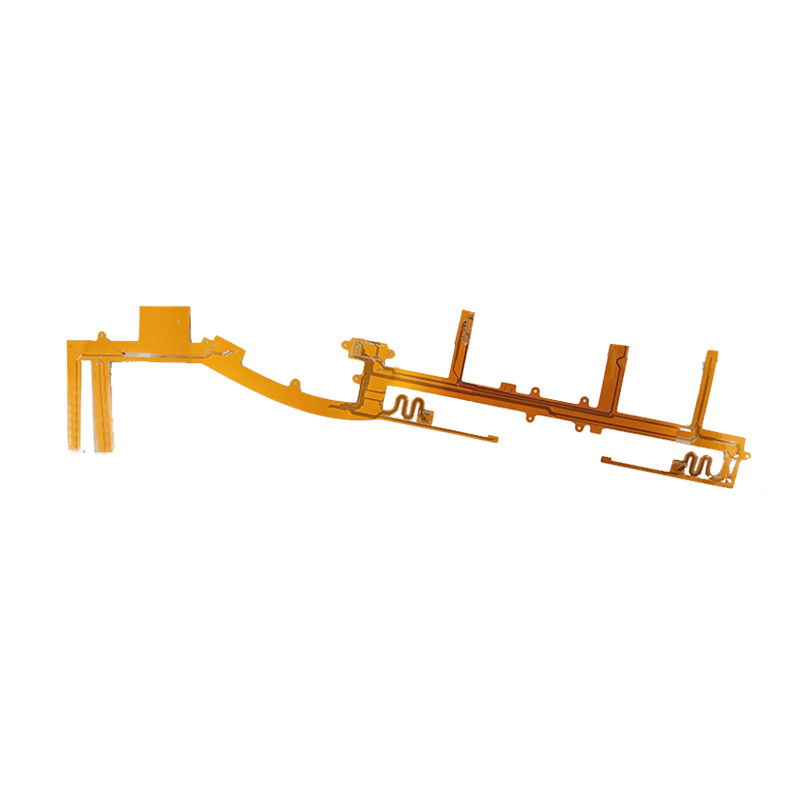

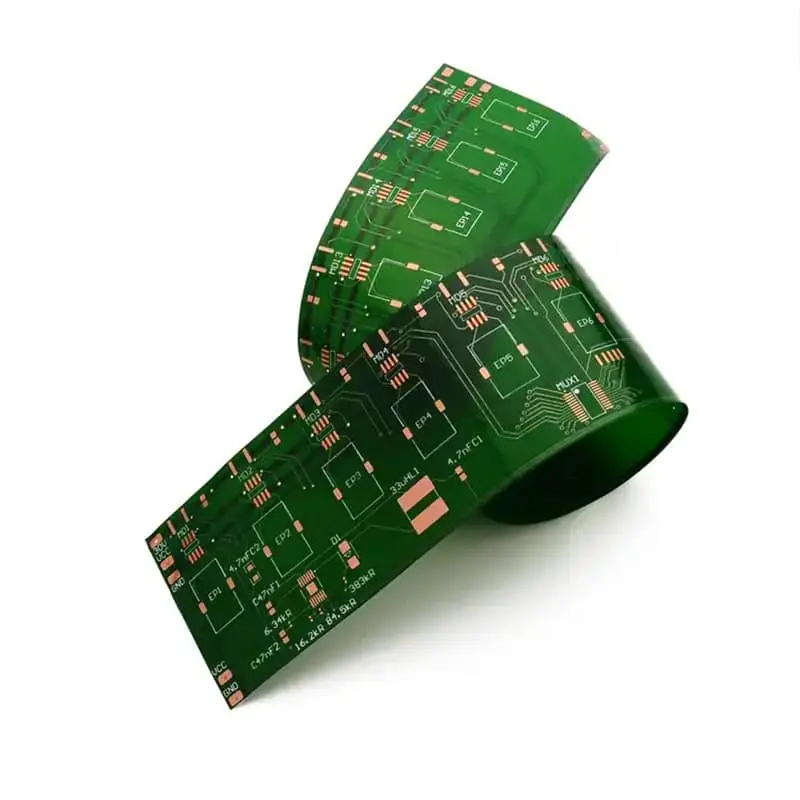

An FPC, also known as flex PCB or flex circuits is a specially designed circuit board characterized designed with flexible construction. The main difference between FPC and PCB is that the electronic devices are mounted on flexible plastic substrates. FPCs are commonly used in small electronic devices. So, rather than building devices that the components have to comply with the circuit board size, an FPC flexible PCB is usually thin therefore working perfectly in small spaces.

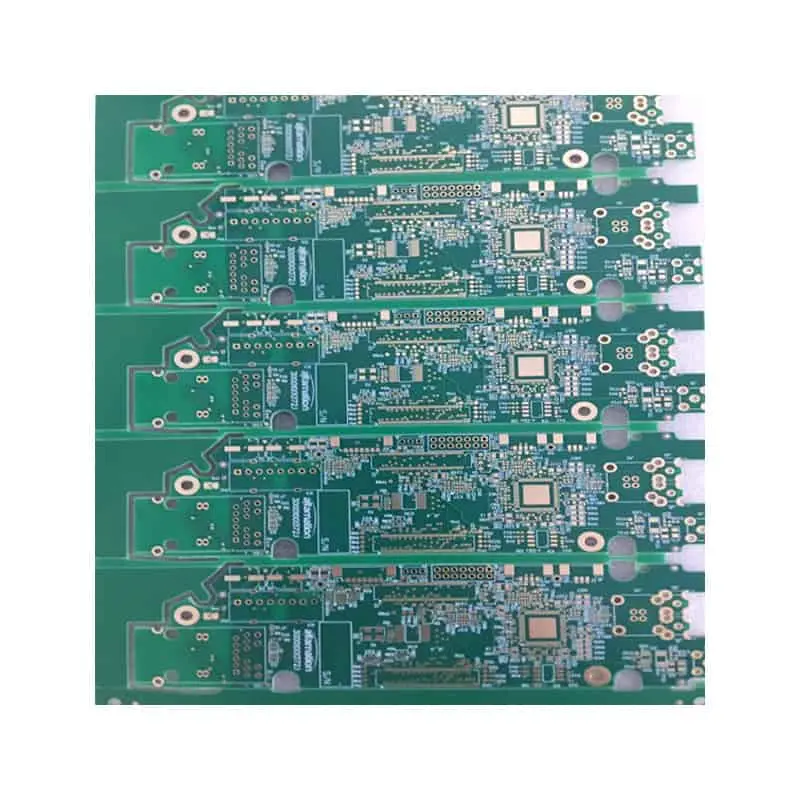

Because of its flexibility, design, and uniqueness, there are numerous options that manufacturers have come up with. That includes single-layer and double-sided FPC to multilayer FPC flexible PCB. Additionally, FPCs offer greater heat dissipation than PCB counterparts. So, how do you tell an FPC PCB is right for your project? One thing about FPCs is that they are made using flexible substrates. So, in this article, you will learn more about them and their main factors in PCB manufacturing.

What is the difference between FPC and PCB?

What is the difference between FPC and PCB?

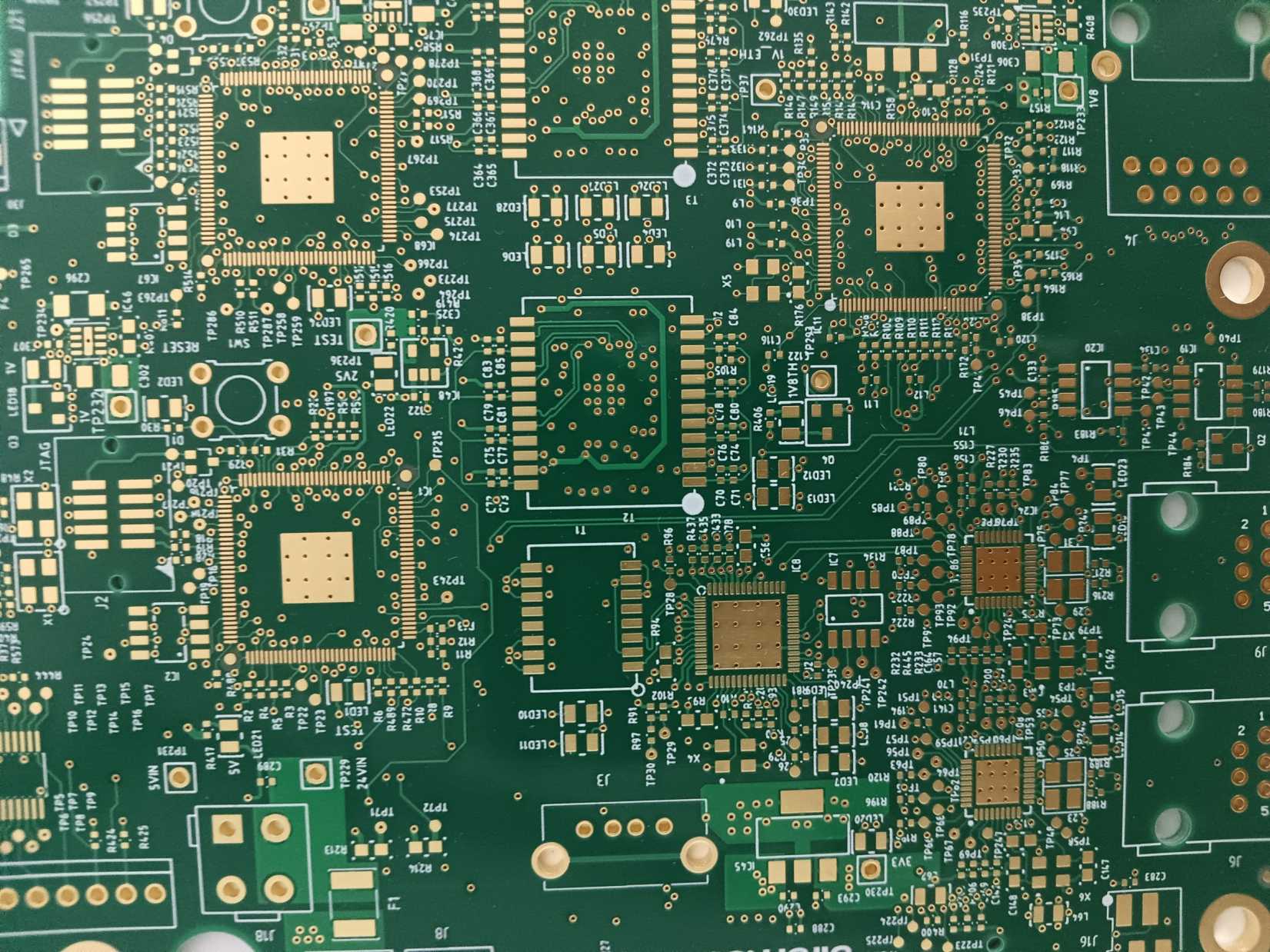

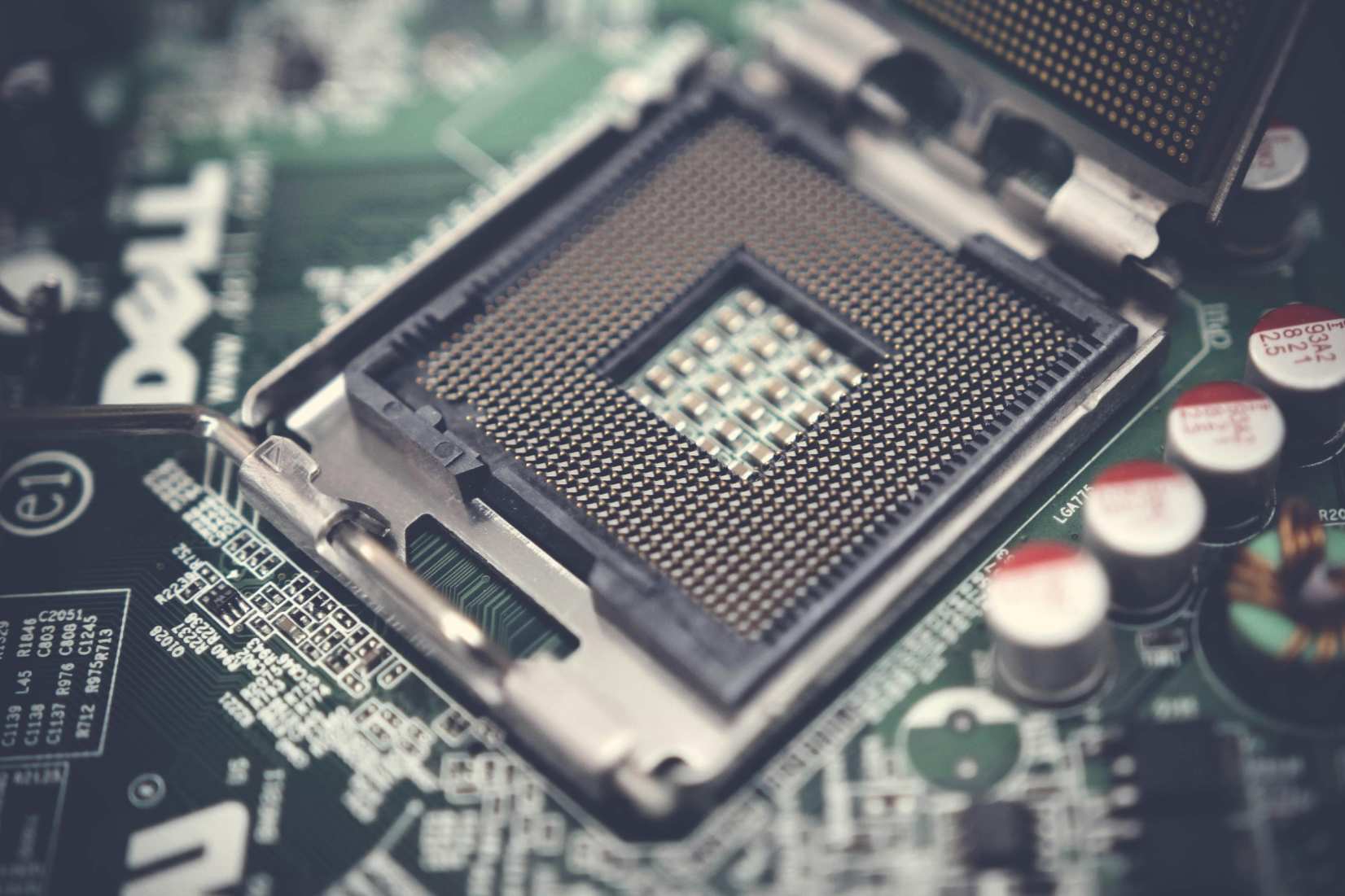

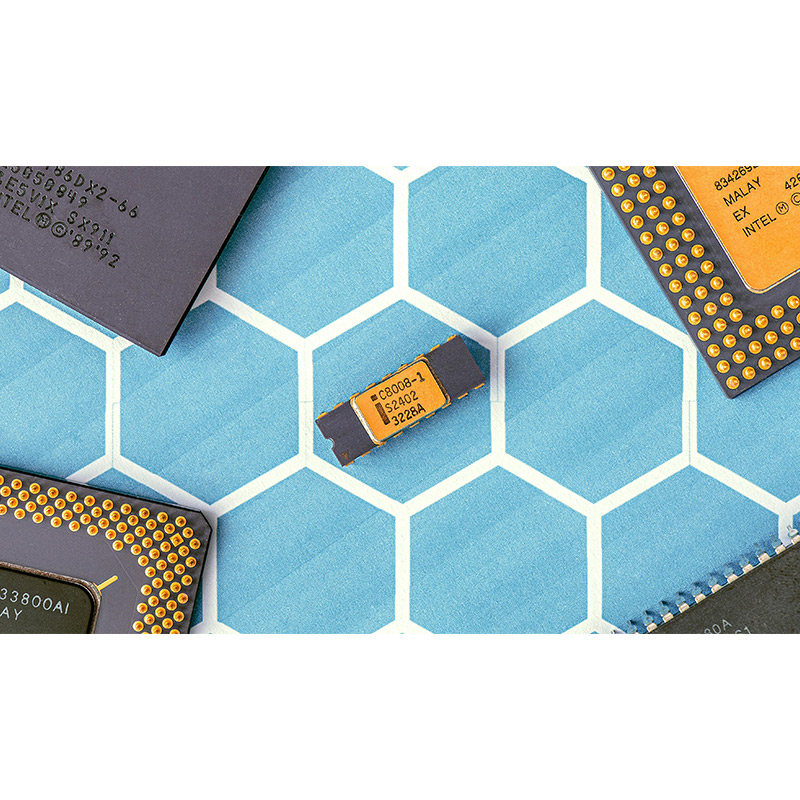

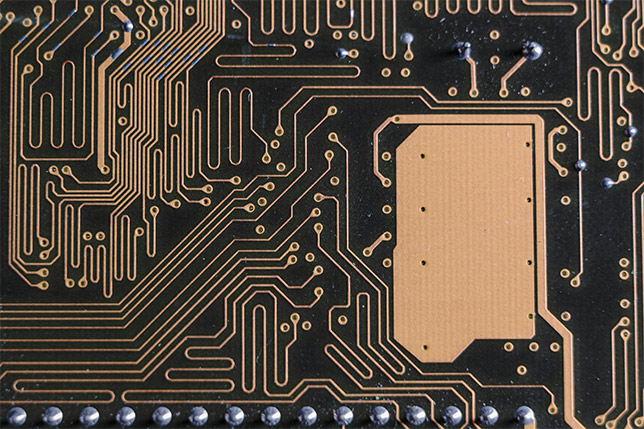

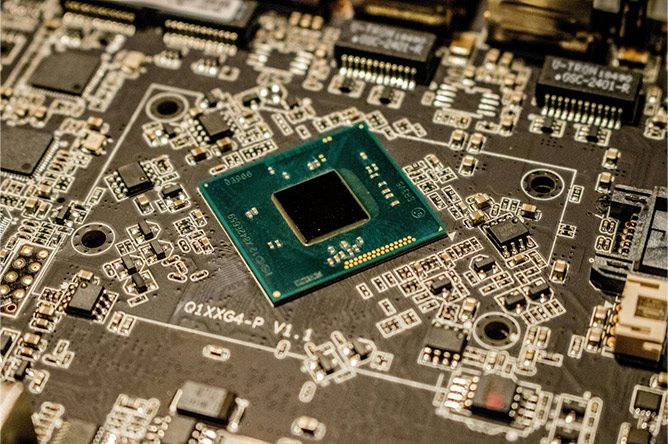

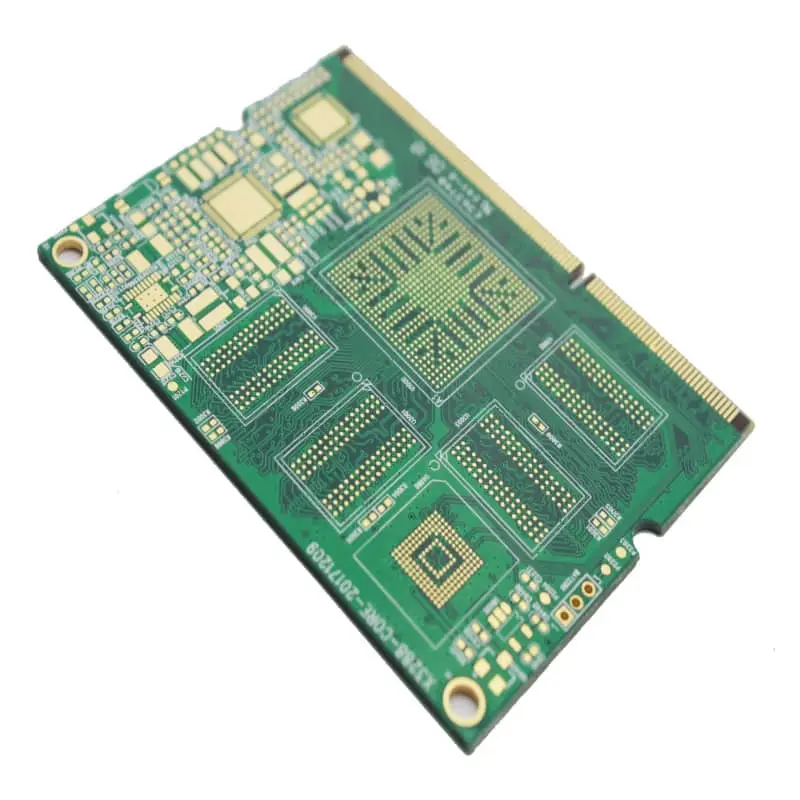

Printed circuit boards (PCBs), also known as hard boards are important electronic components that use FR4 as their base material and cannot bent. They are also known as hard boards and are generally used in places that don’t need bending such as mobile phone motherboards.

For FPC, they are a kind of PCB but a bit different from traditional PCBs. We can also call them soft boards. FPC uses PI as its base material. This material can easily bent and be flexed. Though it needs repeated flexing, the current technology offers more than that. At present, smartphone companies are thinking about adapting to key technology, more bending prevention, and FPC plays a major role.

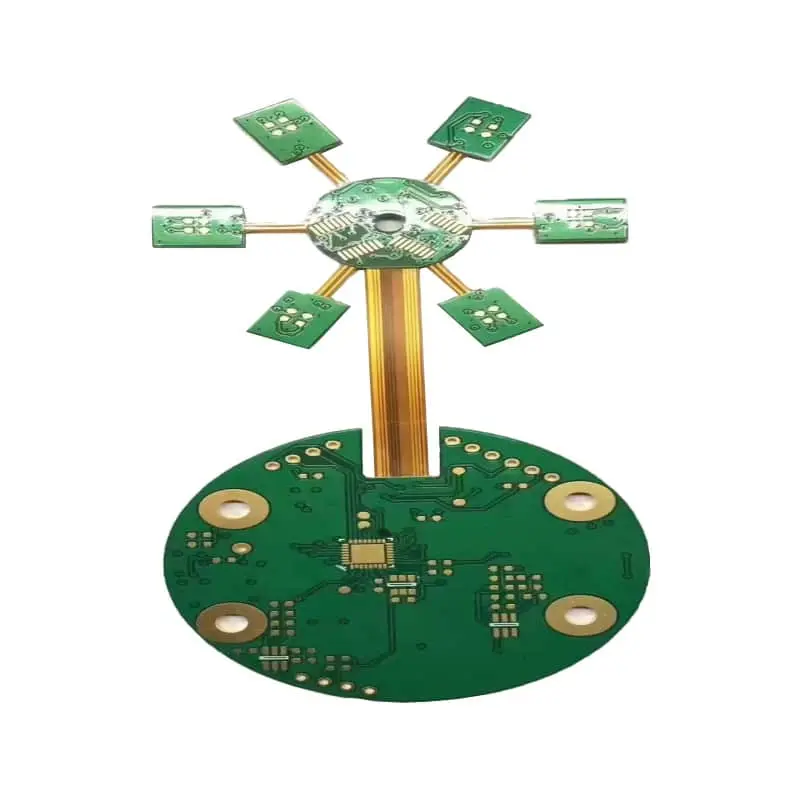

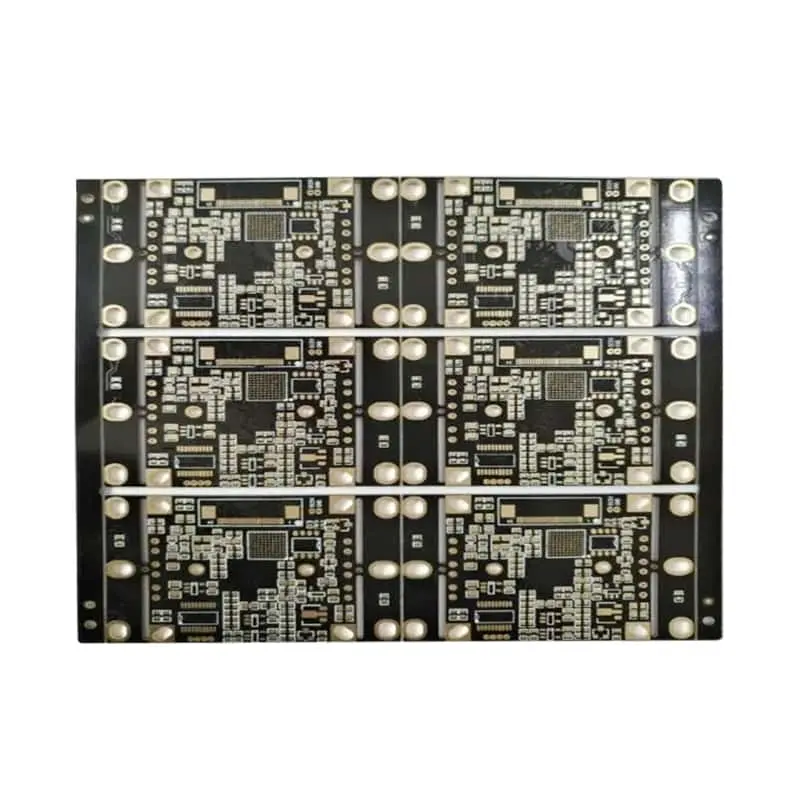

So, if you have been stranded whether to go for an FPC or PCB, with the way technology is taking form, FPC flexible PCB seems to be the future. That is why, at HAODA ELECTRONIC Co., we have multilayer FPC flexible PCB already in place.

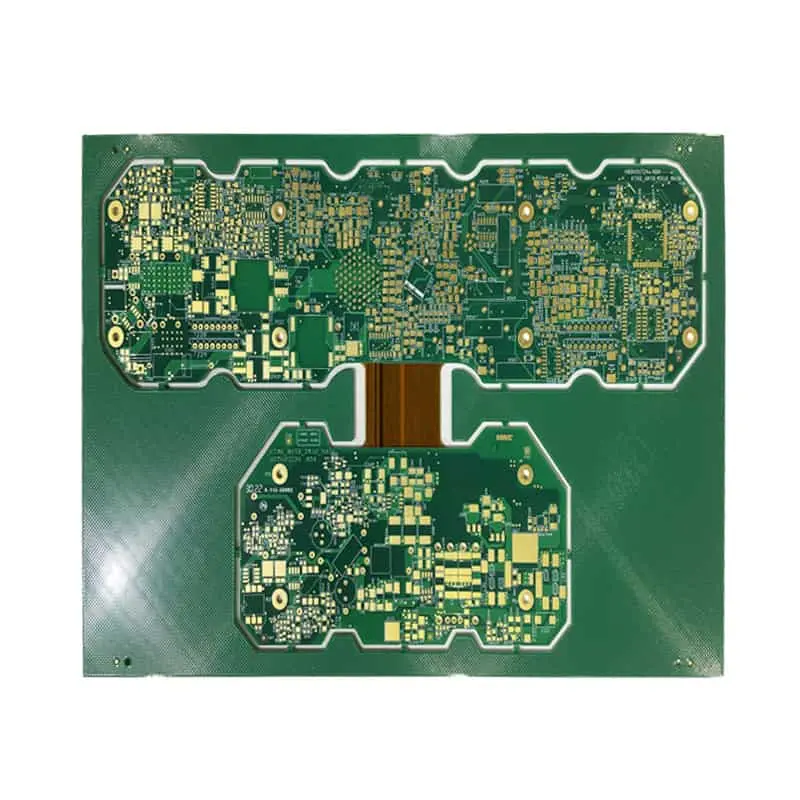

Our double-sided flexible boards have conductive patterns and metalized holes that connect patterns on both sides to form a conductive path. This has allowed flexibility in design and also in use. So, you can rely on our multilayer FPC for your projects.

Main Material for FPC Flexible PCB

Usually, the main material used is polyimide(PI) film, an applied substrate material. The substrate materials film is picked based on cost and performance. And since we are committed to offering high-quality FPCs, we use PI for our products. The substrate material for FCCL covers PI.

This is a thermosetting resin that doesn’t reach a temperature to soften or flow. However, it maintains its elasticity and flexibility after thermal polymerization. We use PI because of its high thermal resistance and compatibility test which makes them outstanding.

Conclusion

FPC PCBs have lots of benefits in different industries. Not only do they use less material, they also have lower replacement costs and less packaging. So, generally, FPC flexible PCB offers numerous possibilities especially in products and design as it combines the best connectors, wires, cables, and PCB qualities at once. HAODA ELECTRONIC Co. offers different FPCs all at pocket-friendly prices. For further information, you can get a free quote with us today.