We often come across the term impedance control especially in relation to the PCBs. If you’re not an electrical engineer or familiar with the industry, you might be a bit confused as to what does it actually mean. But trust us, if you’re dealing with high-speed electronics, this concept is crucial.

You may think the impedance control it as being similar to a traffic signal of your printed circuit board (PCB). It makes sure that all signals within a circuit board flow smoothly and don’t cause any interruptions or distortions.

What’s the Big Deal with Impedance Control?

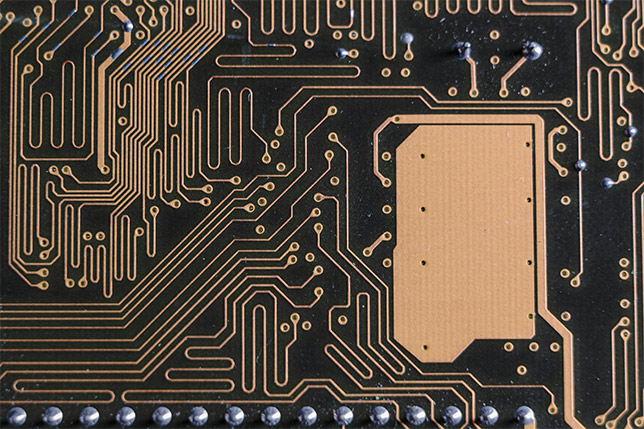

In simple terms, impedance is the resistance a circuit offers to the flow of alternating current (AC). If we continue with our traffic control example, you may say that tn the world of PCBs, it’s like the width of a highway: too narrow and you get a traffic jam, too wide and cars start bouncing around. Impedance control is all about making sure the “highways” on your PCB (the traces) are just the right width for the signals you’re sending through them.

Why Does Impedance Control Matter?

If you’re designing a simple circuit with low-frequency signals, you might not even notice impedance issues. But as signal speeds increase, things get trickier. Uncontrolled impedance can lead to all sorts of problems, like:

Signal Reflections: Like echoes in a canyon, signal reflections can bounce back and forth on your PCB, distorting the original signal.

Crosstalk: This is like two people talking over each other. Signals on adjacent traces can interfere with each other, causing errors.

Signal Loss: This is like a leaky pipe. Some of your signal energy can be lost due to impedance mismatches.

All these issues can lead to unreliable performance, or even worse, complete failure of your electronic device. And no one wants that, especially if you are in PCB related business.

How Do You Achieve Impedance Control?

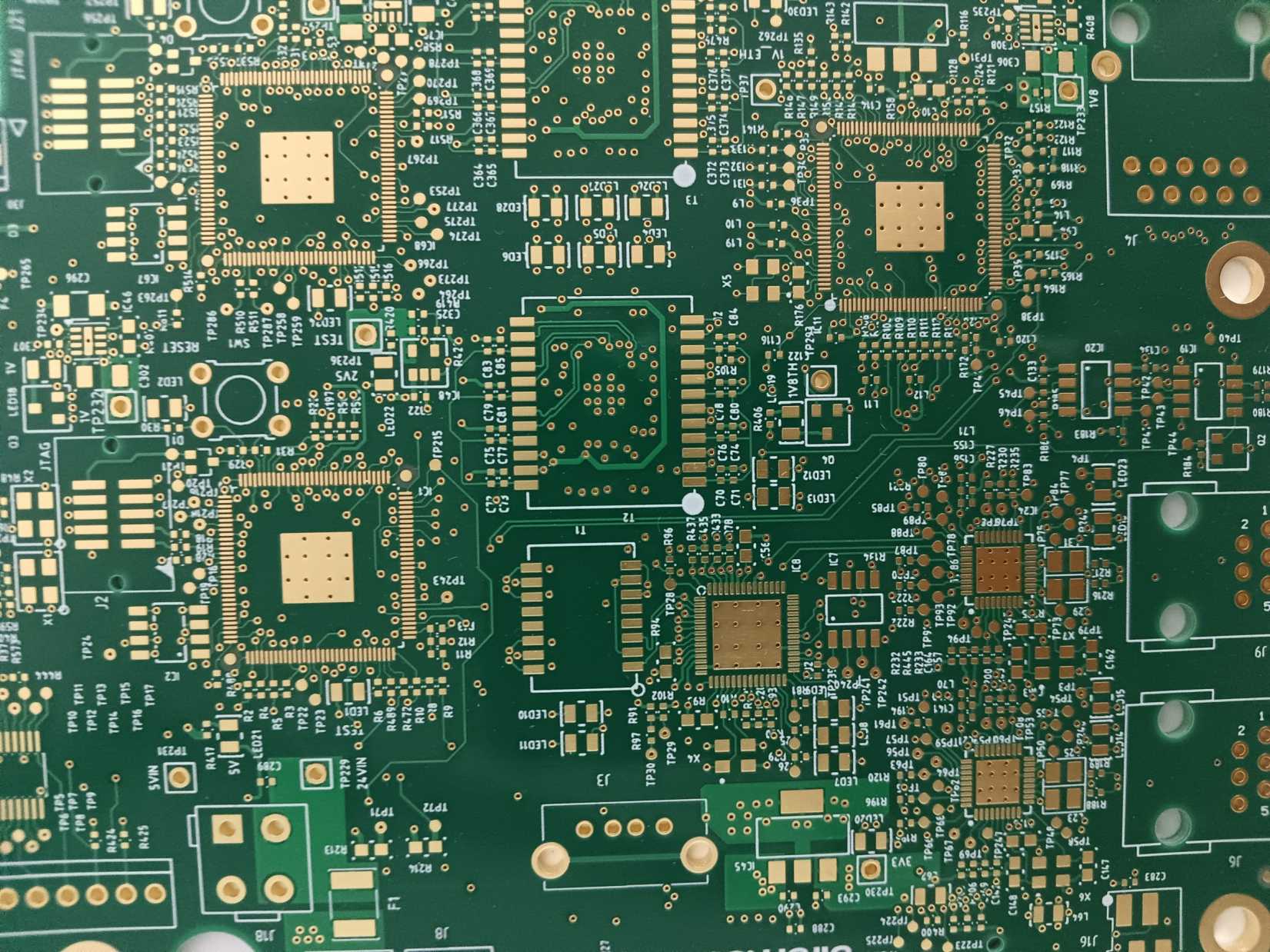

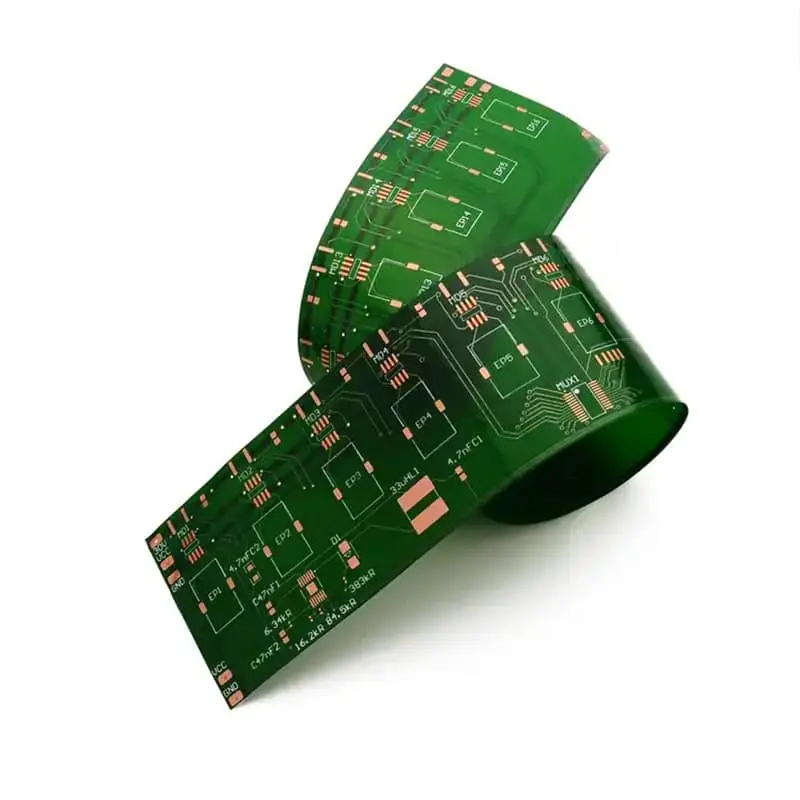

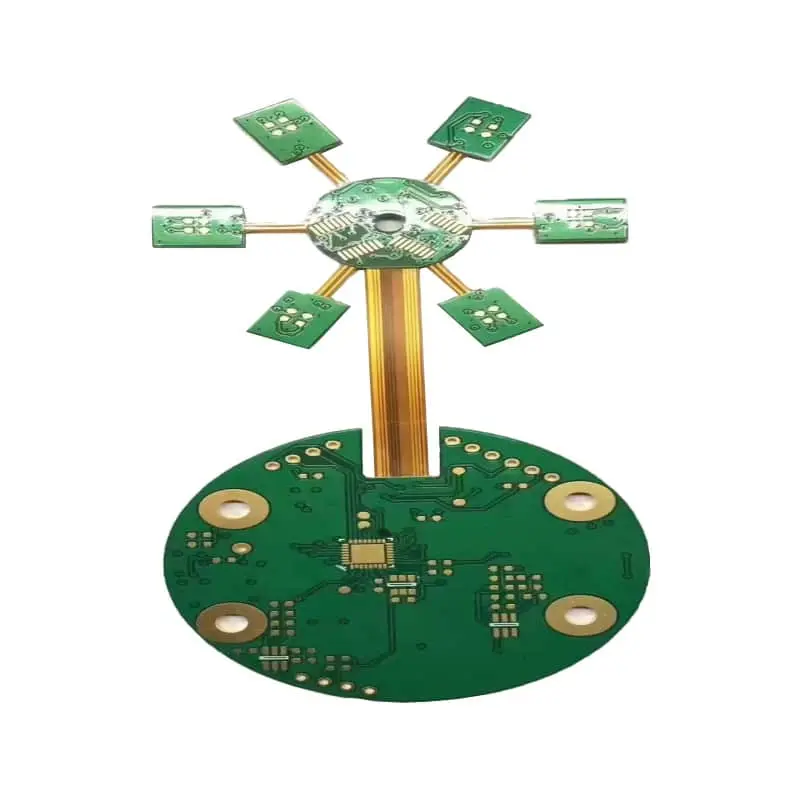

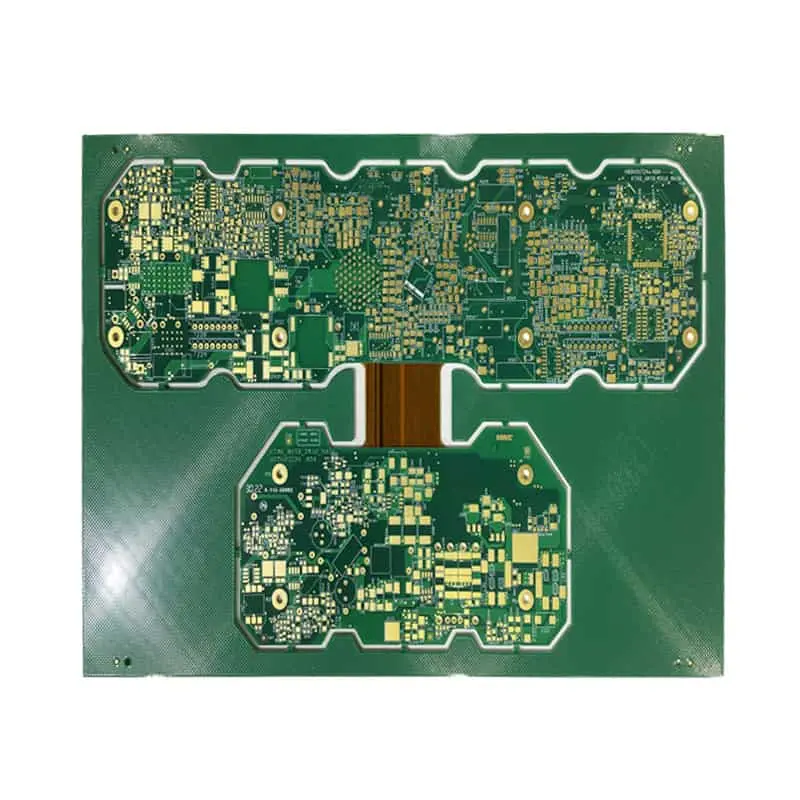

How do we achieve impedance control is not that difficult to understand, although it can get a bit technical. Impedance control involves carefully designing your PCB traces, taking into account factors like trace width, copper thickness, dielectric constant of the material, and even the distance between traces.

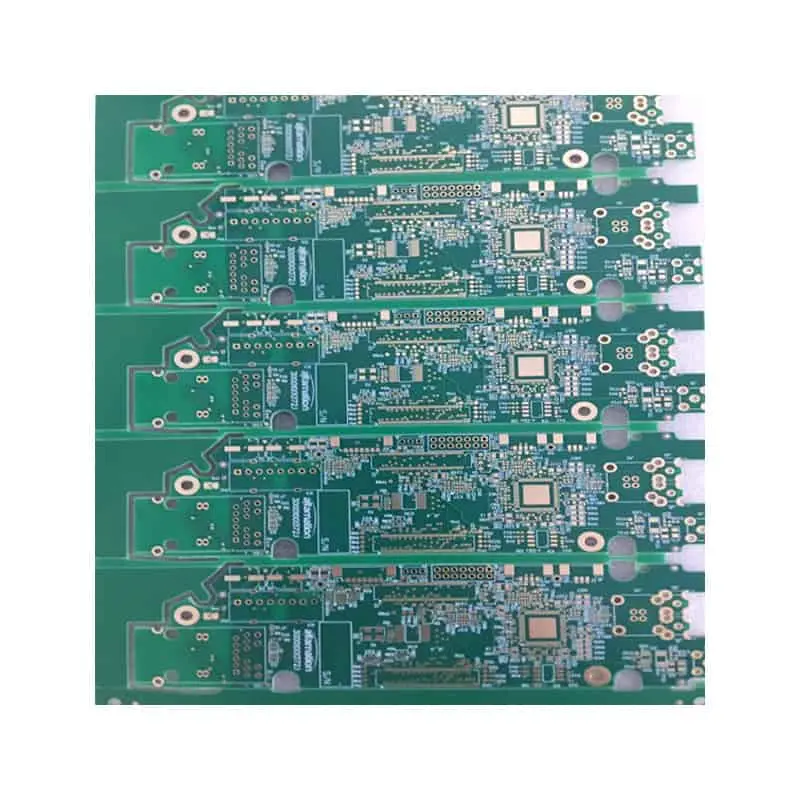

There are various software tools that can help you calculate the right impedance for your design, and experienced PCB manufacturers can ensure that the final product meets your specifications.

When Should You Worry About Impedance Control?

The higher the signal speed, the more critical impedance control becomes. Here’s a general rule of thumb:

Low-frequency signals (below 50 MHz): Impedance control is not usually a major concern.

Mid-frequency signals (50 MHz to 500 MHz): Impedance control starts to become important.

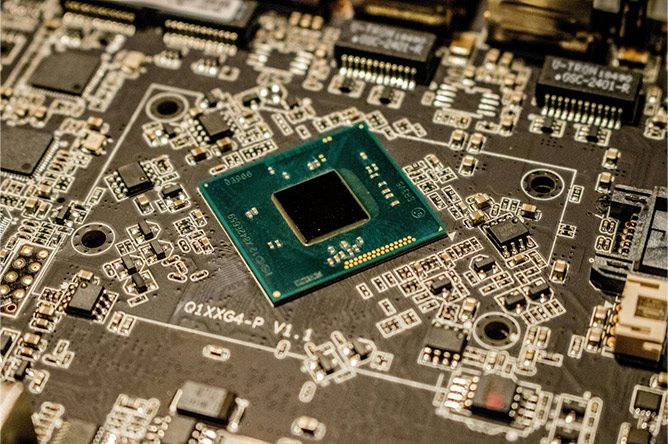

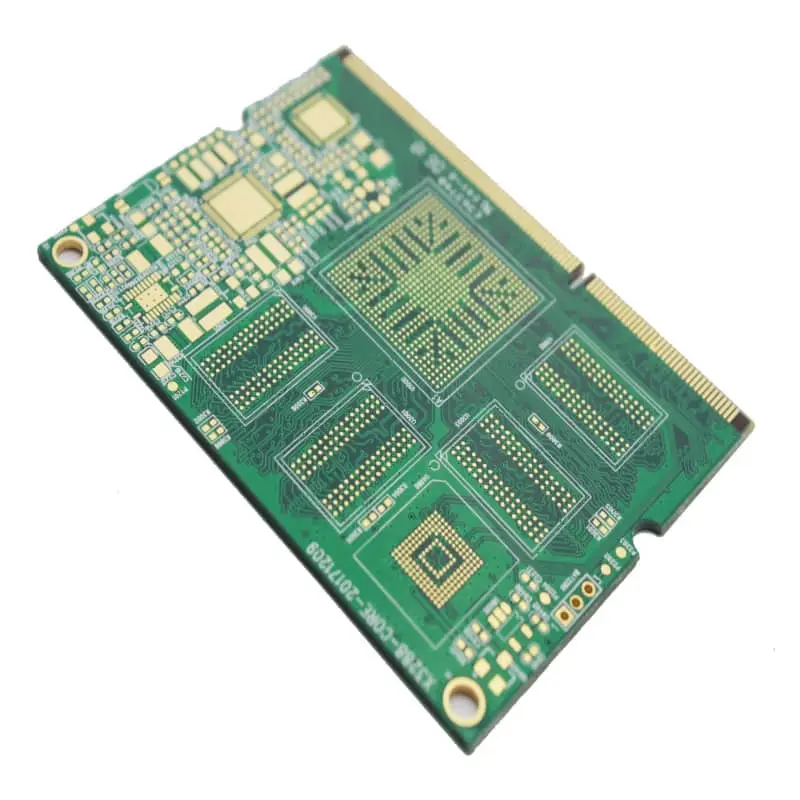

High-frequency signals (above 500 MHz): Impedance control is absolutely essential.

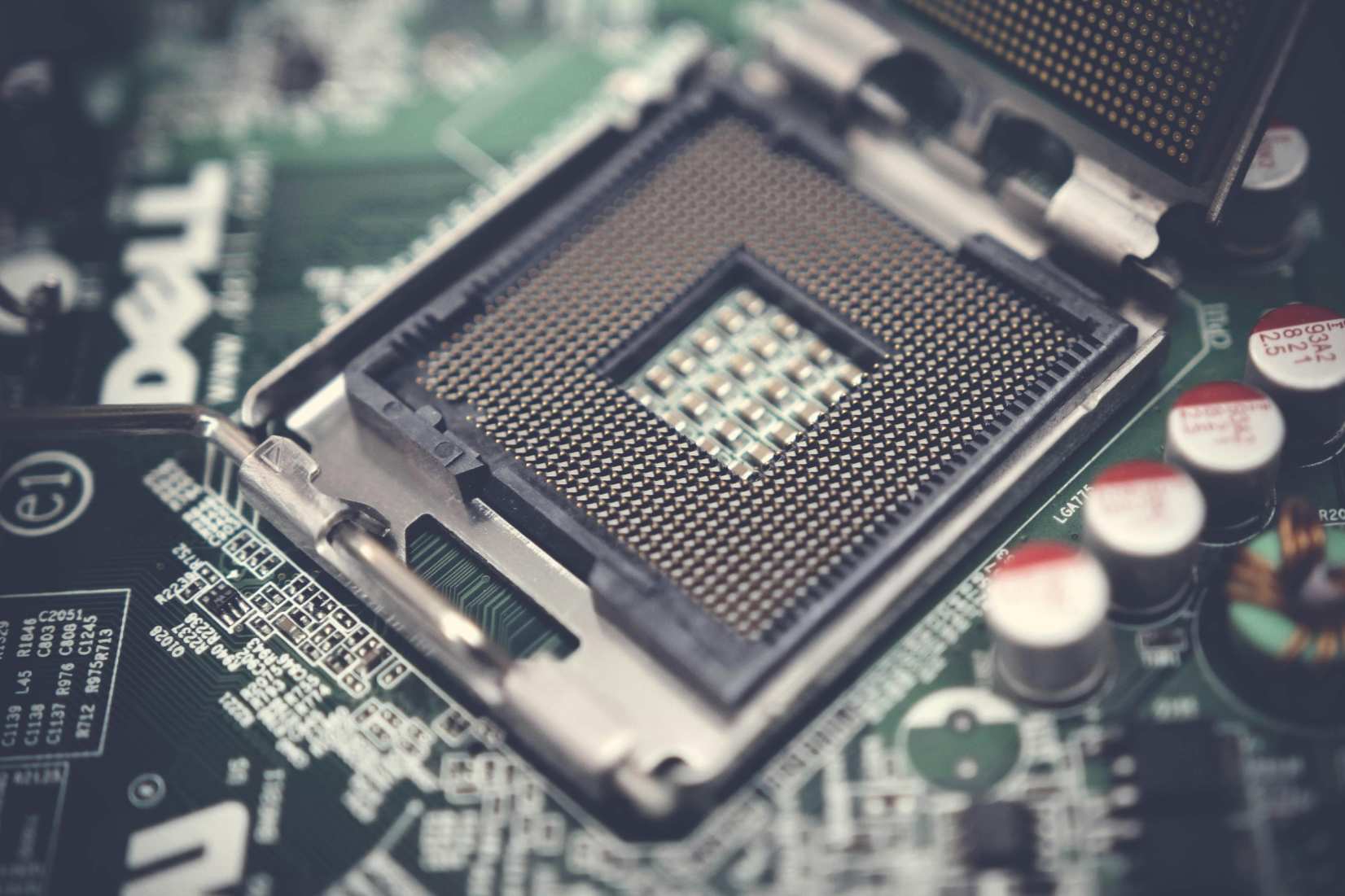

So, is Impedance Control Really That Important? In one word, yes! If you’re designing high-speed electronics, like computers, smartphones, or networking equipment, impedance control is non-negotiable. It’s the key to ensuring that your signals arrive at their destination clean, clear, and on time.

Remember, impedance control is not just about meeting industry standards—it’s about ensuring the reliability and performance of your products. So, the next time you’re designing a high-speed PCB, remember the importance of impedance control. It might seem like a small detail, but it can make all the difference in the world.