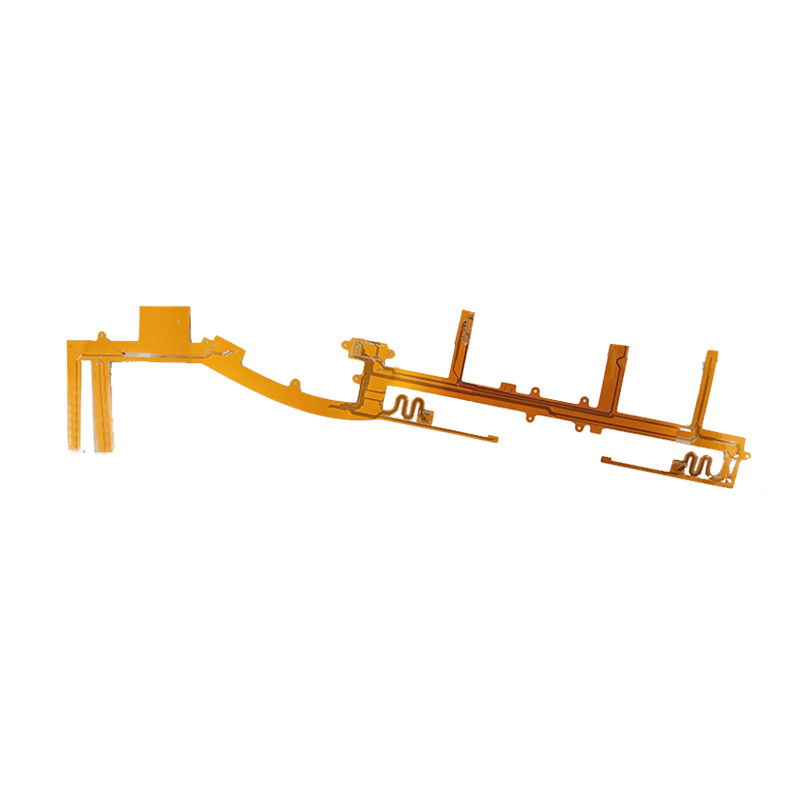

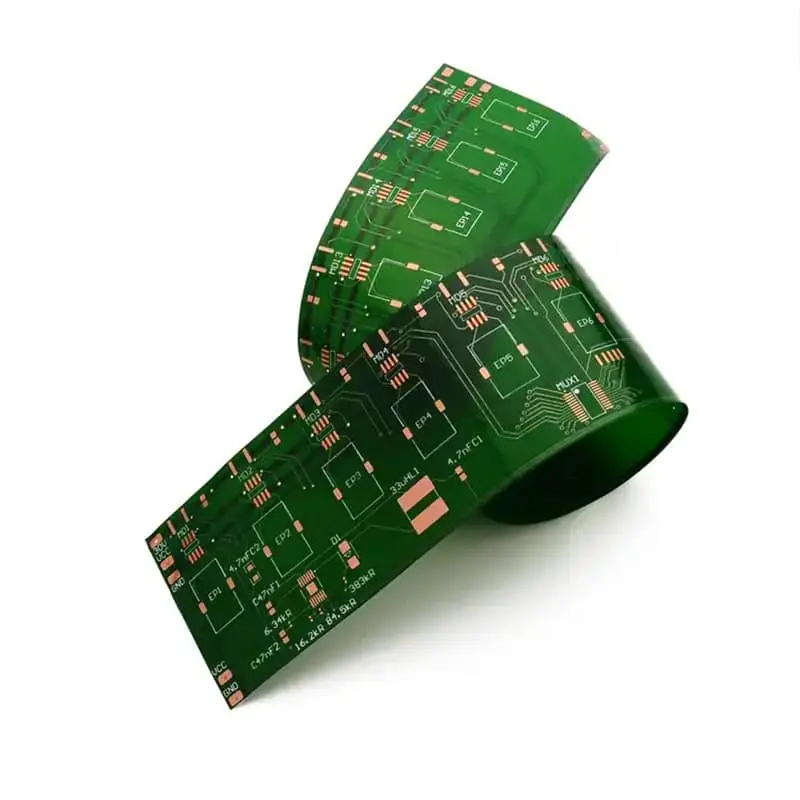

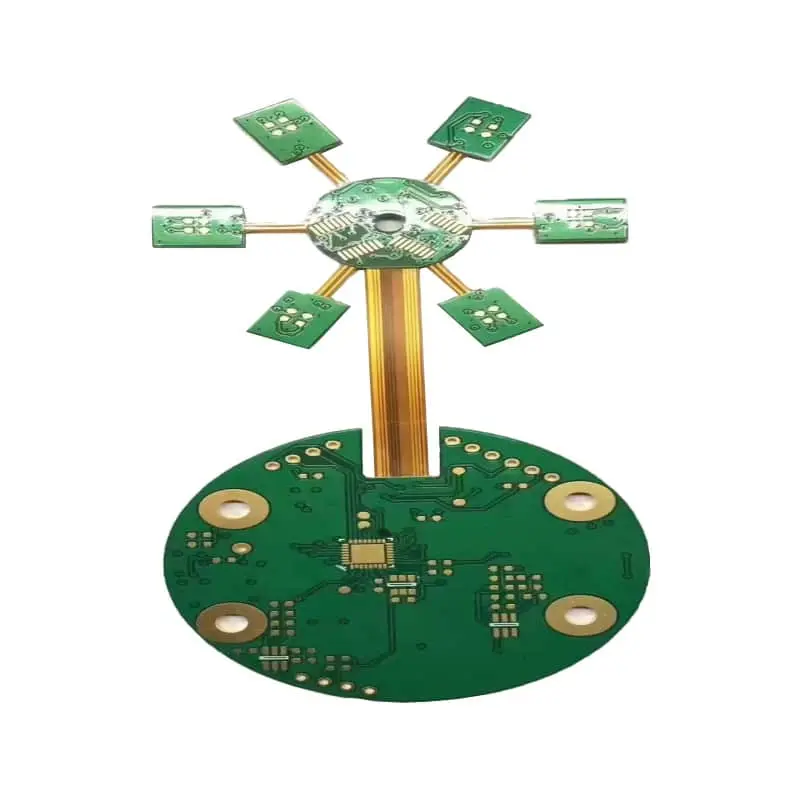

Flexible printed circuits (FPC) are widely used in various electronic devices due to their flexibility, lightweight nature, and ability to fit into compact spaces. Flexible printed circuits offer numerous advantages over traditional rigid PCBs, making them ideal for applications in wearable technology, medical devices, and more. However, soldering flexible printed circuits requires special techniques and considerations to ensure a reliable connection. This article will guide you through the process of soldering flexible printed circuits, comparing their properties with other circuit boards, and discussing important considerations.

Flexible printed circuits (FPC) are widely used in various electronic devices due to their flexibility, lightweight nature, and ability to fit into compact spaces. Flexible printed circuits offer numerous advantages over traditional rigid PCBs, making them ideal for applications in wearable technology, medical devices, and more. However, soldering flexible printed circuits requires special techniques and considerations to ensure a reliable connection. This article will guide you through the process of soldering flexible printed circuits, comparing their properties with other circuit boards, and discussing important considerations.

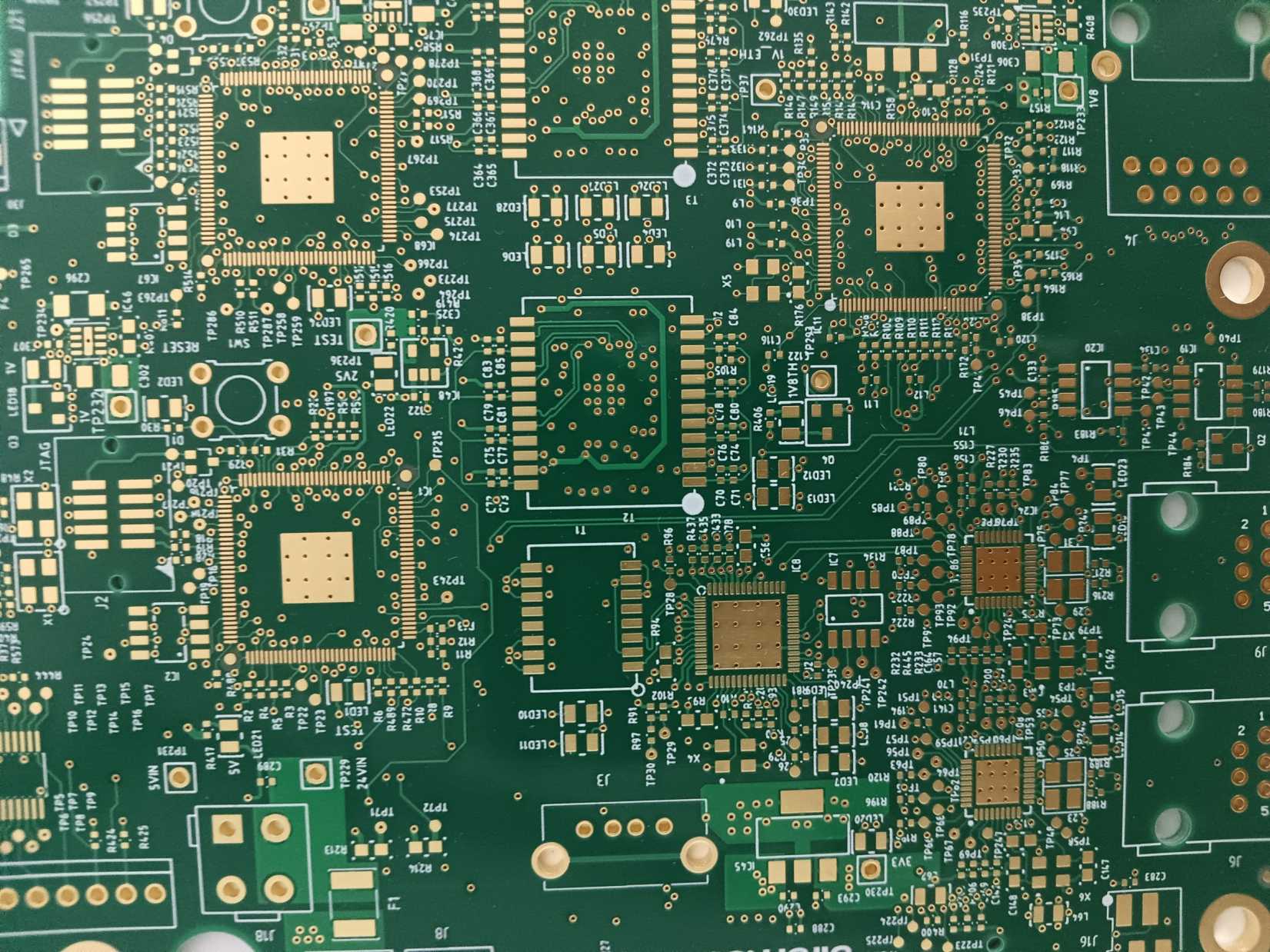

Characteristics of Flexible Printed Circuits

Flexible printed circuits stand out due to the unique properties that differentiate them from traditional rigid circuit boards:

- Flexibility: As the name suggests, flexible printed circuits can bend and twist, allowing them to fit into tight spaces and complex geometries. This flexibility is achieved through the use of thin, flexible substrates like polyimide or polyester.

- Lightweight and Thin: FPCs are significantly lighter and thinner than rigid PCBs, which makes them ideal for applications where weight and space are critical factors.

- Durability: Despite their flexibility, FPCs are durable and can withstand repeated bending and flexing without breaking.

- High Density: Flexible printed circuits can support high-density component placement, making them suitable for miniaturized electronic devices.

How to Solder Flexible Printed Circuits

Soldering flexible printed circuits involves a few specific steps to ensure a reliable and secure connection. Here’s a detailed guide on how to solder FPCs:

- Preparation: Before soldering, clean the flexible printed circuit to remove any contaminants that could affect the soldering process. Use isopropyl alcohol and a lint-free cloth to clean the surface.

- Tin the Pads: Apply a thin layer of solder (tinning) to the pads on the flexible printed circuit. This helps in achieving a good solder joint and reduces the risk of cold solder joints.

- Positioning: Carefully position the components on the FPC. Use tweezers to place the components accurately on the tinned pads.

- Soldering: Use a soldering iron with a fine tip and set the temperature to around 250-300°C. Apply a small amount of solder to the soldering iron tip and gently touch the component leads and pads. Ensure that the solder flows smoothly and creates a shiny, smooth joint.

- Inspection: After soldering, inspect the joints for any defects like cold solder joints, bridges, or insufficient solder. Use a magnifying glass or microscope to examine in detail.

- Cleaning: Clean the soldered areas with isopropyl alcohol to remove any flux residues. This prevents potential corrosion and ensures long-term reliability.

Considerations for Soldering Flexible Printed Circuits

When soldering flexible printed circuits, several factors need to be considered to achieve the best results:

- Temperature Control: Excessive heat can damage the flexible substrate. Ensure that the soldering iron temperature is appropriately set and that the soldering process is quick to avoid prolonged heat exposure.

- Support and Fixturing: Use a support jig or fixture to hold the FPC flat during soldering. This prevents movement and ensures the precise positioning of components.

- Type of Solder: Use solder with a low melting point, such as lead-free solder with a high tin content, to reduce the risk of thermal damage to the flexible circuit.

- Flexibility Management: After soldering, avoid bending the FPC near the solder joints to prevent stress and potential damage to the connections.

Conclusion

In conclusion, flexible printed circuits offer several advantages over traditional rigid PCBs, including flexibility, lightweight, and high-density component placement. Soldering flexible printed circuits requires specific techniques and careful considerations to ensure reliable connections. By following the proper preparation, soldering, and inspection steps, and by managing temperature and support effectively, you can achieve high-quality solder joints on flexible printed circuits. Whether for wearable technology, medical devices, or other applications, understanding how to solder flexible printed circuits is essential for modern electronics manufacturing.