When it comes to contemporary electronics manufacturing, the application of AI to the SMT PCB assembly process can be considered a step forward. This development not only improves the speed and accuracy of the PCB assembly but also meets the current trend of the electronics manufacturing industry in seeking automation solutions that can produce quality PCBs at a large scale.

What is an AI SMT PCB?

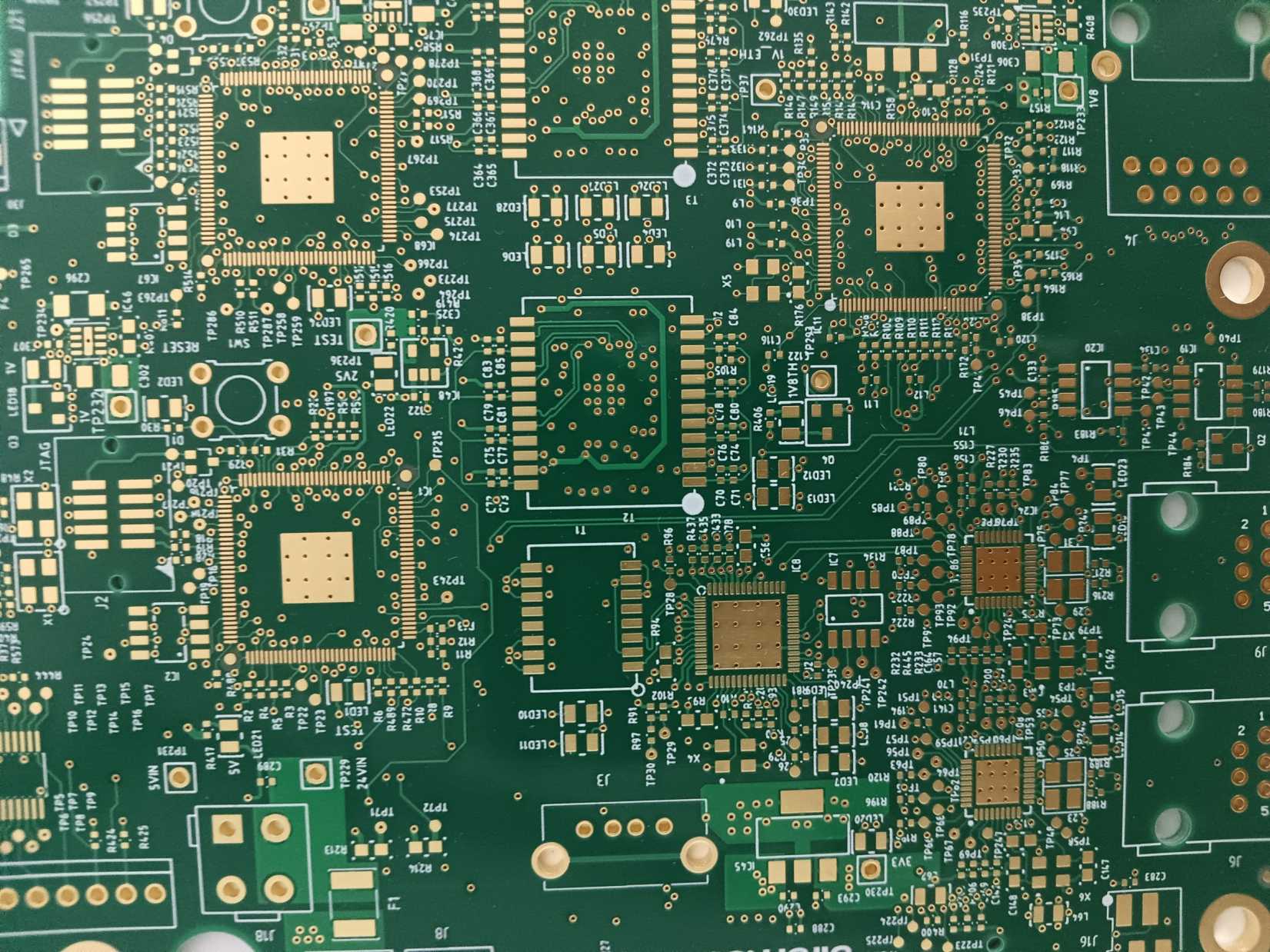

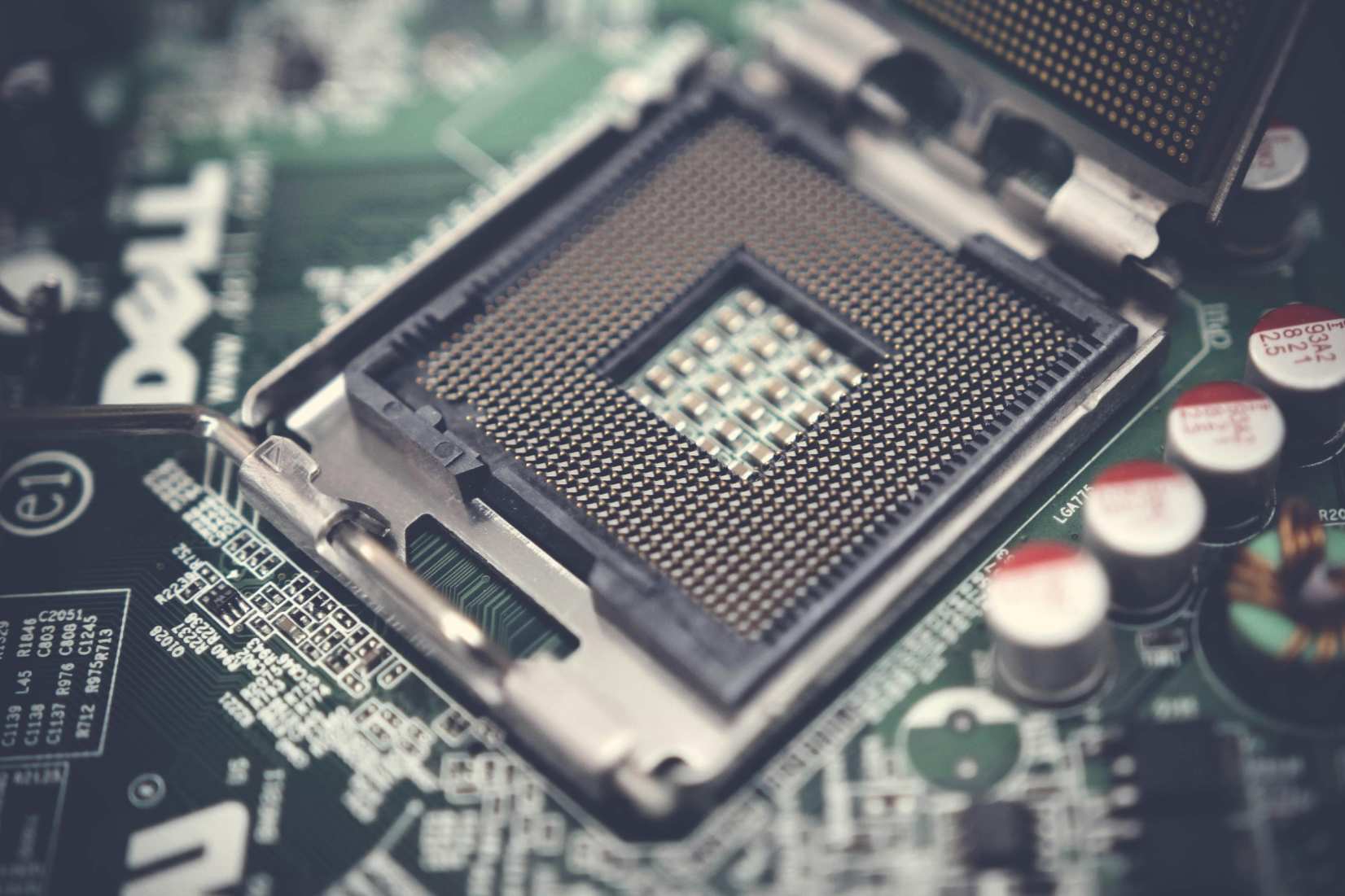

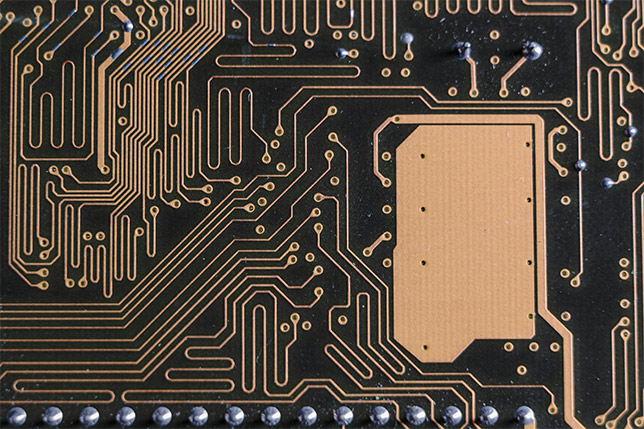

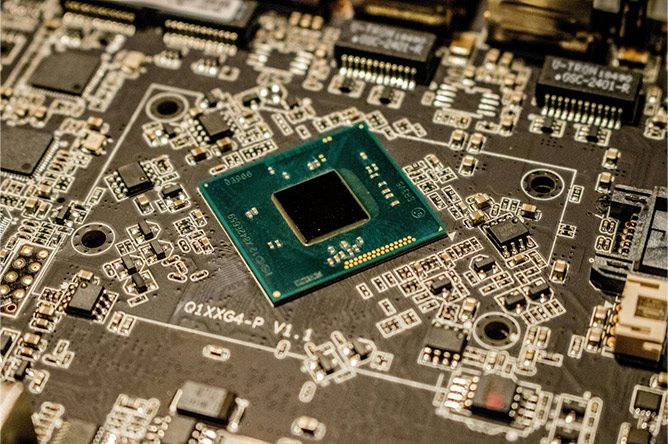

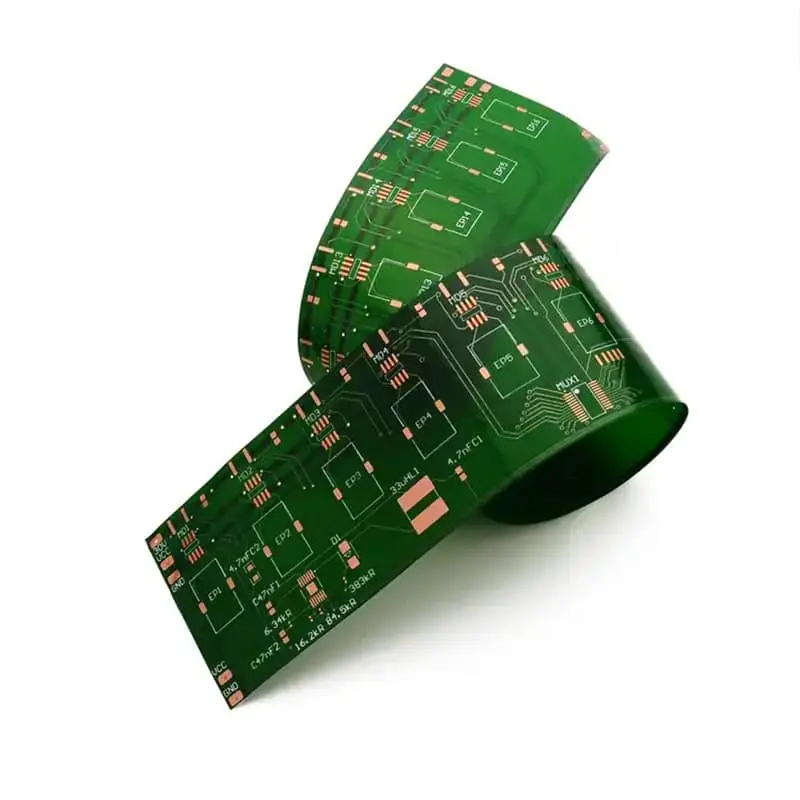

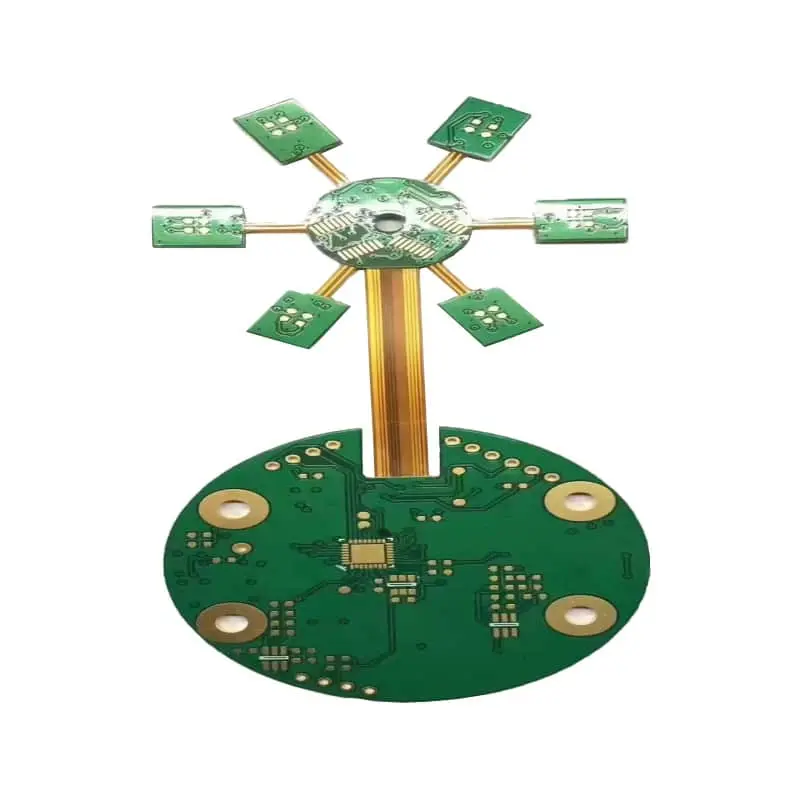

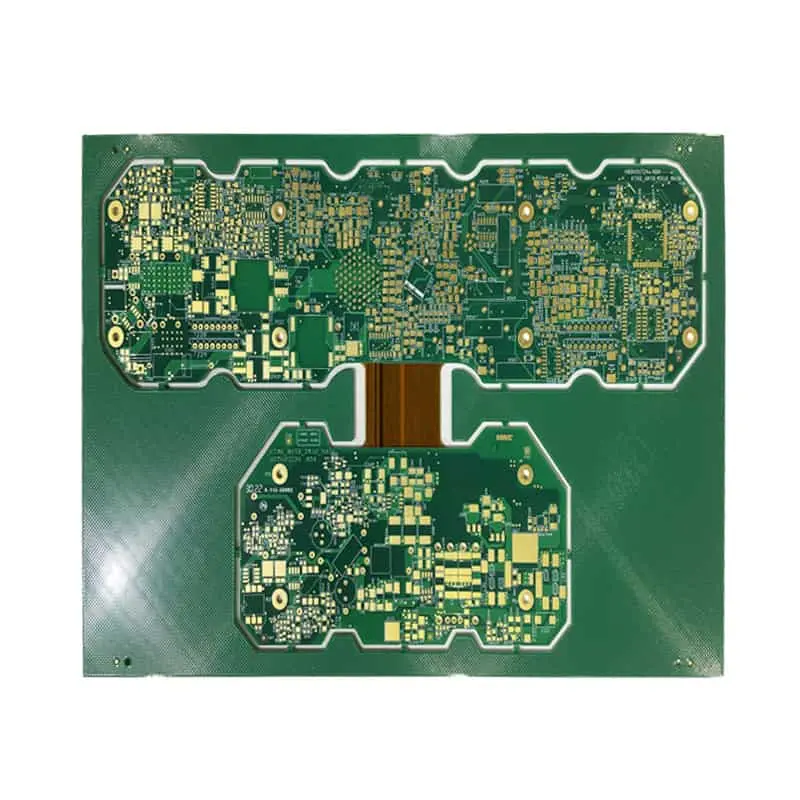

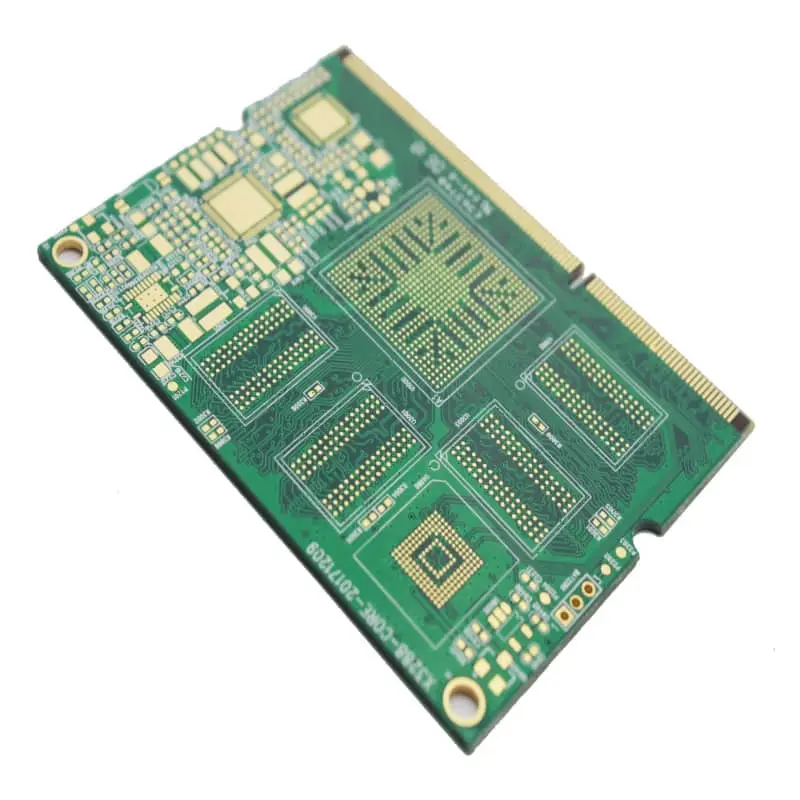

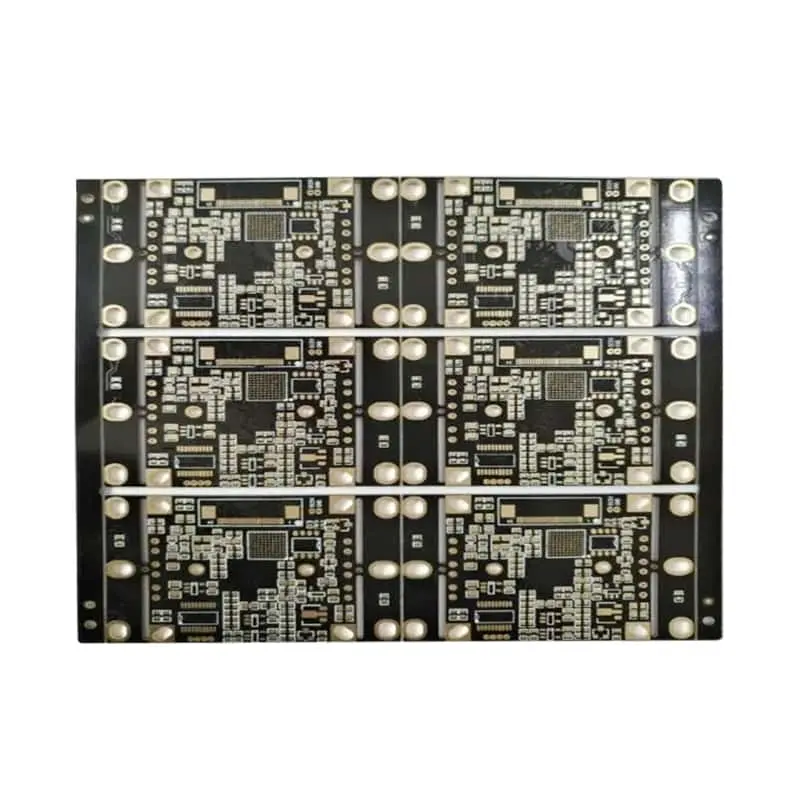

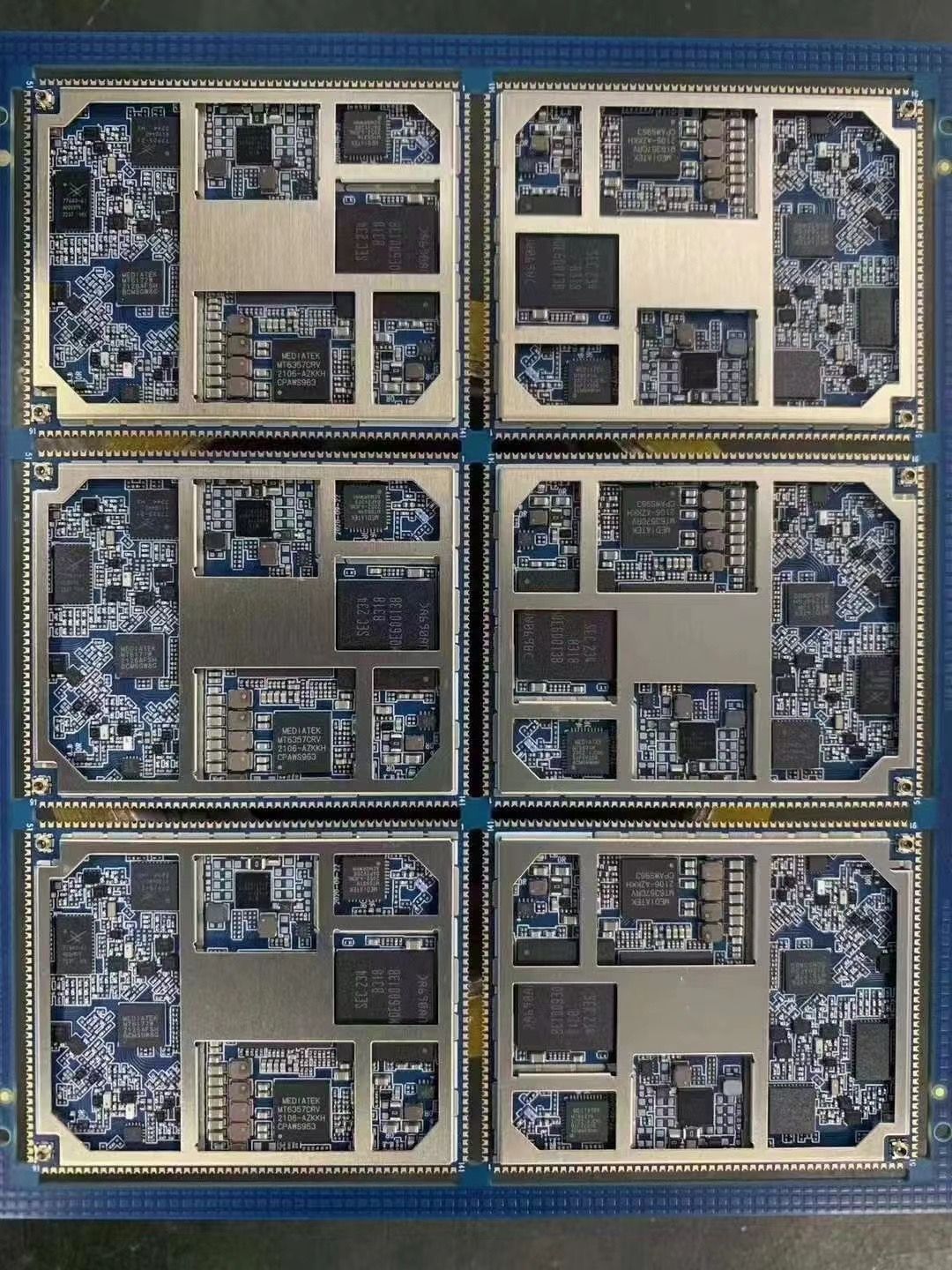

An AI SMT PCB refers to applying Artificial Intelligence within the Surface-Mount Technology Printed Circuit Board assembly process. Surface-mount technology involves placing electronic components directly onto the PCB surface rather than through-hole components. This method offers several advantages, including smaller PCB size, reduced weight, and improved electrical performance due to shorter interconnection paths.

Integrating AI into SMT PCB assembly introduces intelligent automation throughout the manufacturing process. AI algorithms optimize various stages, such as component placement, solder paste deposition, quality inspection, and defect detection. These algorithms analyze vast amounts of data in real-time, enabling machines to make informed decisions and adjustments swiftly and accurately.

Benefits of AI SMT PCB in Automated Assembly

Enhanced Precision: AI algorithms can achieve precise component placement and solder paste deposition with minimal error margin, ensuring consistent quality across batches.

Increased Efficiency: By automating repetitive tasks and optimizing workflows, AI reduces assembly time and labor costs while boosting overall production output.

Quality Assurance: AI systems’ real-time defect detection and quality inspection capabilities ensure that only PCBs meeting stringent quality standards are passed on for further processing, minimizing rework and waste.

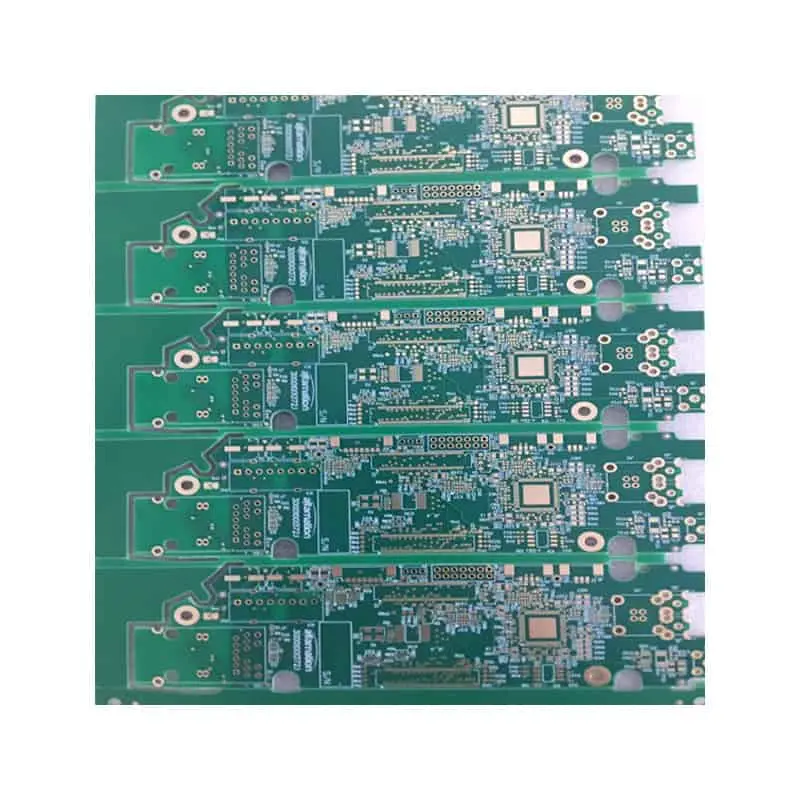

Scalability: AI-driven automation is scalable, allowing manufacturers to ramp up production volumes without compromising quality or efficiency.

Cost Savings: While initial investment in AI technology may be significant, the long-term savings in labor, reduced scrap rates, and improved yield justify the expenditure.

PCBCOMING’s Approach to AI SMT PCB

At PCBCOMING, we are at the forefront of integrating AI SMT PCB assembly processes. Our commitment to innovation and quality drives us to adopt the latest technologies that streamline manufacturing operations and elevate product reliability. By leveraging AI for automated assembly, we ensure that our customers receive PCBs that meet their exact specifications with unmatched precision and efficiency.

Our expertise in AI-enhanced SMT PCB assembly enables us to optimize every production stage. We achieve meticulous component placement and soldering through advanced machine learning algorithms, minimizing errors and maximizing throughput. This enhances the speed of delivery and upholds the highest quality control standards.

Our dedication to pioneering AI in PCB assembly reaffirms our commitment to delivering superior products that exceed industry expectations and ensure lasting partnerships with our valued clients.

Conclusion

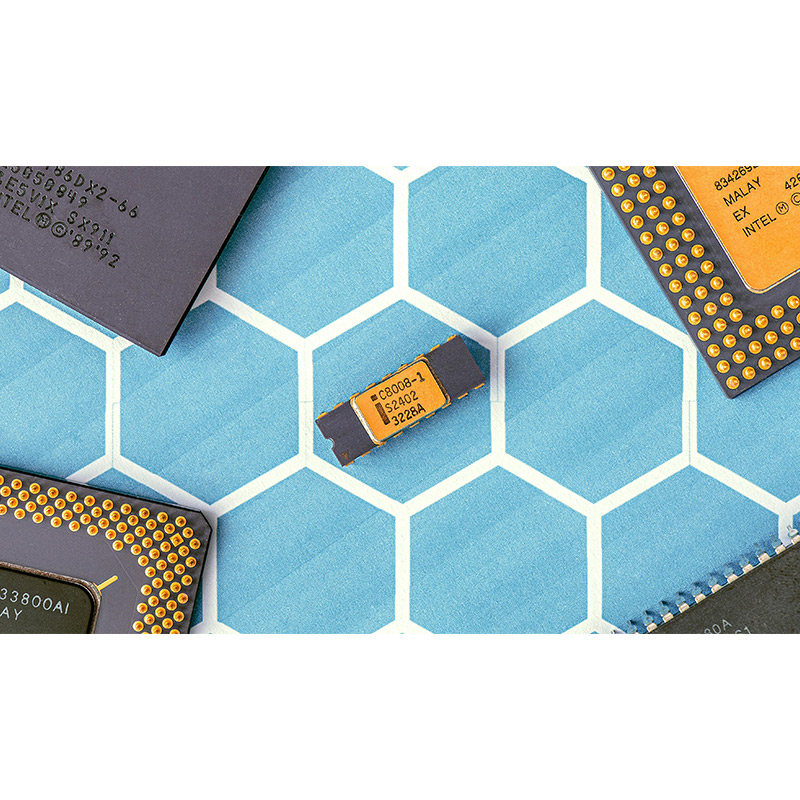

The evolution of AI SMT PCB in PCB automated assembly represents a pivotal advancement in electronics manufacturing. By harnessing the power of Artificial Intelligence, manufacturers can achieve higher levels of efficiency, precision, and scalability while maintaining stringent quality standards. As the industry continues to embrace automation and AI technologies, the future of PCB assembly looks promising, with increased capabilities to meet the demands of a rapidly evolving market.

For more information on how PCBCOMING integrates AI SMT PCB technologies into our manufacturing processes, visit our website at https://www.pcbcoming.com/.