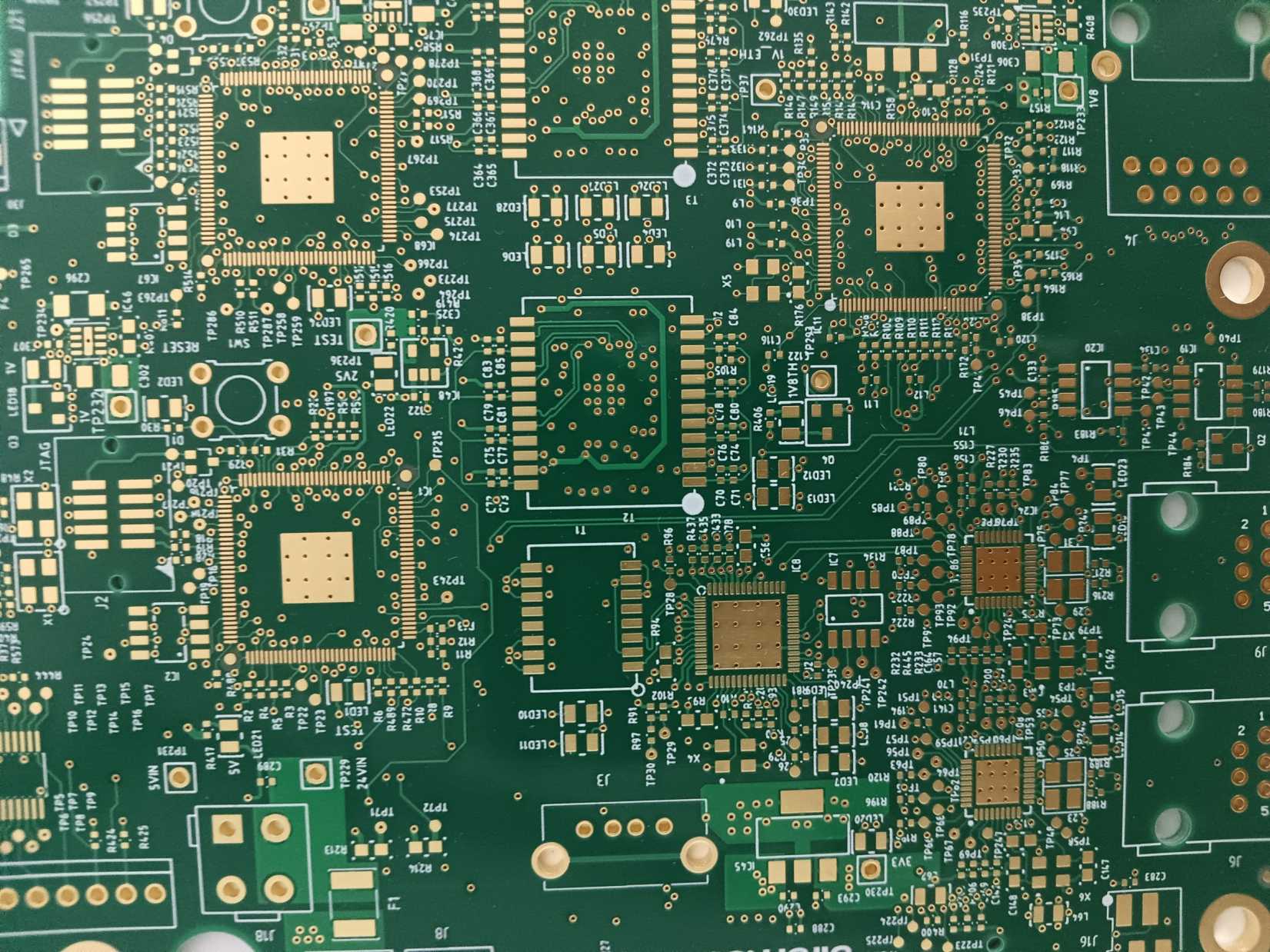

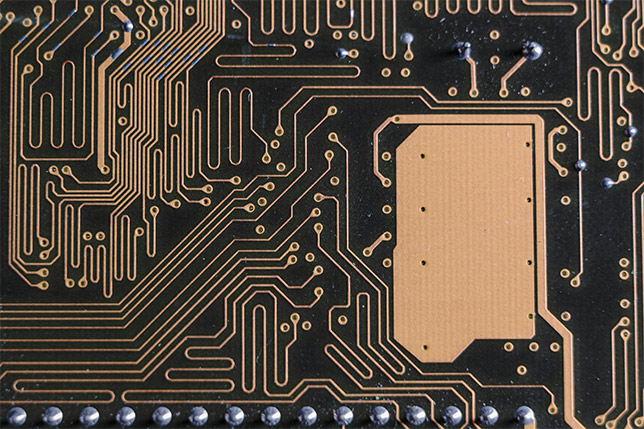

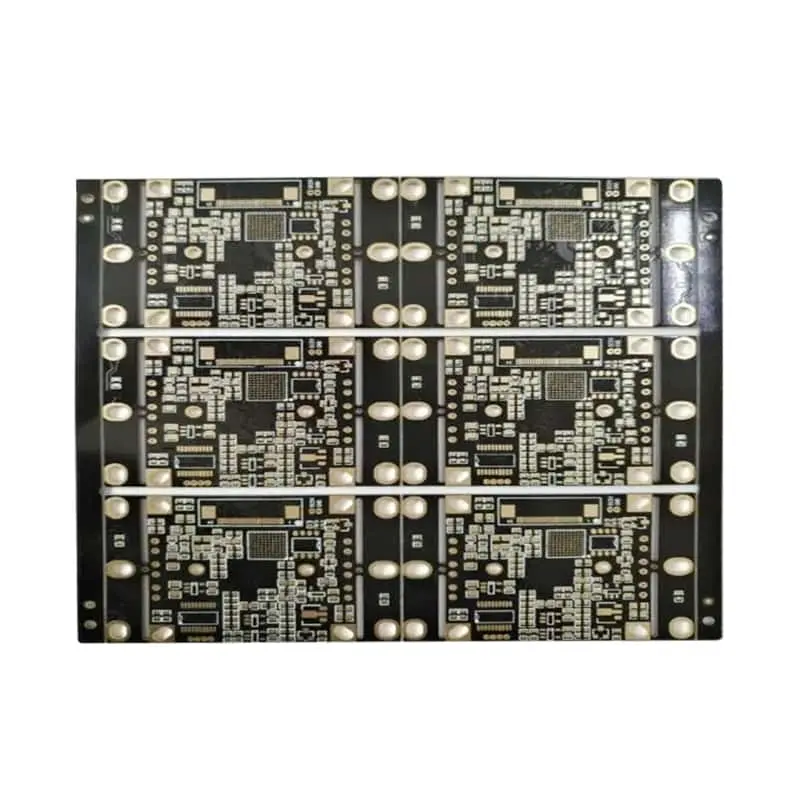

Soldering is a fundamental skill in electronics assembly, playing a critical role in creating reliable electrical connections between components and the printed circuit board (PCB). The importance of soldering extends beyond mere connectivity; it ensures the durability and performance of the electronic device. There are two primary techniques used in soldering components onto PCBs: Through-Hole Soldering and Surface-Mount Soldering.

Techniques for Soldering Components on PCB

Through-Hole Soldering

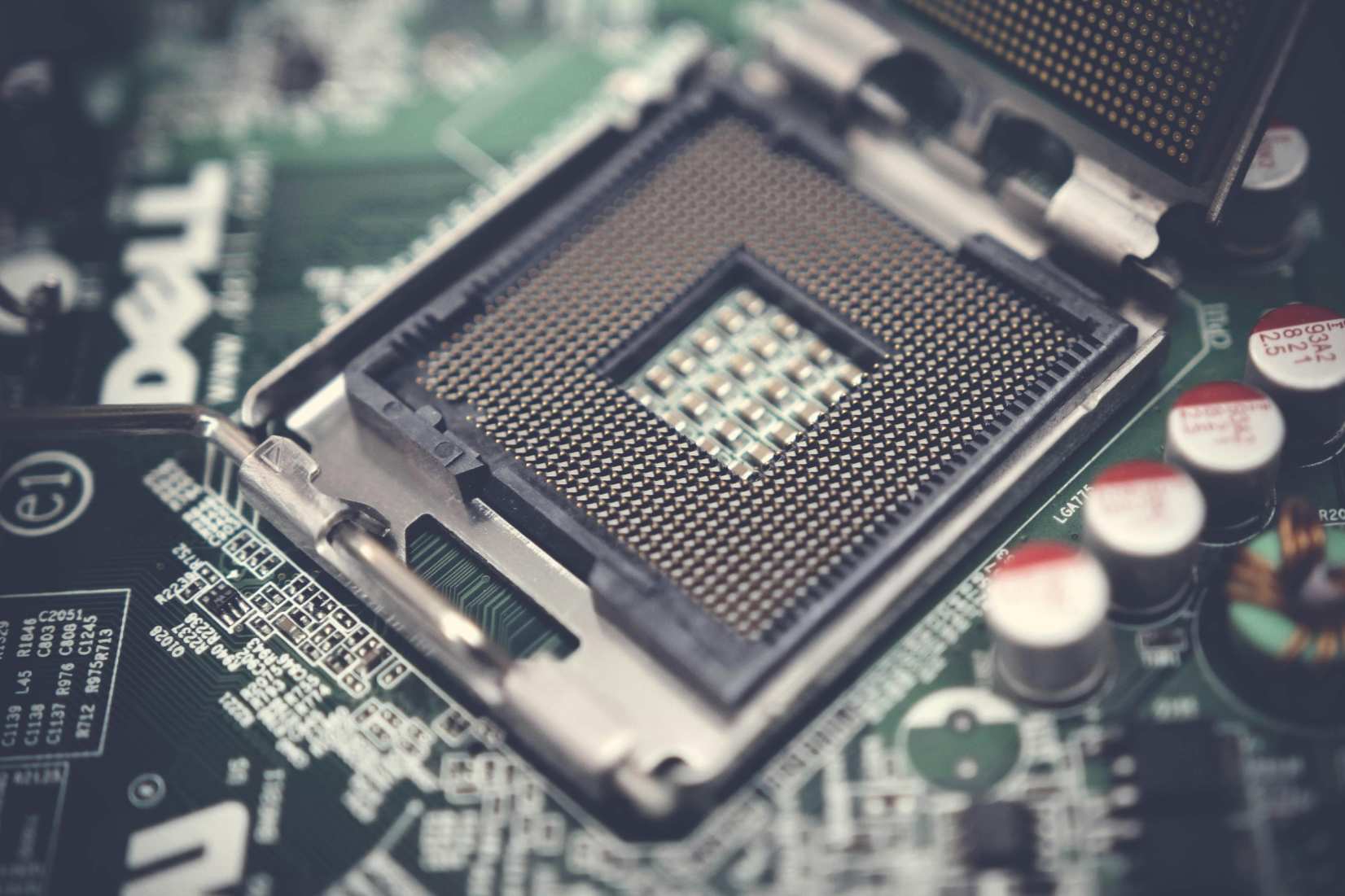

Through-hole soldering involves inserting component leads through holes drilled into the PCB and then soldering them on the opposite side to secure the component in place. This traditional method is often used for components that require strong mechanical bonds, such as connectors and large capacitors.

Advantages:

– Strong mechanical connection

– Easier inspection and testing

Disadvantages:

– More complex and time-consuming assembly

– Requires larger PCB space

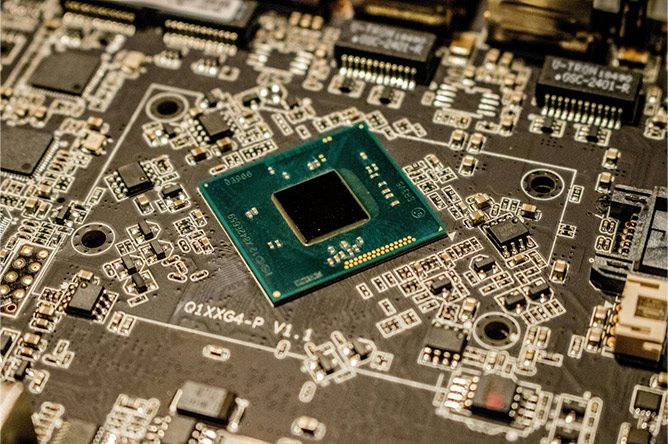

Surface-Mount Soldering

Surface-mount soldering, on the other hand, involves placing components directly onto the surface of the PCB, where solder paste holds them in place before heating to form a permanent bond. This method is prevalent in modern electronics due to its efficiency and the smaller component sizes it allows.

Advantages:

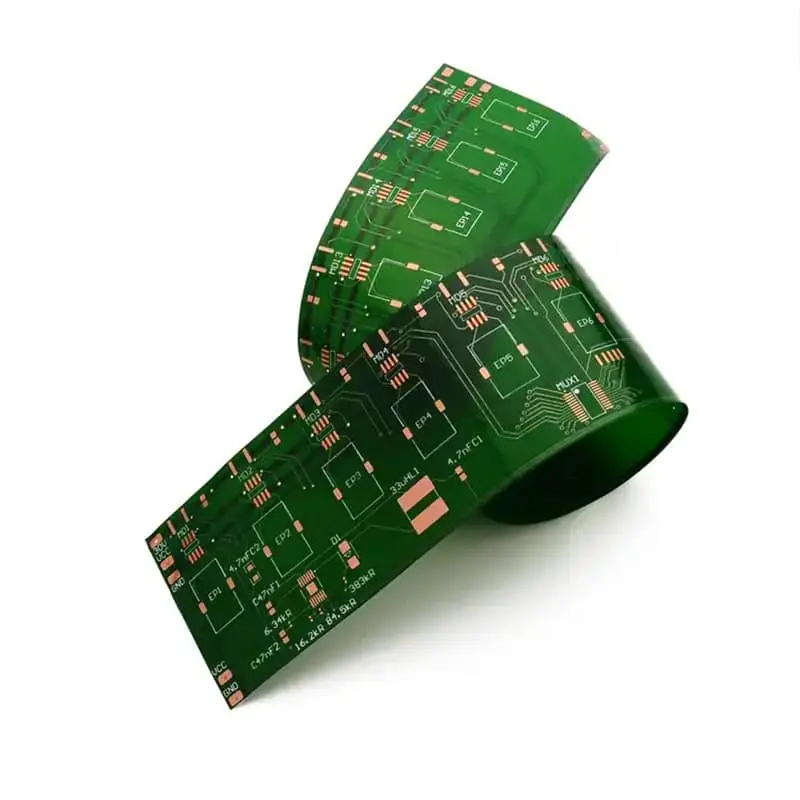

– Space-efficient, allowing for smaller PCBs

– Faster and more cost-effective for mass production

Disadvantages:

– Less mechanical strength compared to through-hole

– More challenging to inspect and repair

Comparative Analysis of Soldering Techniques

When comparing through-hole and surface-mount soldering, several factors come into play:

When comparing through-hole and surface-mount soldering, several factors come into play:

Efficiency and Application: Surface-mount soldering is generally more efficient for high-volume production due to its automation capabilities. In contrast, through-hole soldering is preferred for components that need to withstand mechanical stress.

Cost Implications: Surface-mount technology (SMT) can be more cost-effective for large-scale manufacturing because it requires less manual labor and can be automated. However, the initial setup cost for SMT can be higher due to the need for specialized equipment.

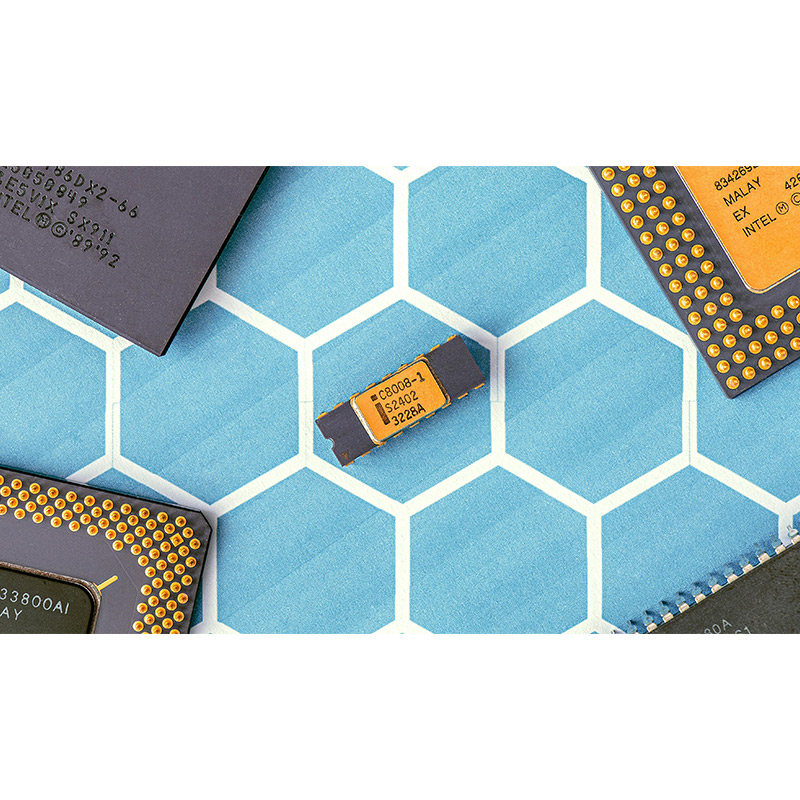

Suitability for Different Types of Projects: Through-hole soldering is suitable for prototypes, hobby projects, and applications where mechanical strength is crucial. SMT is ideal for compact, high-density circuits in consumer electronics, such as smartphones and laptops.

Best Practices and Tips for Effective Soldering

To achieve high-quality solder joints, consider the following best practices:

Tools and Materials Needed:

– Soldering iron with adjustable temperature control

– Quality solder (preferably lead-free)

– Soldering flux to improve the flow of solder

Common Mistakes and How to Avoid Them:

– Cold Joints: Ensure the soldering iron is at the correct temperature and the components are heated evenly before applying solder.

– Excess Solder: Avoid using too much solder, which can create bridges between joints and cause short circuits.

– Poor Component Placement: Use tweezers and magnification tools to position components accurately, especially for SMT.

Industry Insights and Recommendations:

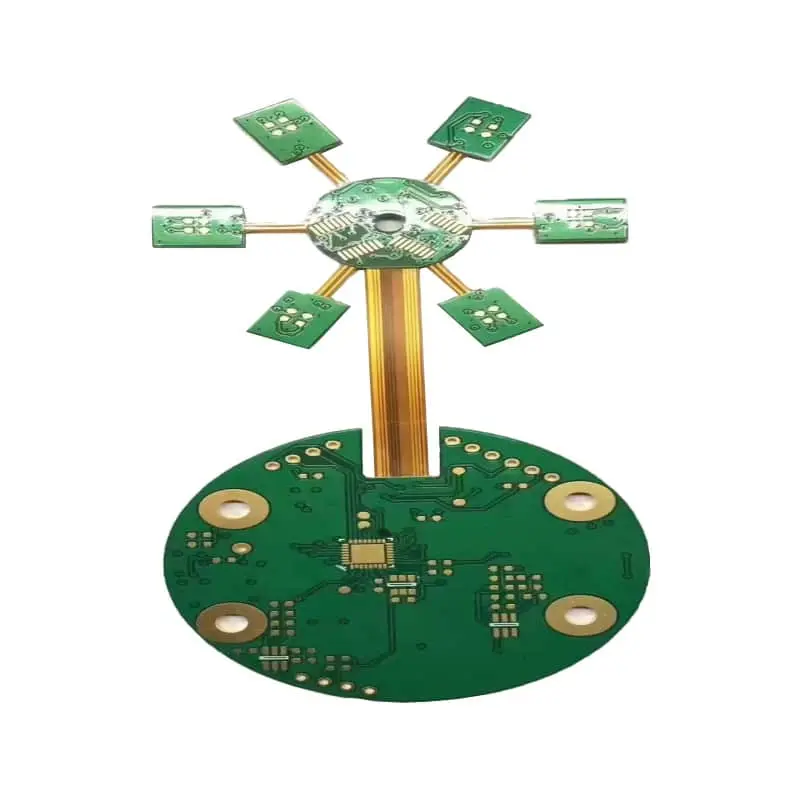

From an industry perspective, the choice between through-hole and surface-mount soldering often depends on the specific requirements of the project. For instance, in automotive and aerospace applications, the reliability and mechanical strength of through-hole soldering are preferred. However, in consumer electronics, the compactness and production efficiency of SMT make it the go-to method. Understanding the unique needs of each application ensures the optimal choice of soldering technique.

Conclusion

In summary, both through-hole and surface-mount soldering have their distinct advantages and challenges. Through-hole soldering offers robust mechanical connections and ease of inspection, making it suitable for certain applications. Surface-mount soldering, with its space-saving and efficient characteristics, is ideal for modern, high-density electronic assemblies. By understanding these techniques and following best practices, one can achieve reliable and high-performance solder joints, tailored to the specific needs of any electronic project.

If you have any questions or product needs, please contact PCBCOMING.