Metal Core PCB (MCPCB)

Metal core printed circuit board (MCPCB), also known as thermally conductive PCB, is based on metal materials compared to conventional FR4 for the heat sink fragment of the board.During board operation, heat is generated due to certain electronic components. The purpose of metal is to transfer heat from critical board components to secondary areas, such as metal heatsink backings or metal cores. As a result, these PCBs are easy to thermally manage.

Share to:

| Key attributes |

| Industry-specific attributes |

| Base Material:96% Al2O3 |

| Board Thickness:0.5mm |

| Other attributes |

| Type: Metal Core PCB (MCPCB) |

| Copper Thickness:10-20um |

| Min. Hole Size:0.10mm |

| Min. Line Width:0.15mm |

| Min. Line Spacing:0.15mm |

| Surface Finishing: Silver Palladium conductor |

| Application: Laser Machine |

| Layer:1-32 Layers |

| Certificate:ISO9001/ISO16949/UL/RoHS |

| Packaging and delivery |

| Package Type: 1. at buyer’s request 2. inner, vacuum package 3. outer, standard export carton. |

| attribute-list |

| Supply Ability:500000 Square Centimeter/Square Centimeters per Month PCB Factory |

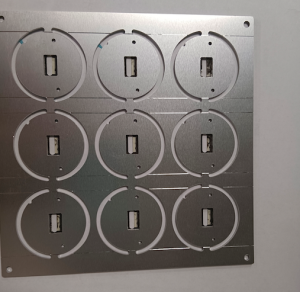

Metal Core Printed Circuit Boards for Power Electronics

Our metal core PCB (MCPCB) is designed to be used for excellent heat dissipation. It has high-power requirements as well as thermally sensitive applications, including LED lighting, automotive systems, and power electronics in particular. These metal core printed circuit board solutions consist of a metal base layer, typically containing aluminum, copper, or steel alloy, and provide superior thermal conductivity than regular PCBs for properly handling heat produced by electronic devices. This elegant design breaks the thermal barrier that high-power components produce heat, so when used in electronic parts, your electronics will be more reliable and last longer.

Metal Core PCB Construction

With up to 32 layers, our metal core PCB is designed to support complex circuits while maintaining exceptional thermal performance. The copper thickness ranges from 10 to 20µm, ensuring strong electrical conductivity, while the board’s robust design makes it highly durable even in extreme environments. Additionally, the metal core printed circuit boards feature minimum hole sizes of 0.10mm and high-precision drilling, making them suitable for intricate designs without compromising on quality.

Compliance Certification

Our MCPCBs are manufactured under stringent quality standards, with certifications including ISO9001, ISO16949, UL, and RoHS compliance. These certifications reflect our commitment to delivering metal core printed circuit board that meets the highest industry standards for performance, safety, and environmental responsibility.

Main Advantages

1. The primary advantage of using a metal core PCB lies in its ability to manage and reduce heat buildup in electronic devices, which is critical for ensuring long-term reliability. Applications that benefit from this technology include high-brightness LEDs, which generate substantial heat during operation, automotive lighting systems, power converters, and industrial machinery. These applications demand both high performance and durability, which our metal core printed circuit board delivers consistently.

2. In addition to superior heat dissipation, our MCPCBs offer excellent mechanical strength, making them resistant to physical damage and well-suited for harsh industrial environments. The metal base not only serves as a thermal conductor but also adds rigidity to the board, making it a reliable solution for high-stress applications.

3. Our MCPCBs also offer flexibility in design, allowing engineers to create intricate layouts that meet specific performance demands. The wide range of applications extends beyond lighting and automotive; they are also highly effective in renewable energy technologies, telecommunications, and military-grade equipment, where both thermal and mechanical stability are crucial. This versatility ensures our metal core PCBs will continue to support emerging industries with their need for high-power, heat-sensitive electronics.

Overall, our metal core PCB solutions are designed to meet the growing demand for advanced thermal management in modern electronics. Whether you’re looking to enhance the efficiency of high-power lighting or ensure the longevity of critical industrial electronics, our metal core printed circuit board provides the perfect balance of performance, durability, and cost-effectiveness.

For more information about our products and detailed specifications, feel free to contact us. We’re happy to assist with custom solutions tailored to your exact needs.