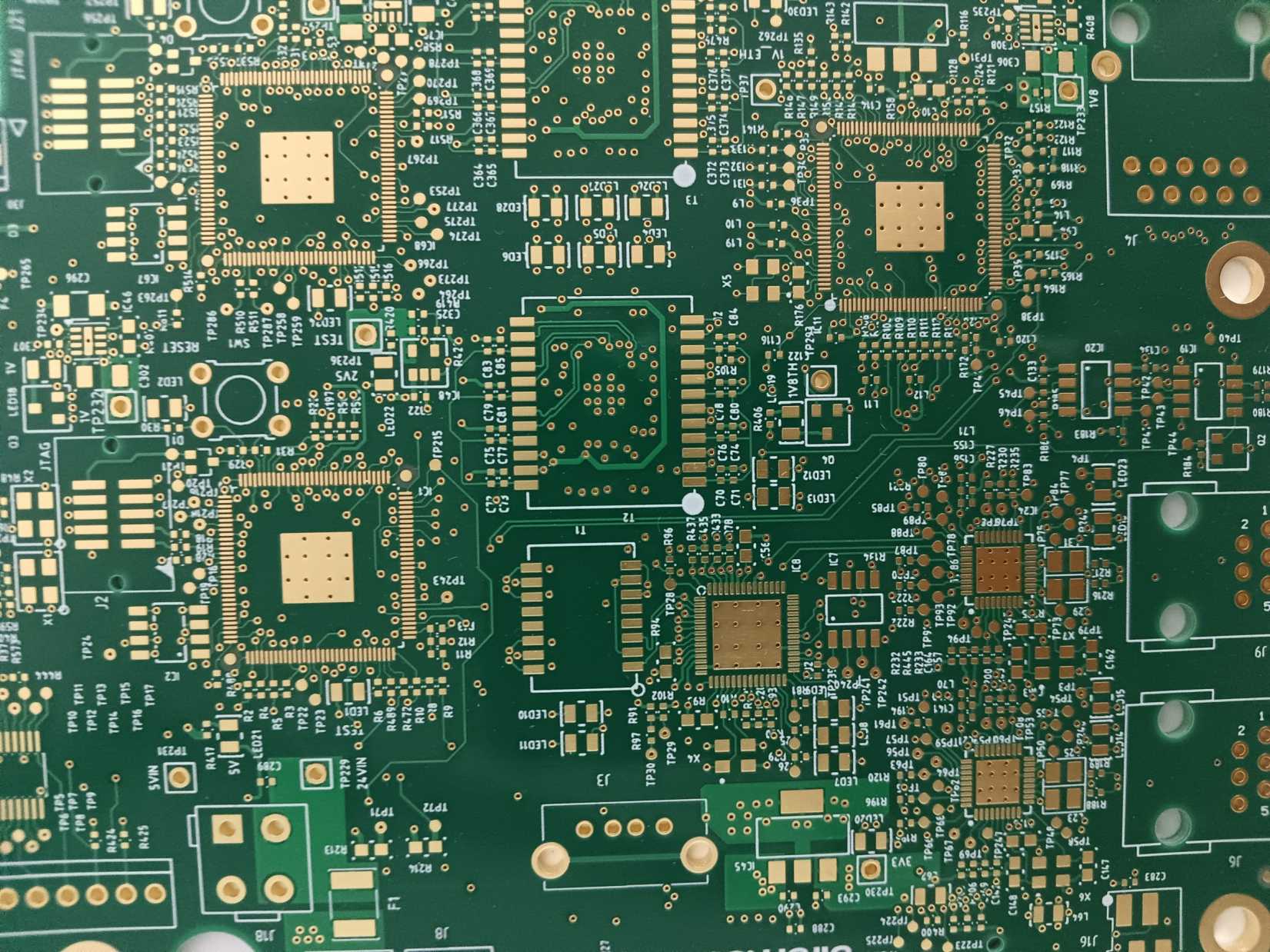

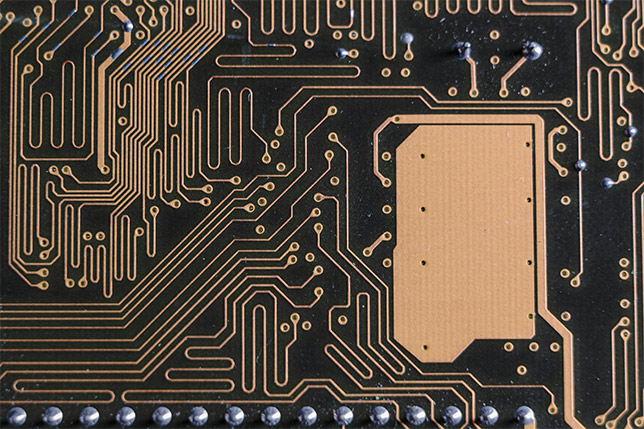

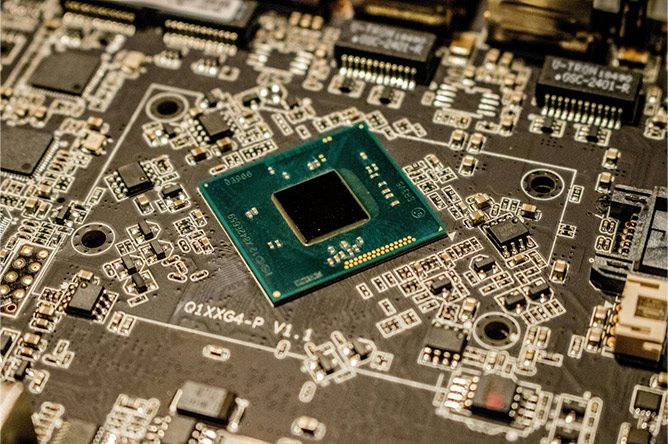

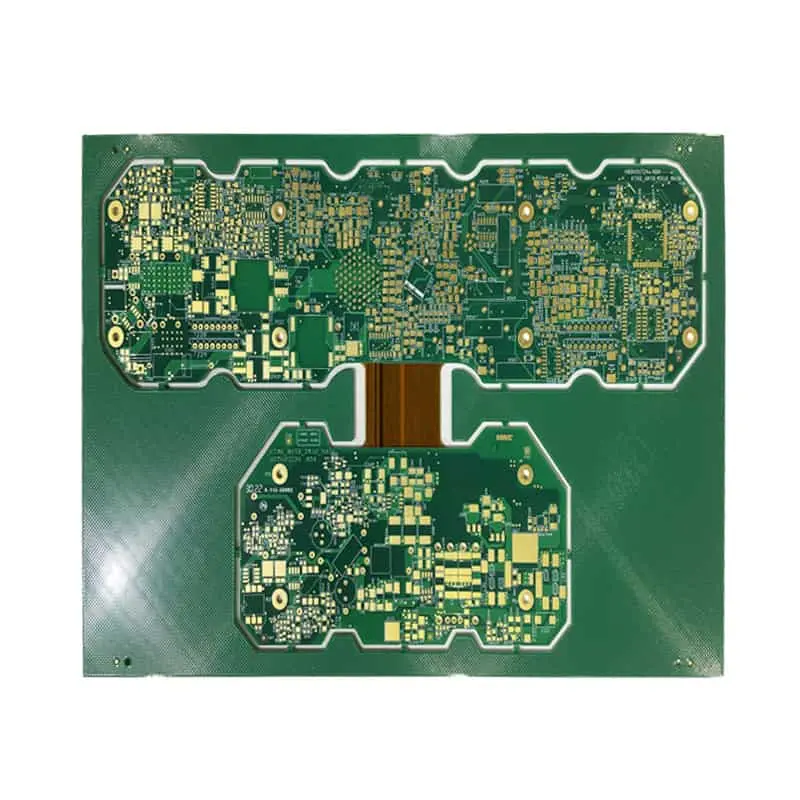

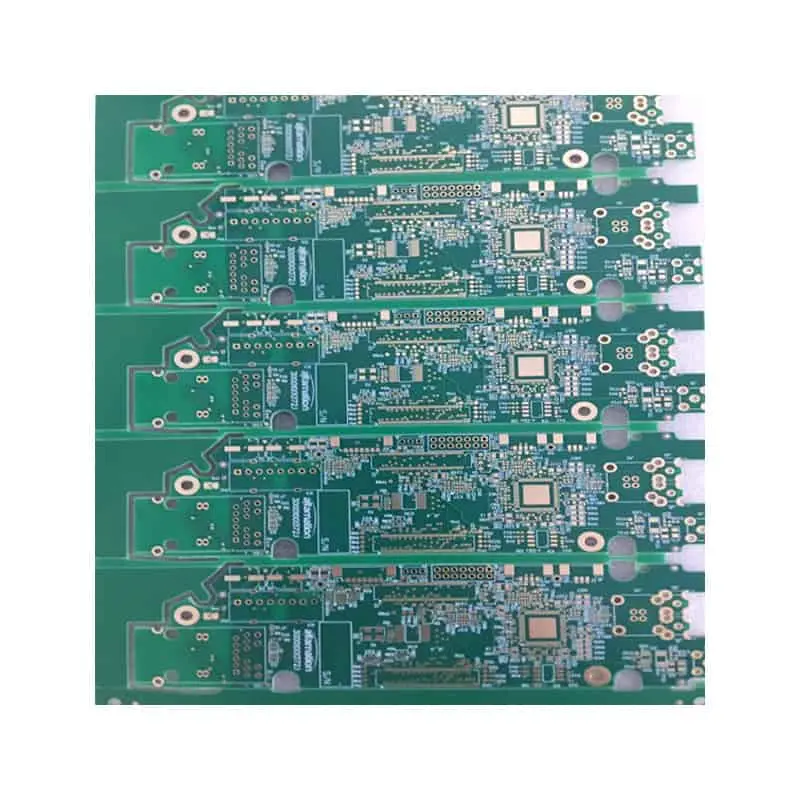

A PCB laminate is a fundamental component of a printed circuit board (PCB), providing the structural integrity and insulating properties necessary for the board’s functionality. The term “PCB laminate” refers to the base material used in the PCB, which consists of layers of fibrous reinforcement material (like fiberglass) and resin, often reinforced with copper foil. Understanding the role of PCB laminate and the considerations in its manufacturing process is crucial for anyone involved in electronics and PCB design.

What is Laminate in PCB?

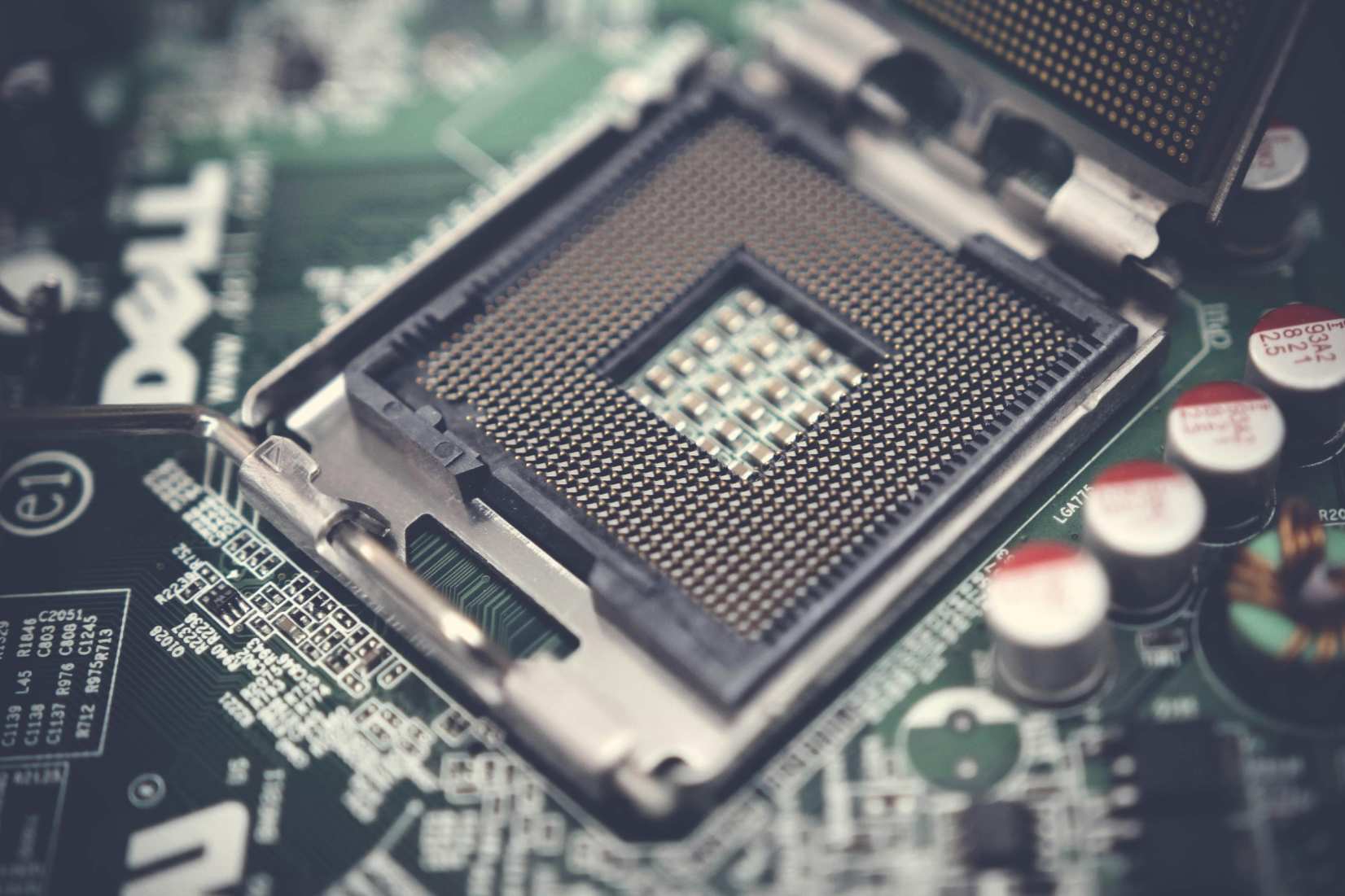

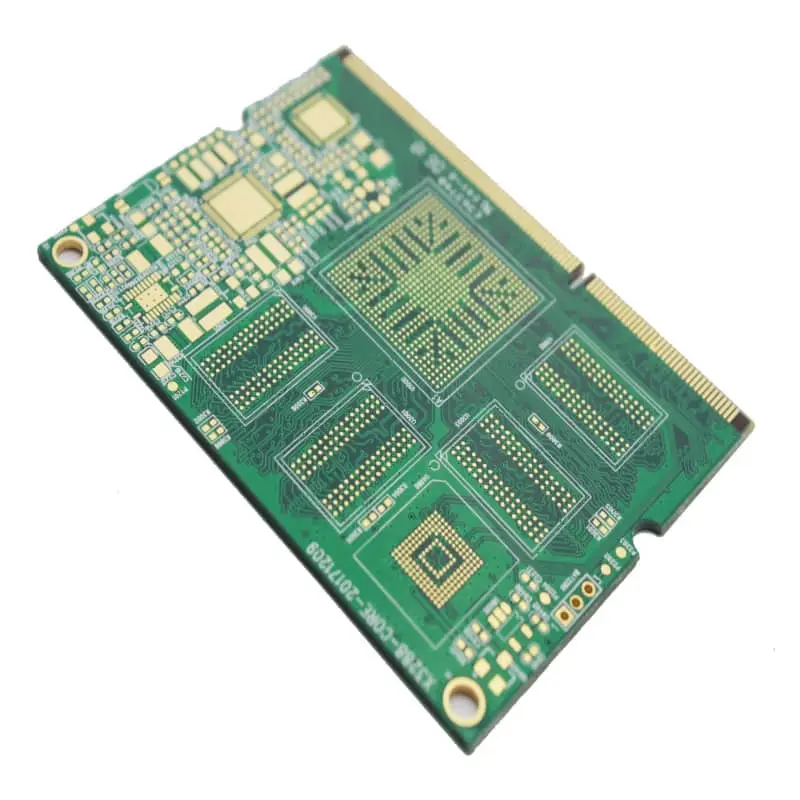

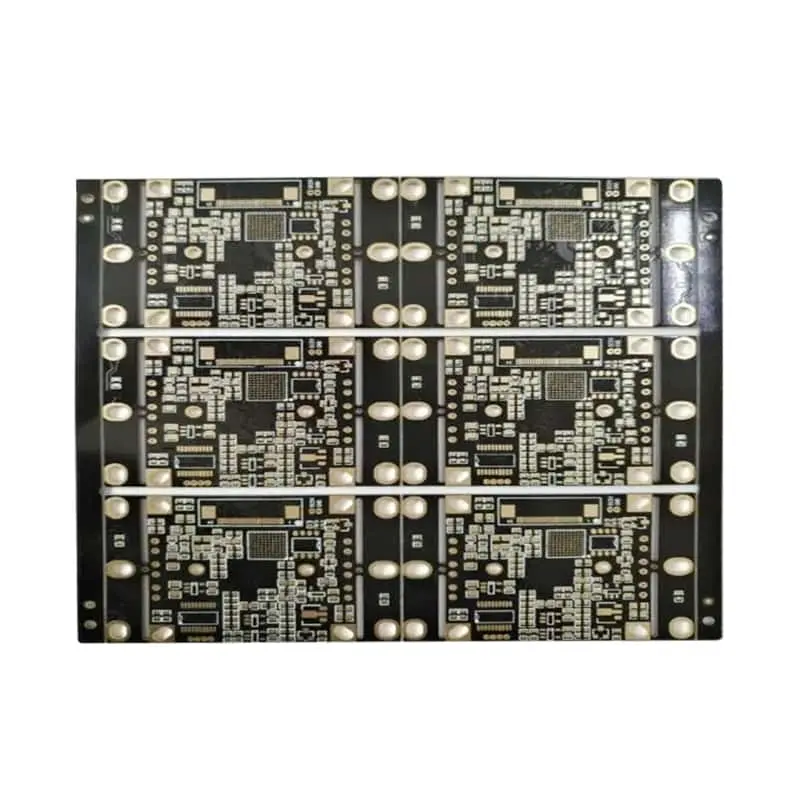

A PCB laminate forms the foundation of a printed circuit board. It is composed of several layers of materials, typically including a dielectric substrate and copper foils. The primary purpose of the laminate is to support the PCB’s conductive pathways and components while providing electrical insulation and mechanical stability.

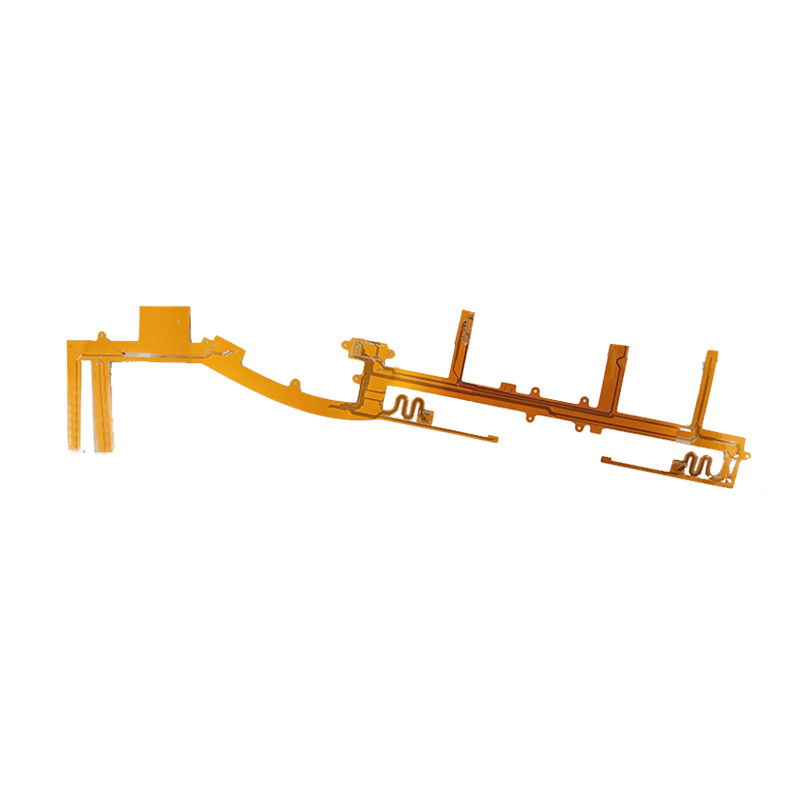

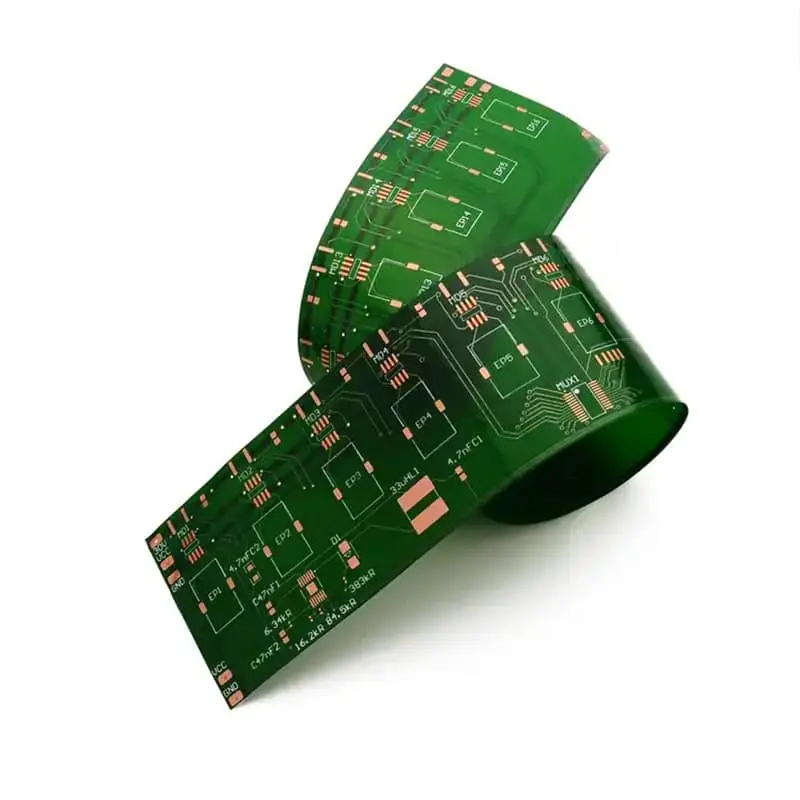

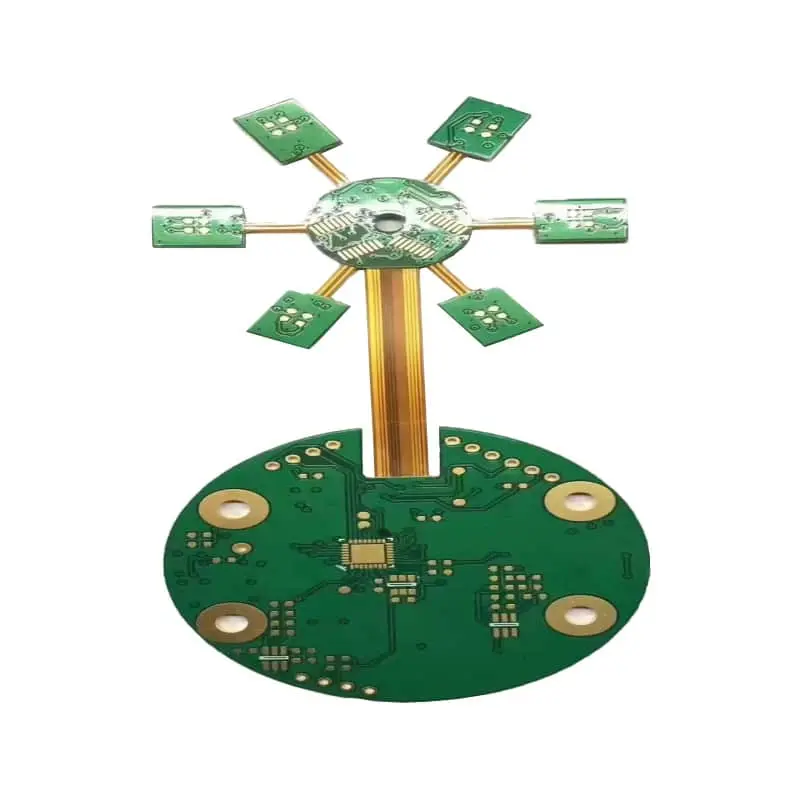

- Composition: The most common materials used for PCB laminate are fiberglass-reinforced epoxy resin (FR-4), polytetrafluoroethylene (PTFE), and other advanced materials tailored for specific applications. These materials were selected for their excellent electrical insulation properties, mechanical strength, and thermal stability.

- Functionality: PCB laminates are designed to withstand the heat and mechanical stress of soldering and other manufacturing processes. They also provide a stable platform for the intricate network of copper traces that form the PCB’s circuitry.

Manufacturing Process of PCB Laminate

The manufacturing process of PCB laminate involves several stages, each crucial for ensuring the final product’s quality and performance. Here’s an overview of the process:

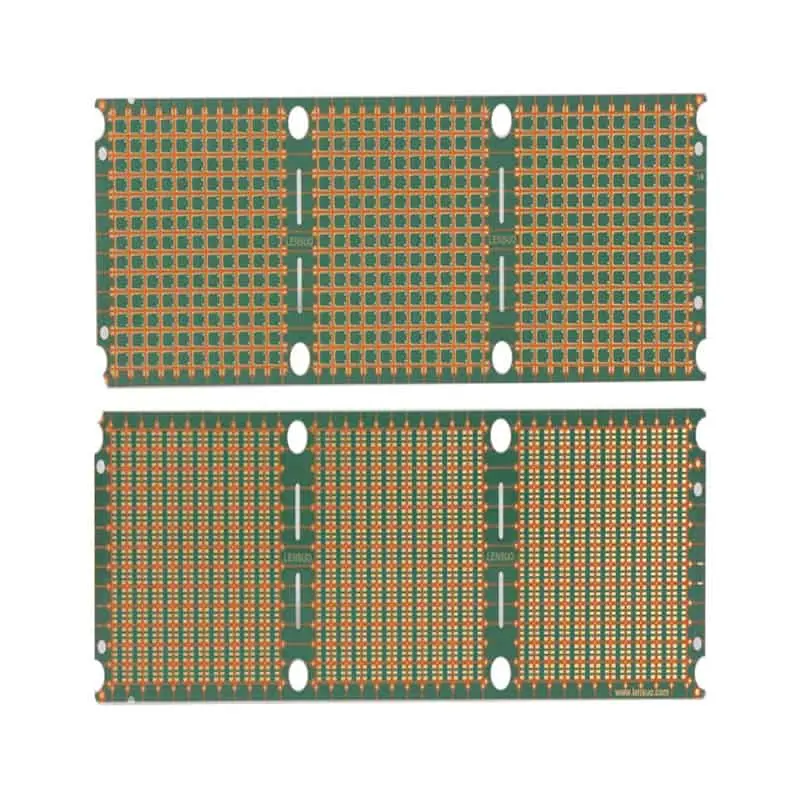

- Material Preparation: The first step involves preparing the base materials. Fiberglass cloth is impregnated with epoxy resin to form prepreg (pre-impregnated) sheets. These sheets are then partially cured to achieve the desired consistency.

- Lamination: Multiple layers of prepreg sheets and copper foil are stacked together and subjected to heat and pressure in a laminating press. This process bonds the layers into a solid laminate with the required thickness and properties.

- Curing: The laminated stack is fully cured in an oven to enhance its mechanical and thermal properties. The curing process ensures that the resin fully hardens and the laminate attains maximum strength and stability.

- Finishing: After curing, the laminate is trimmed to the required size, and its surface is treated to ensure good adhesion for further processing, such as copper plating and etching.

Considerations in PCB Laminate Manufacturing

Several factors must be considered during the manufacturing of PCB laminate to ensure high quality and reliability:

- Material Selection: The choice of materials affects the laminate’s electrical, thermal, and mechanical properties. Selecting the appropriate resin and reinforcement material is critical for the intended application.

- Thickness Control: Maintaining consistent thickness across the laminate is essential for achieving uniform electrical performance and reliable mechanical support.

- Thermal Management: Effective thermal management is crucial for preventing warping and ensuring the laminate can withstand high temperatures during soldering and operation.

- Quality Assurance: Rigorous testing and inspection processes are necessary to detect and eliminate defects such as delamination, voids, and insufficient curing.

Conclusion

In conclusion, PCB laminate is the backbone of printed circuit boards, providing essential support, insulation, and stability. The manufacturing process of PCB laminate involves careful material selection, precise lamination, thorough curing, and meticulous finishing. Understanding these processes and considerations is vital for producing high-quality PCBs that meet the demands of modern electronic applications.

In conclusion, PCB laminate is the backbone of printed circuit boards, providing essential support, insulation, and stability. The manufacturing process of PCB laminate involves careful material selection, precise lamination, thorough curing, and meticulous finishing. Understanding these processes and considerations is vital for producing high-quality PCBs that meet the demands of modern electronic applications.

By leveraging the right PCB laminate materials and manufacturing techniques, designers and manufacturers can ensure their PCBs perform reliably in various environments, from consumer electronics to industrial and aerospace applications. Whether you are a seasoned engineer or new to PCB design, appreciating the importance of PCB laminate will enhance your understanding and capability in the field of electronics.