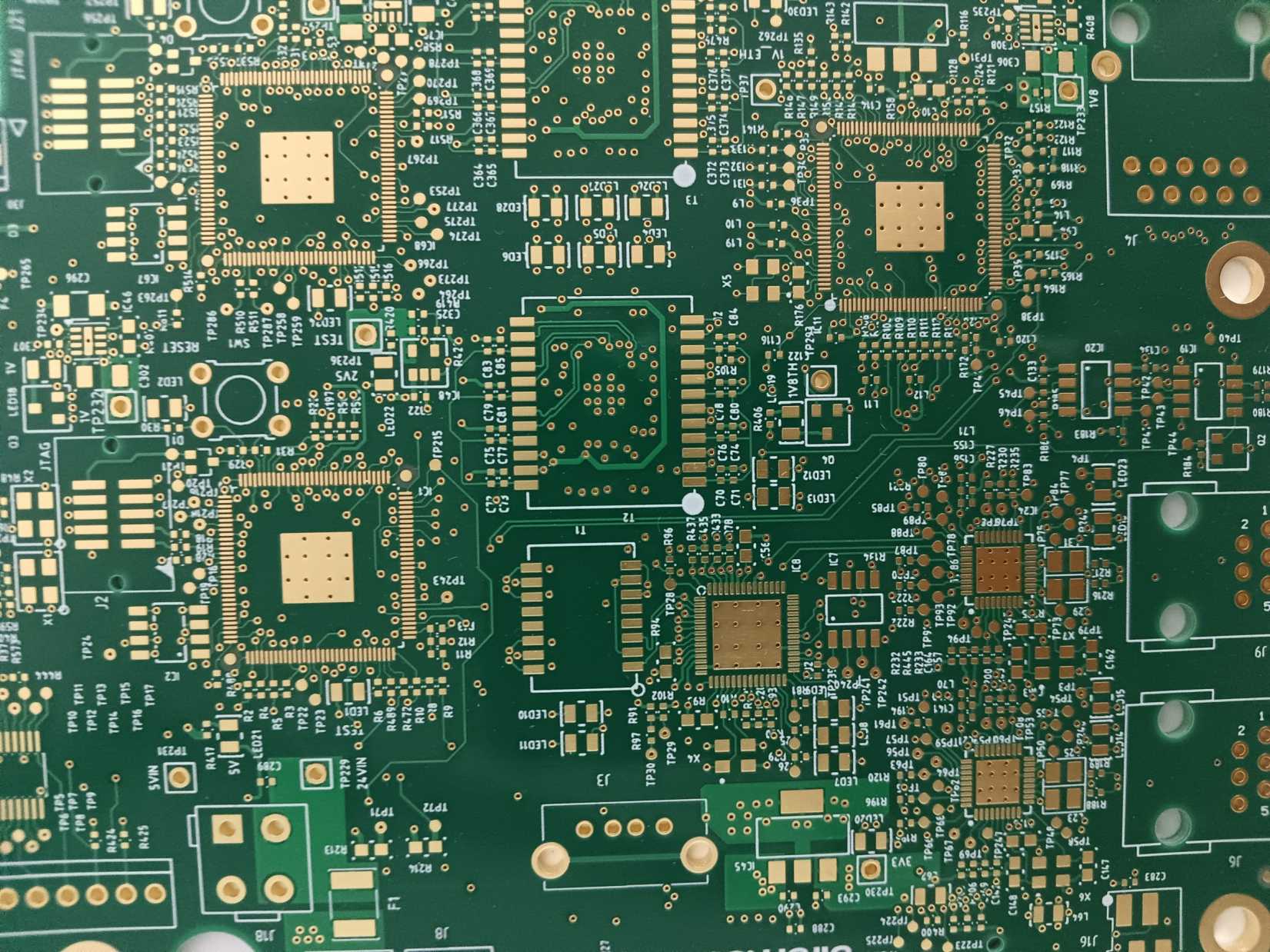

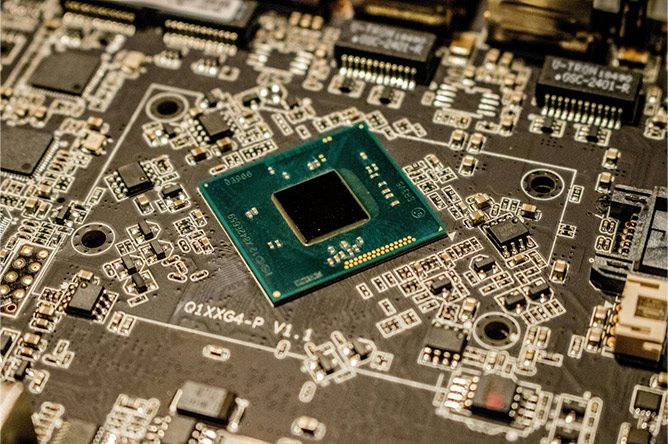

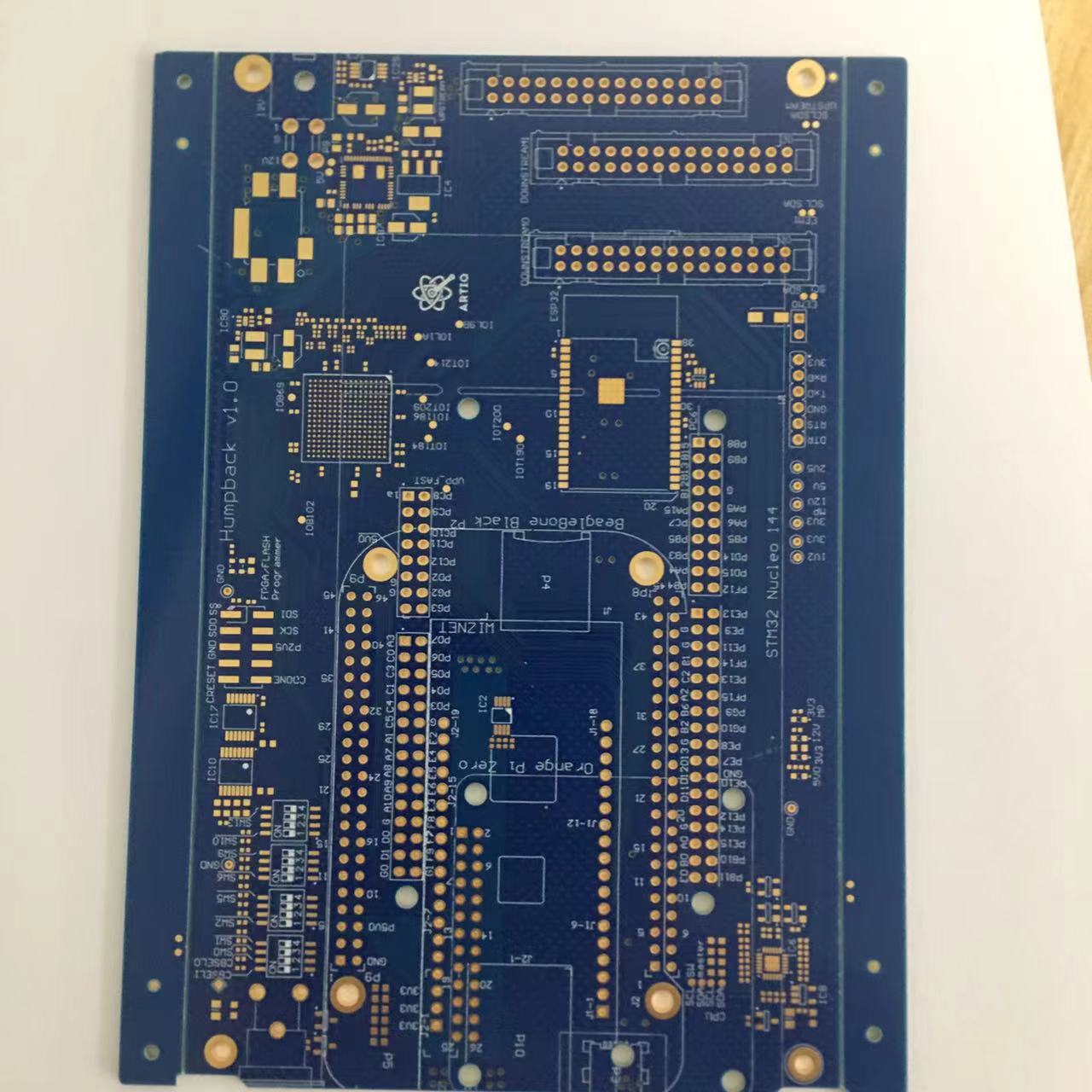

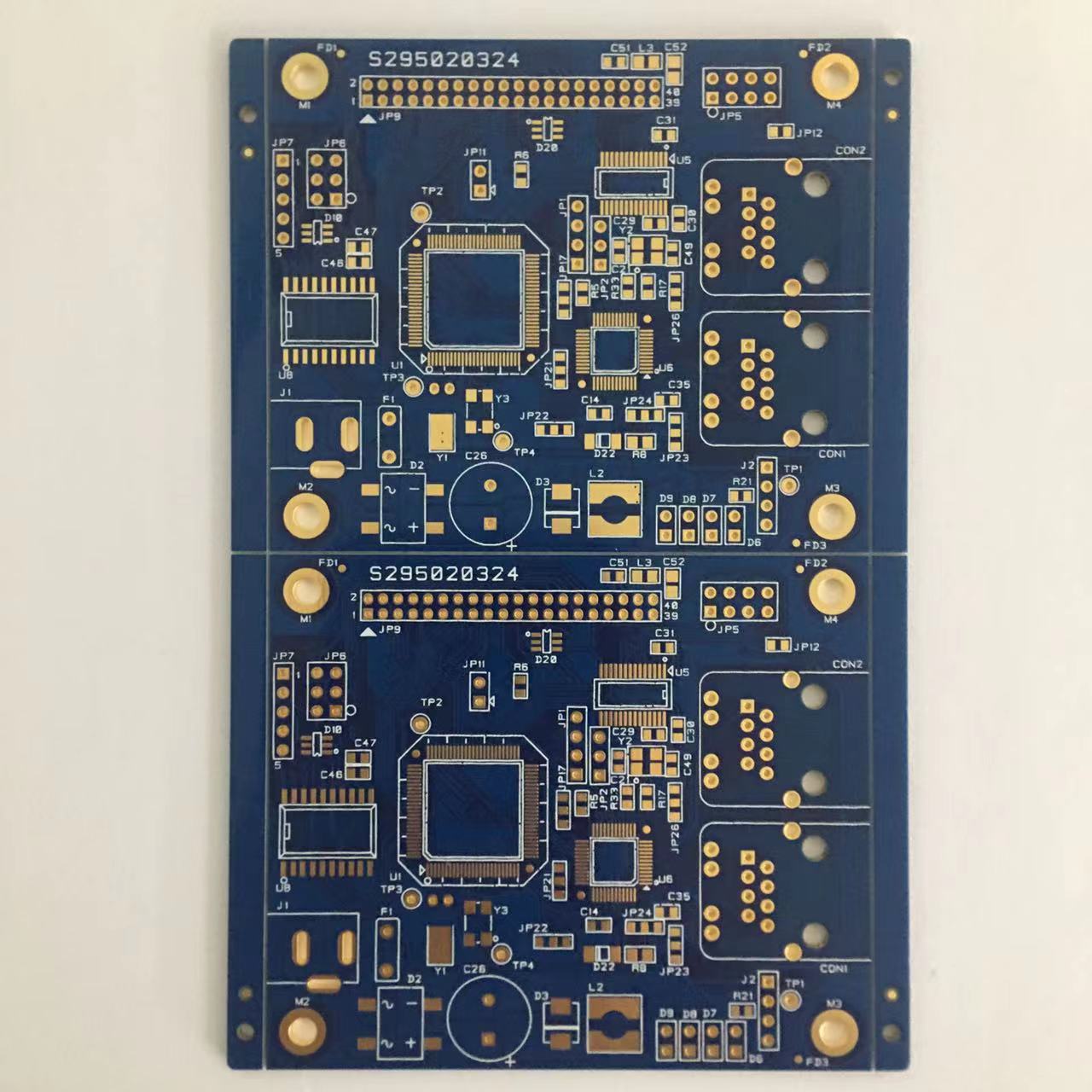

In today’s technological landscape, electronic devices are expected to perform flawlessly even in the most challenging environments. From industrial machinery exposed to extreme temperatures to outdoor electronic signage enduring harsh weather conditions, the reliability and performance of printed circuit boards, mean PCBs for harsh environments play a crucial role.

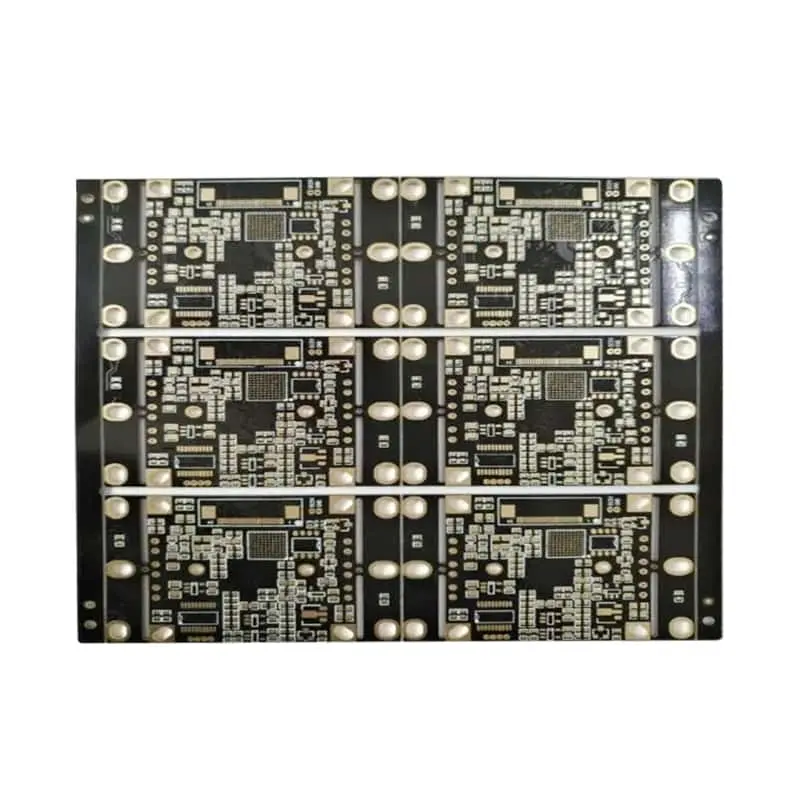

PCBCOMING, PCBs for Harsh Environments Leader In Service

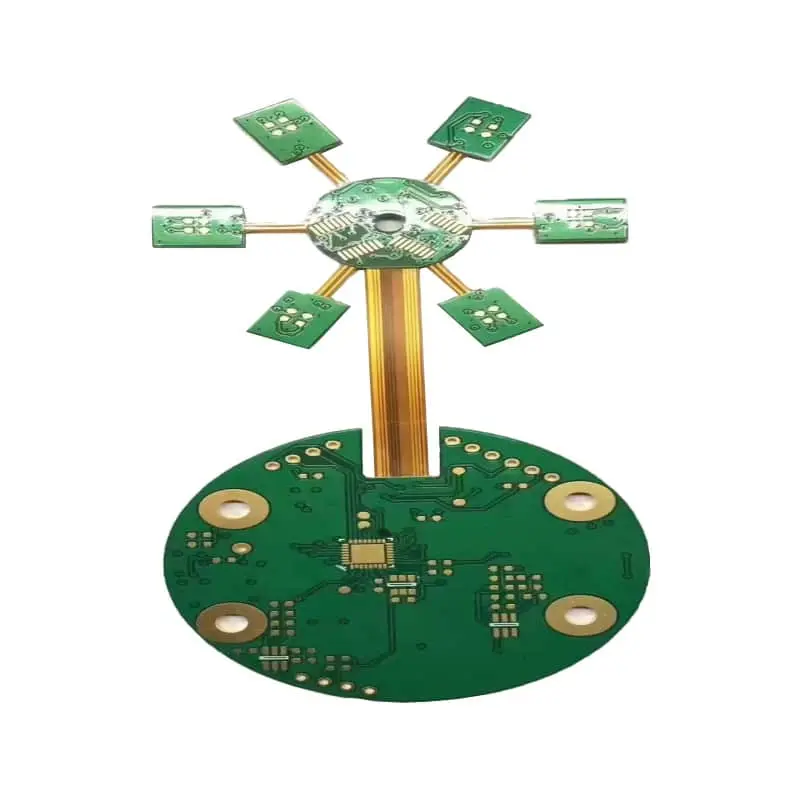

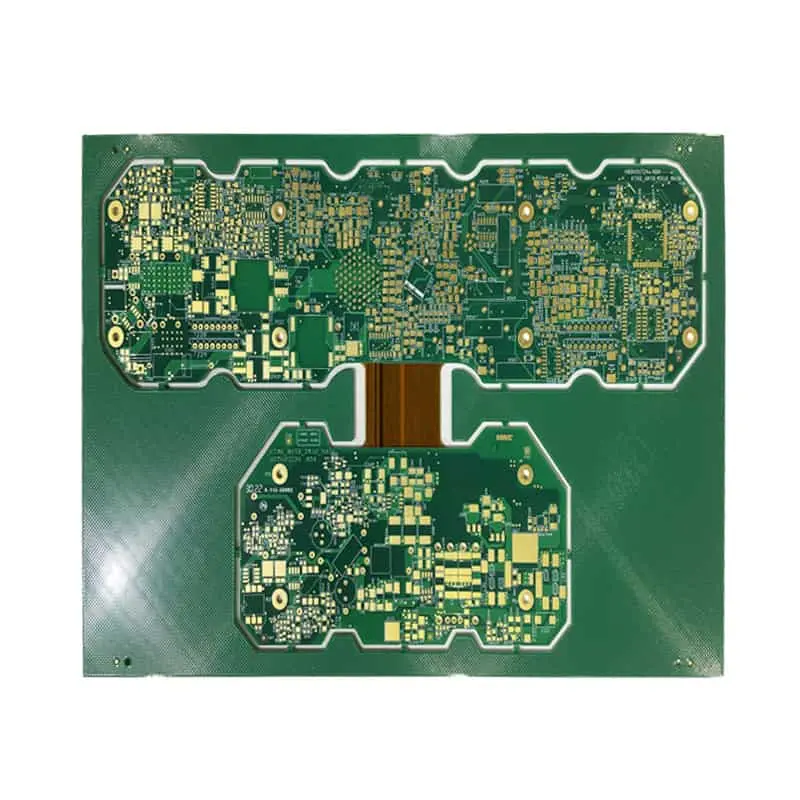

understands the importance of designing and manufacturing PCBs that can withstand these demanding conditions. PCBCOMING’s dedication to engineering PCB solutions that excel in harsh environments is evident in its strategic design approach, meticulous material selection, and rigorous testing protocols.

Understanding Harsh environments encompasses a wide range of challenges, including temperature extremes, humidity, dust, vibration, and corrosive substances. Devices operating in such conditions require PCBs, that are not only durable but also optimized for performance under stress. PCBCOMING specializes in creating PCB solutions tailored to these specific requirements.

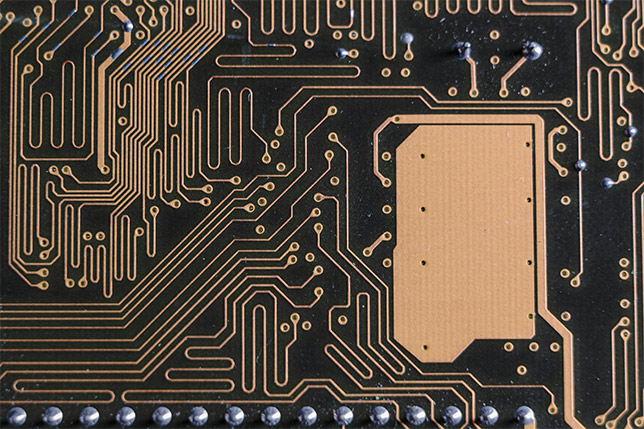

Design Considerations for Harsh Environments When designing PCBs for harsh environments, several key factors come into play:

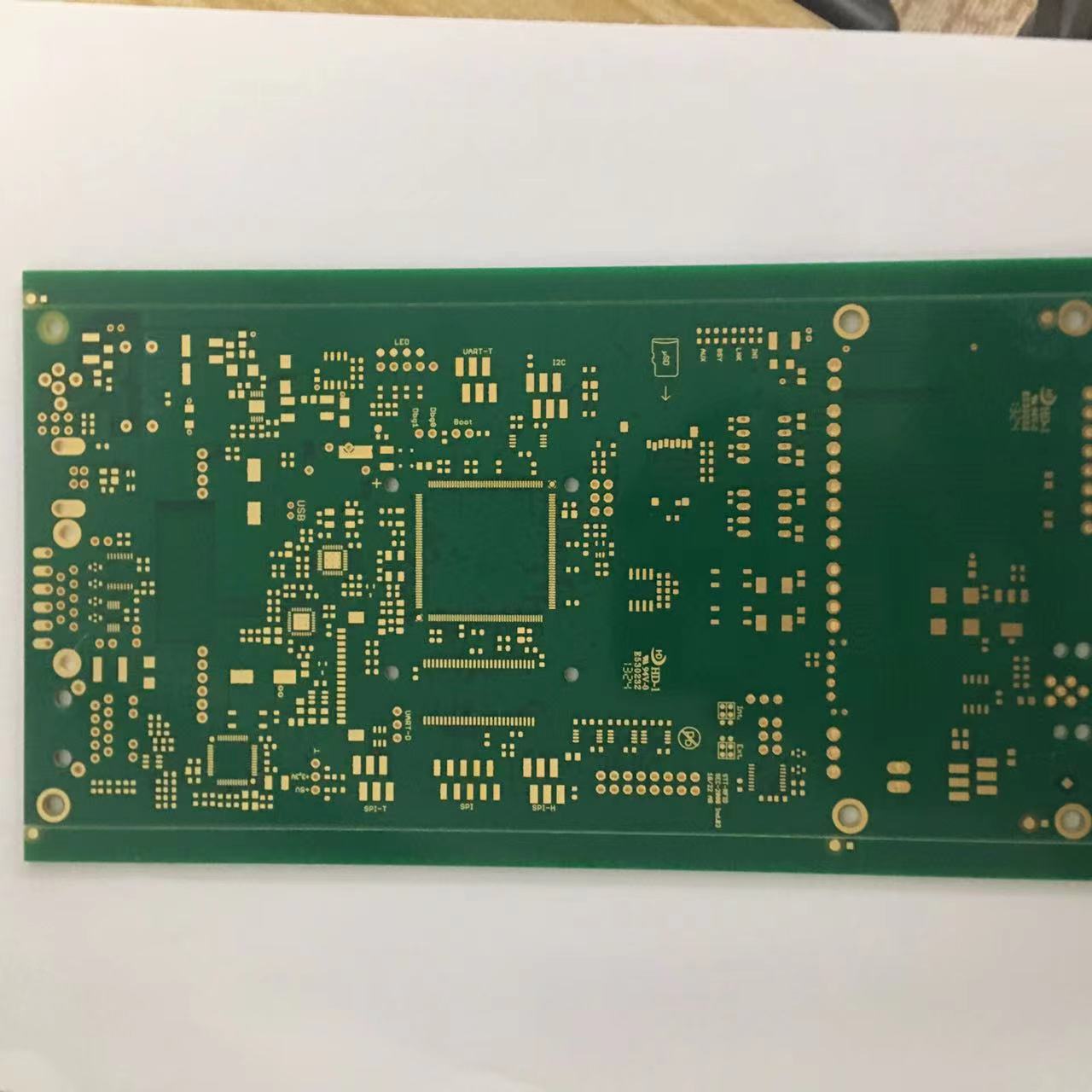

1. Material Selection:

PCBCOMING utilizes high-quality materials that are resistant to temperature fluctuations, moisture ingress, and chemical exposure. This ensures the longevity and reliability of the PCBs in challenging settings.

2. Component Placement:

Proper placement of components is critical to minimize the impact of vibrations and mechanical stress. PCBCOMING’s design experts optimize component layouts for maximum stability.

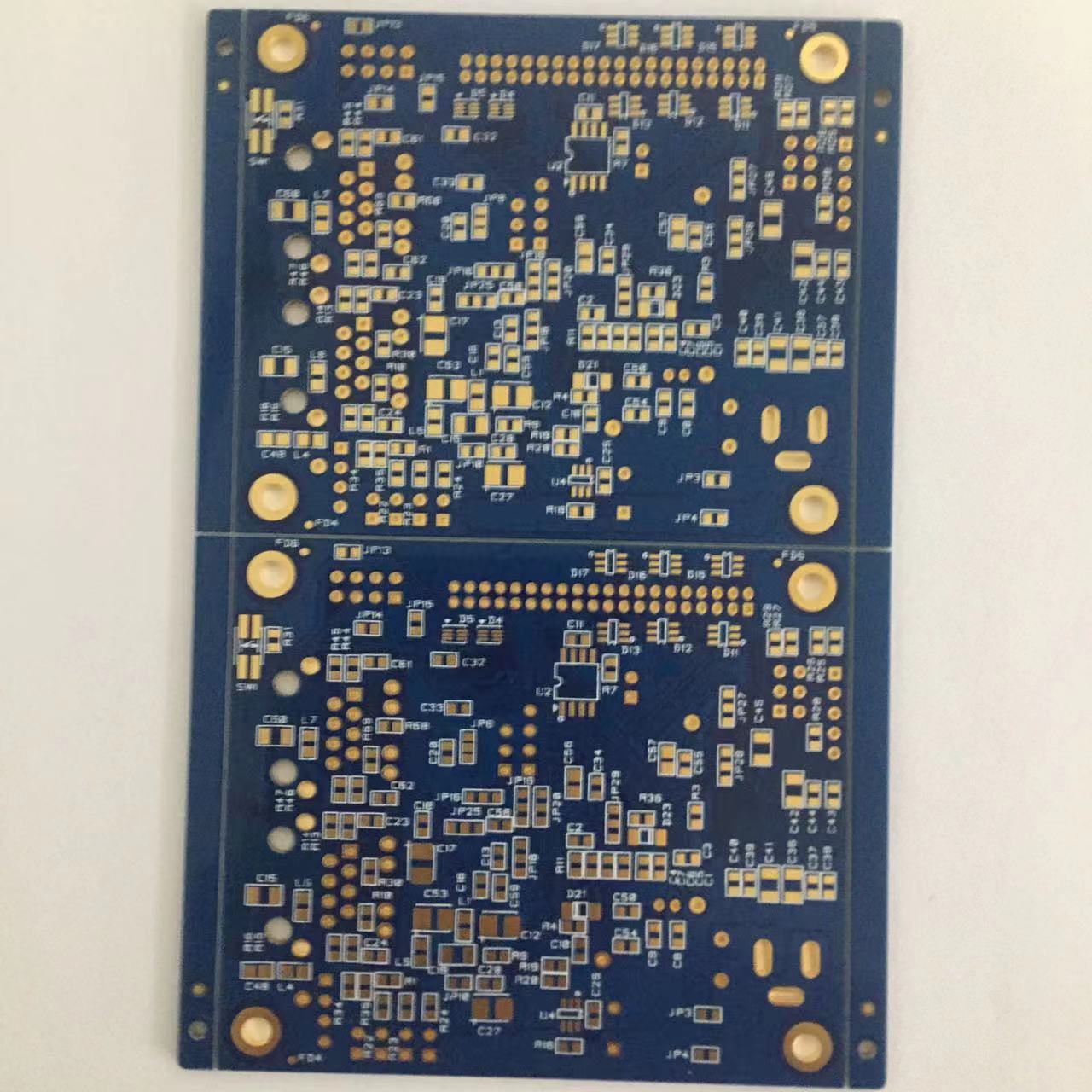

3.Coating and Encapsulation:

To further protect PCBs from harsh environments from environmental hazards, PCBCOMING offers advanced coating and encapsulation options. These techniques shield the circuitry from moisture, dust, and corrosive agents, extending the lifespan of the PCBs.

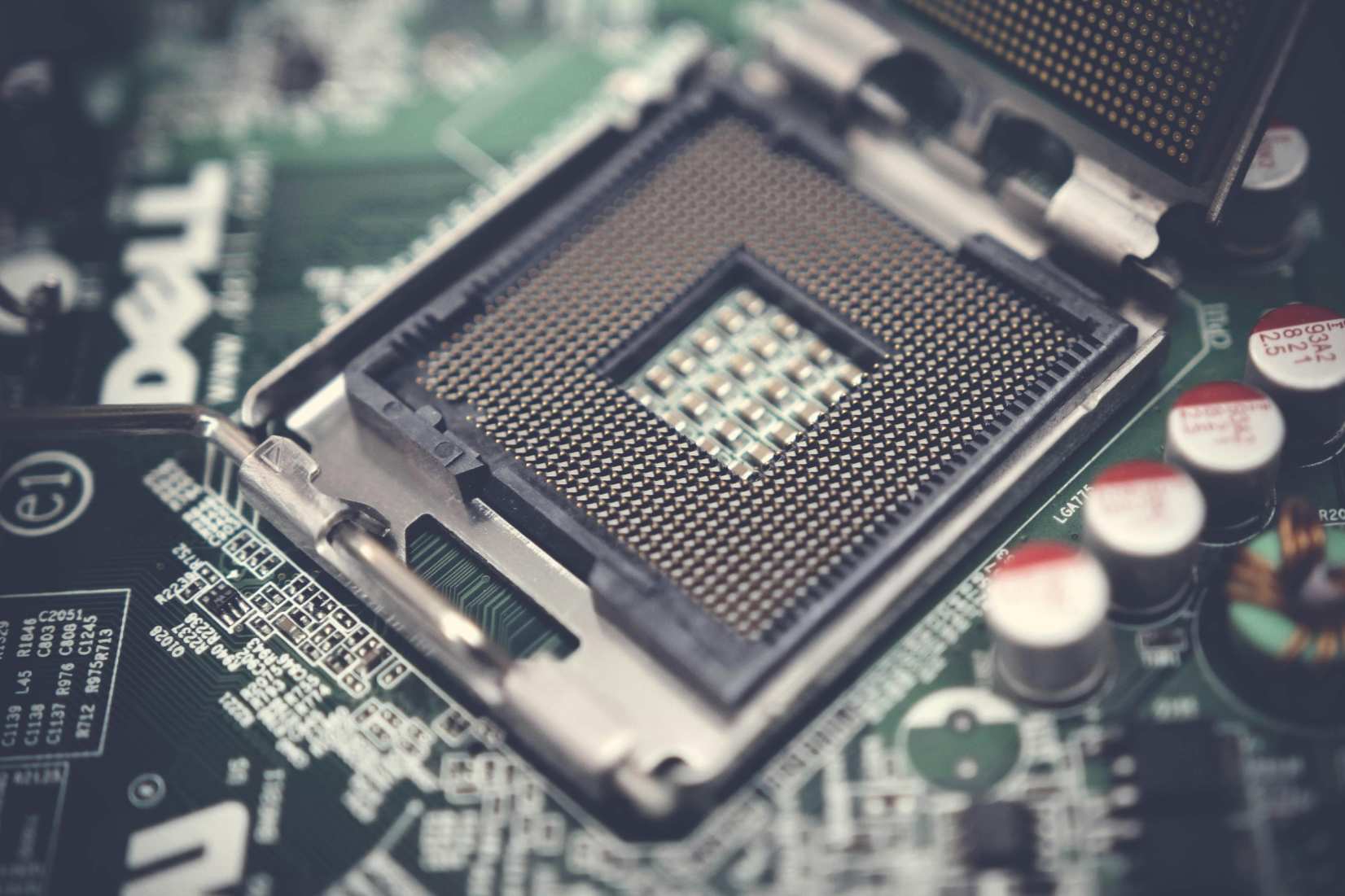

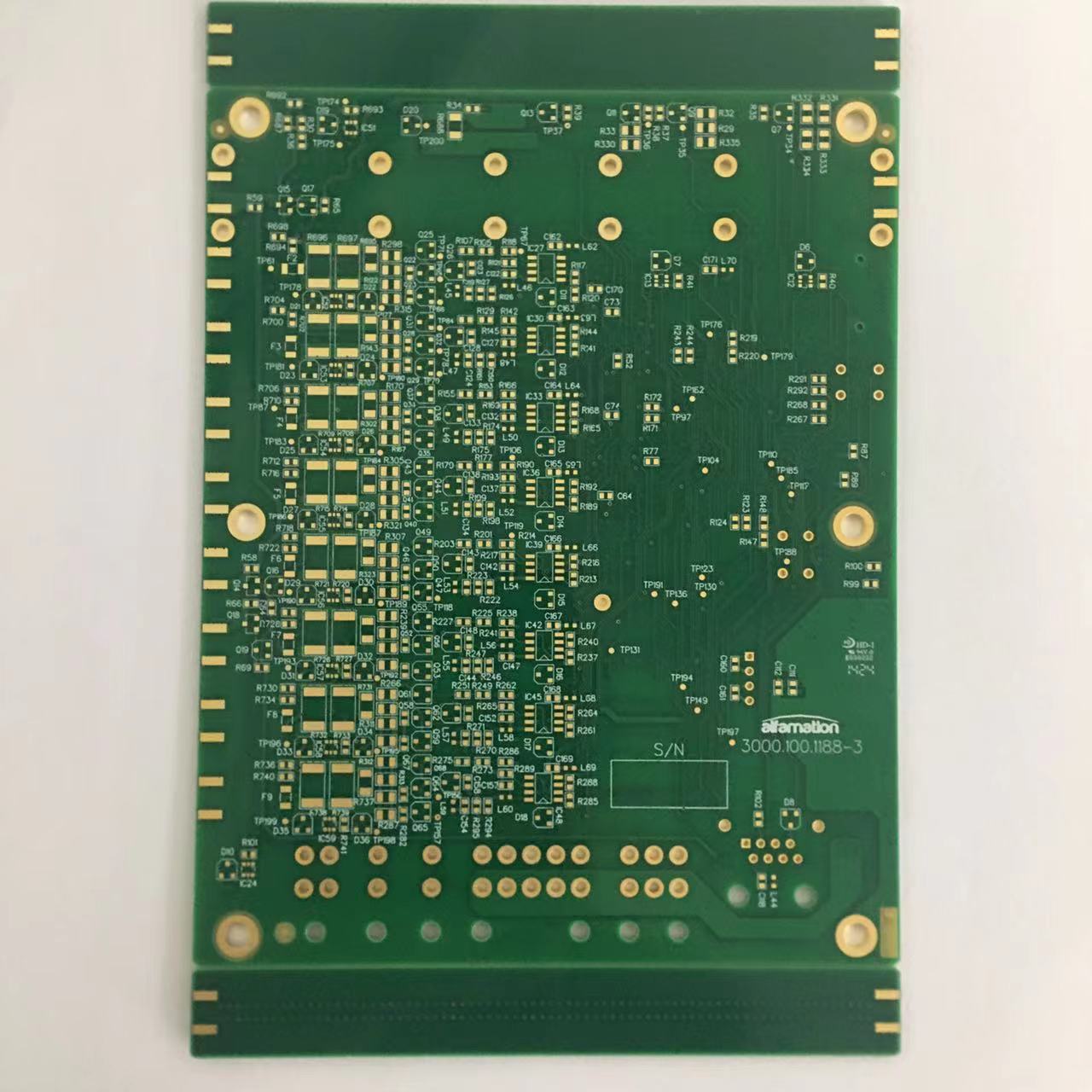

4. Testing and Quality Assurance:

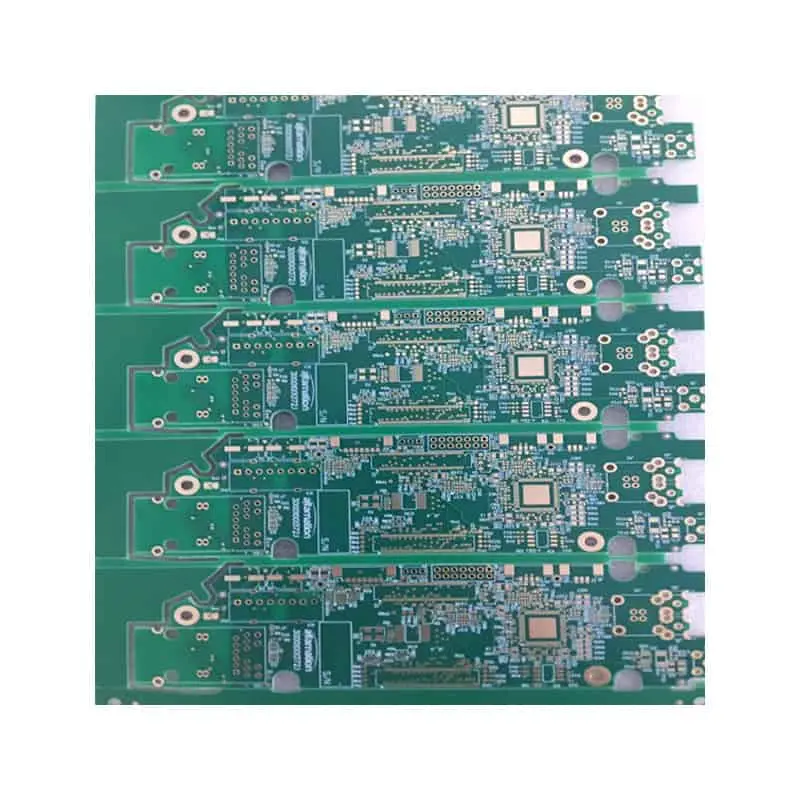

Before deployment, PCBs undergo rigorous testing to verify their performance under simulated harsh conditions. PCBCOMING’s quality assurance processes ensure that every PCB meets the highest standards of reliability and durability.

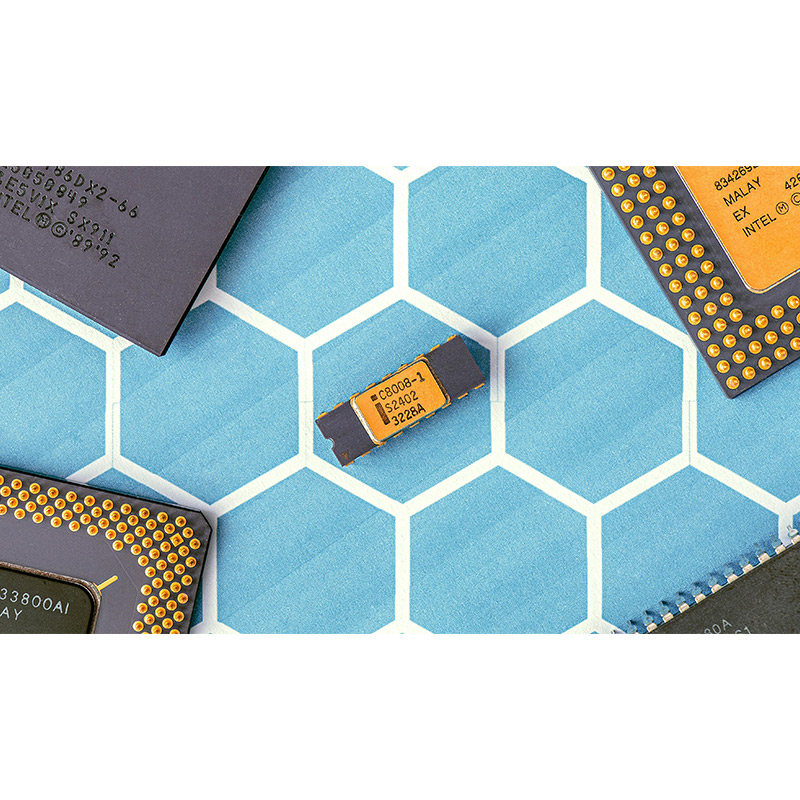

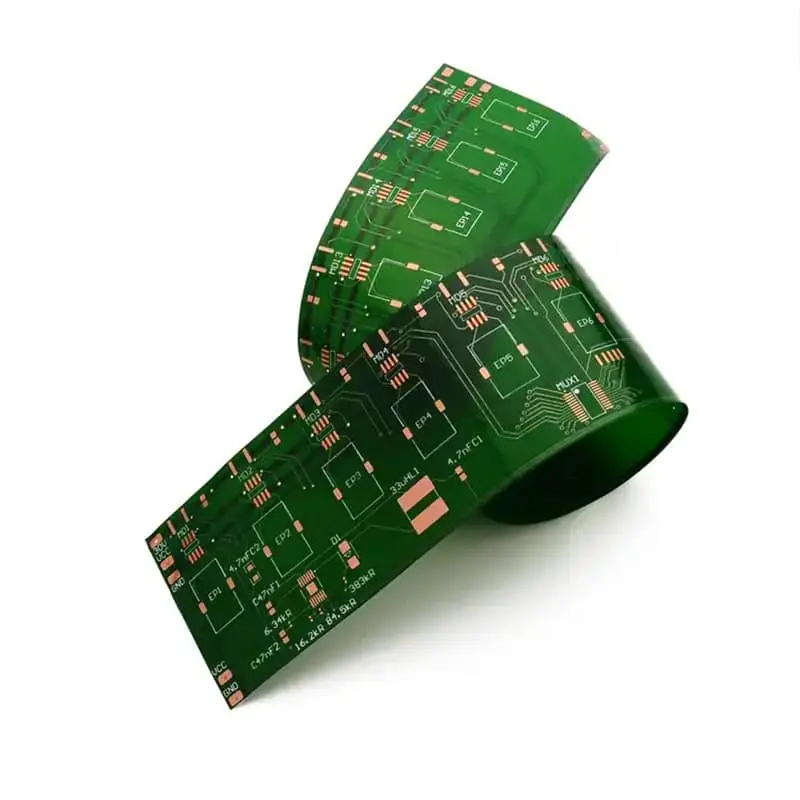

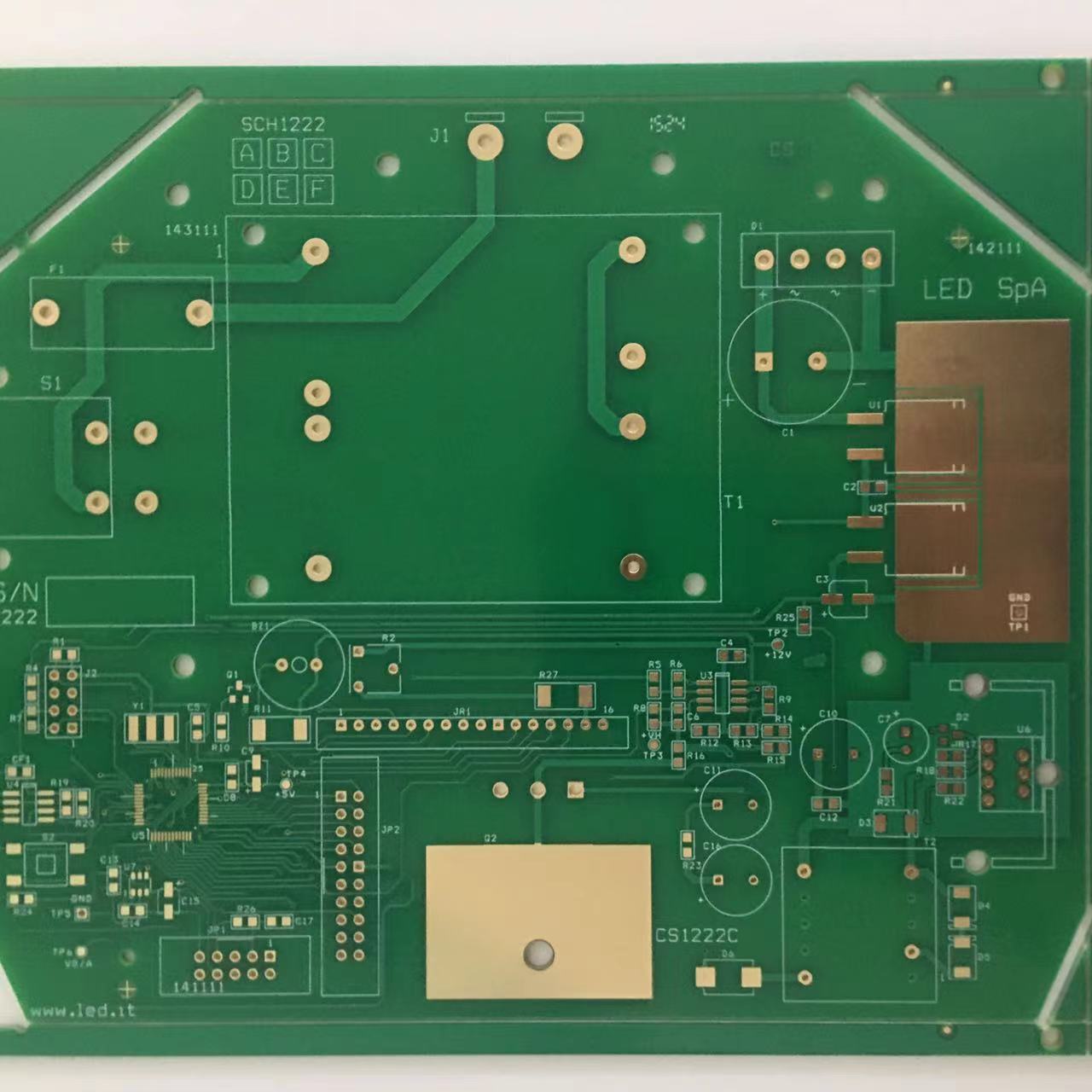

Applications in Various Industries PCBs for harsh environments find applications across diverse industries:

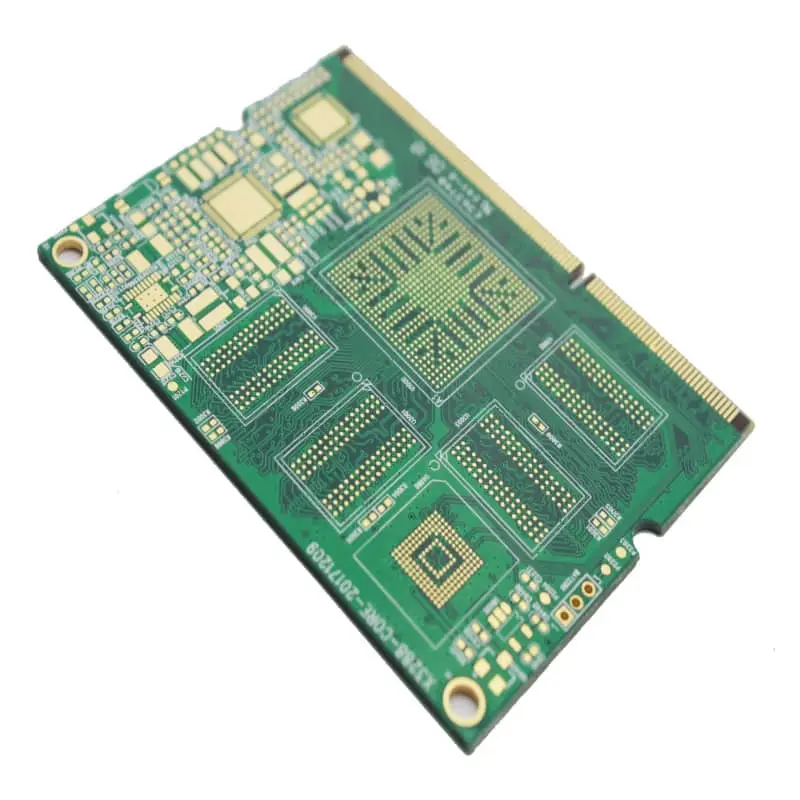

-Automotive: In vehicles, PCBs for harsh environments must endure temperature variations, vibrations, and exposure to fluids. Reliable PCBs are crucial for automotive electronics, including engine control units, infotainment systems, and sensors.

-Industrial Automation: Machinery and equipment used in industrial settings often face rugged conditions. Robust PCBs enable seamless automation and monitoring in factories and industrial plants.

-Aerospace and Defense: Aerospace applications demand PCBs that can withstand extreme temperatures, altitude changes, and electromagnetic interference. PCBCOMING’s expertise in aerospace-grade PCBs ensures mission-critical reliability.

-Outdoor Electronics: From outdoor displays to surveillance systems, outdoor electronics require PCBs with weatherproofing and UV resistance. PCBCOMING’s solutions ensure optimal performance in outdoor environments.

Conclusion

In the realm of electronics, reliability is non-negotiable, especially in harsh environments. PCBCOMING‘s commitment to quality, innovation, and customer satisfaction makes it the go-to partner for high-speed turnkey PCB services tailored to withstand the toughest conditions. Trust PCBCOMING to deliver PCB solutions that exceed expectations, ensuring your devices perform flawlessly even in the harshest of environments. In conclusion, PCBCOMING continues to lead the industry in providing reliable and durable PCBs, that power innovation across various sectors.