards miniaturization and higher efficiency is evident. The transition to advanced materials and techniques, like microvias and eco-friendly processes, is not just a trend but a necessity driven by the demands of modern electronic devices and environmental responsibilities. Keeping pace with these changes is crucial for staying competitive in the ever-evolving PCB landscape.

In summary, PCB via plating is a complex yet vital process in the manufacturing of modern electronic devices. From understanding via types to mastering plating techniques and anticipating future trends, comprehensive knowledge in this area is essential for anyone involved in PCB design and manufacturing.

If you have any questions or product needs, please contact PCBCOMING.